FAQS

Do you offer after sale service?

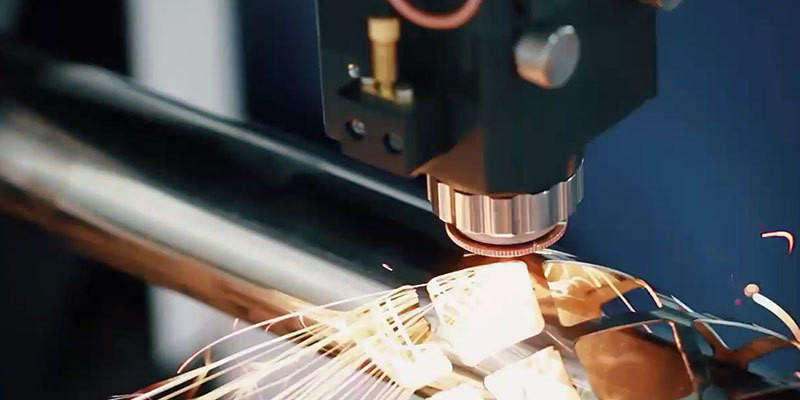

What are the advantages of laser welding machine?

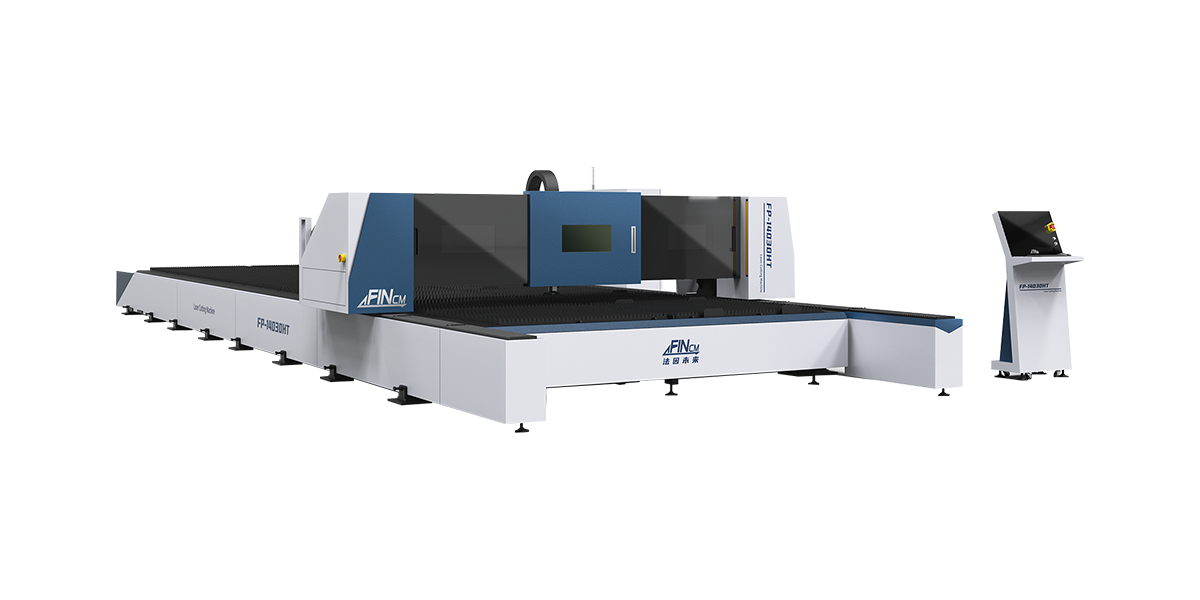

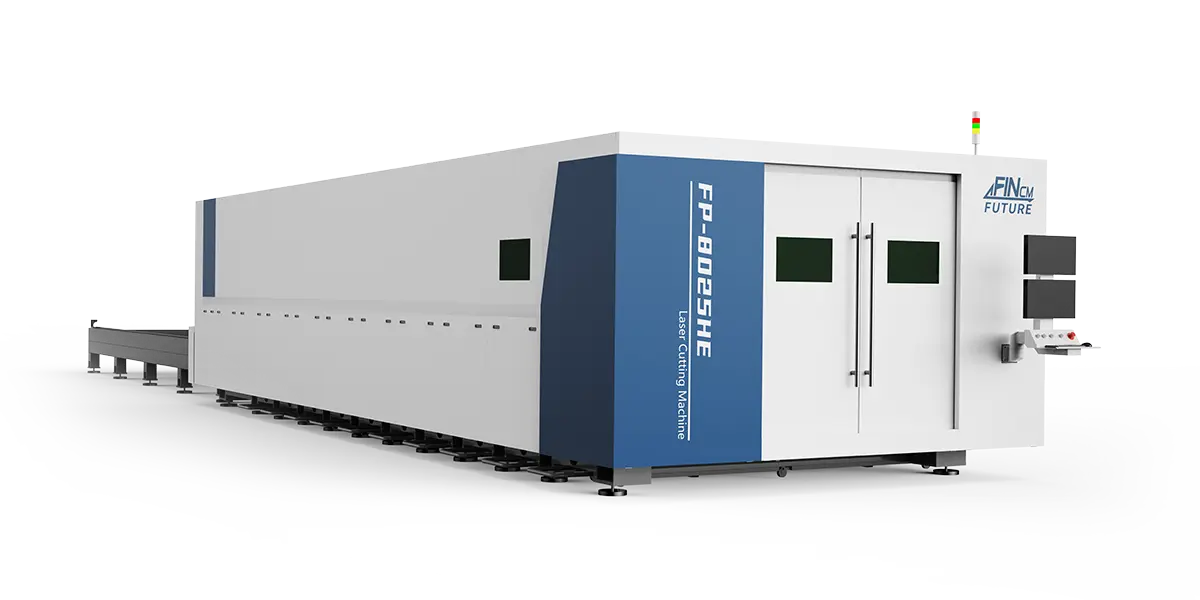

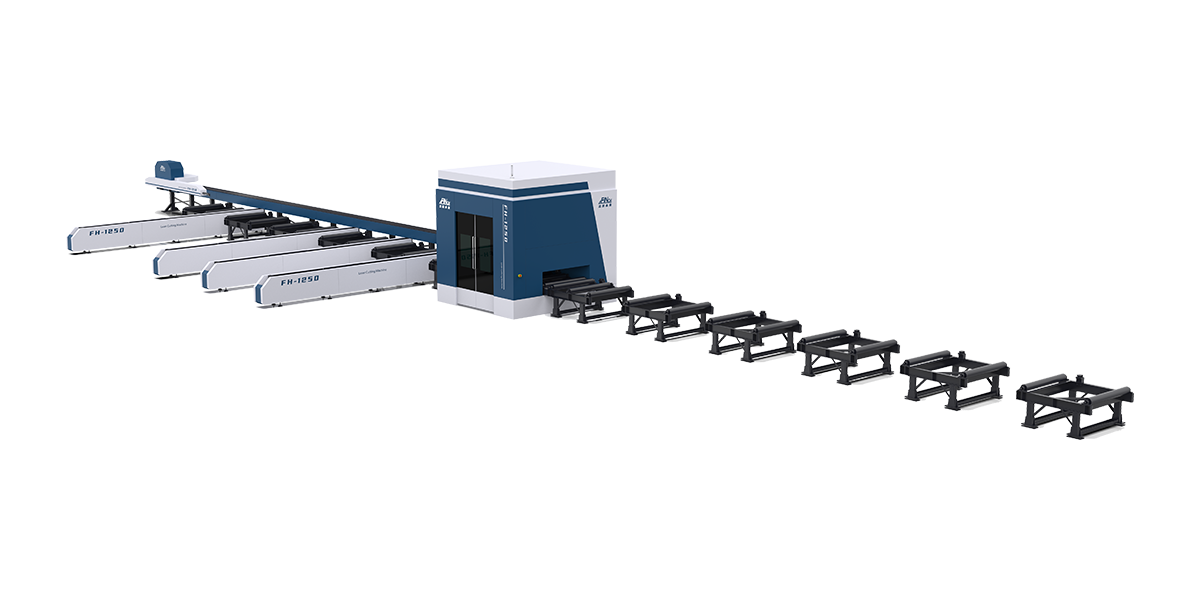

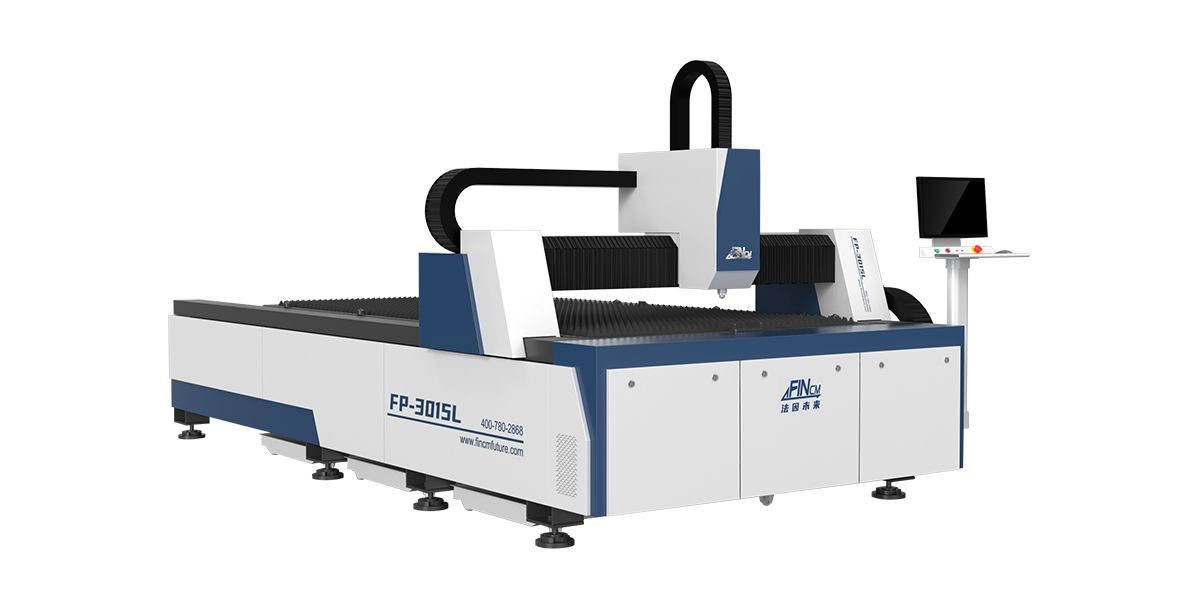

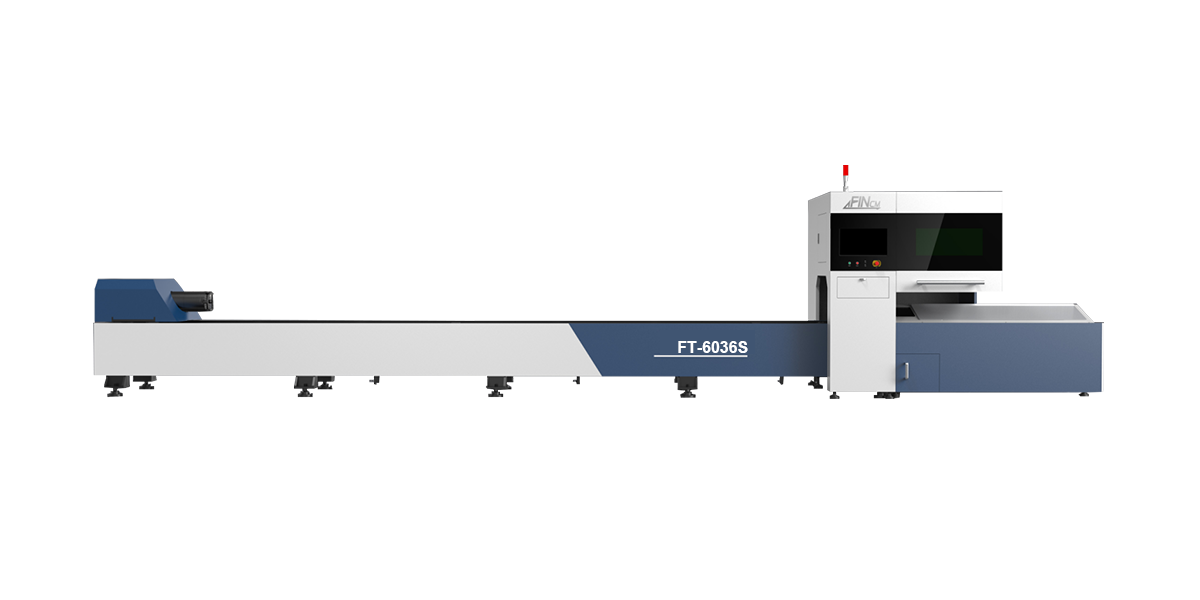

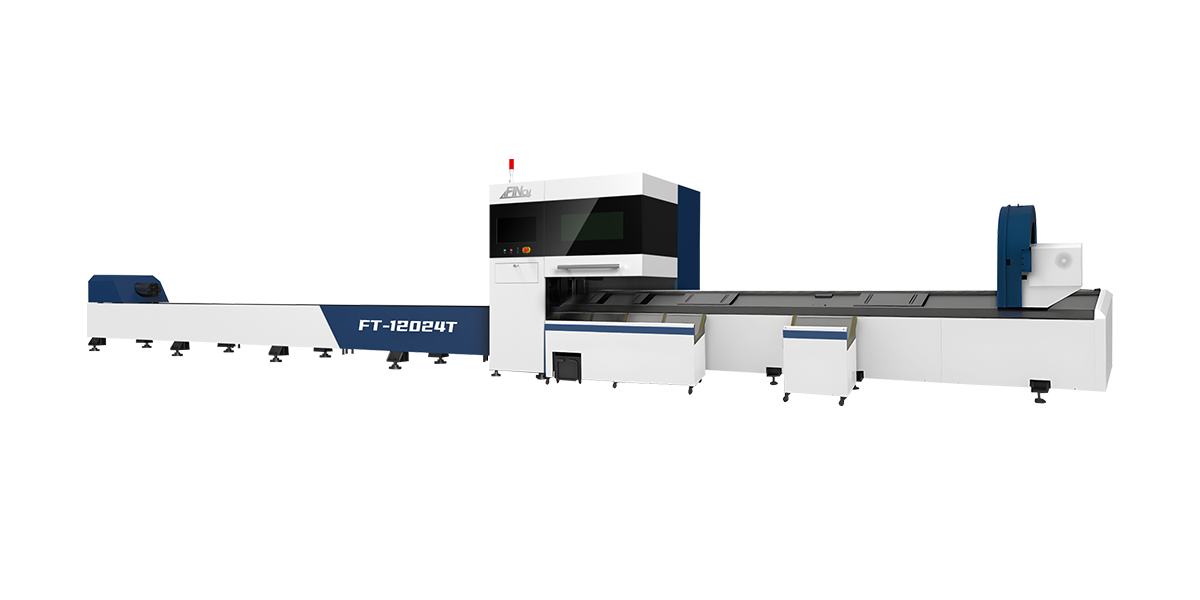

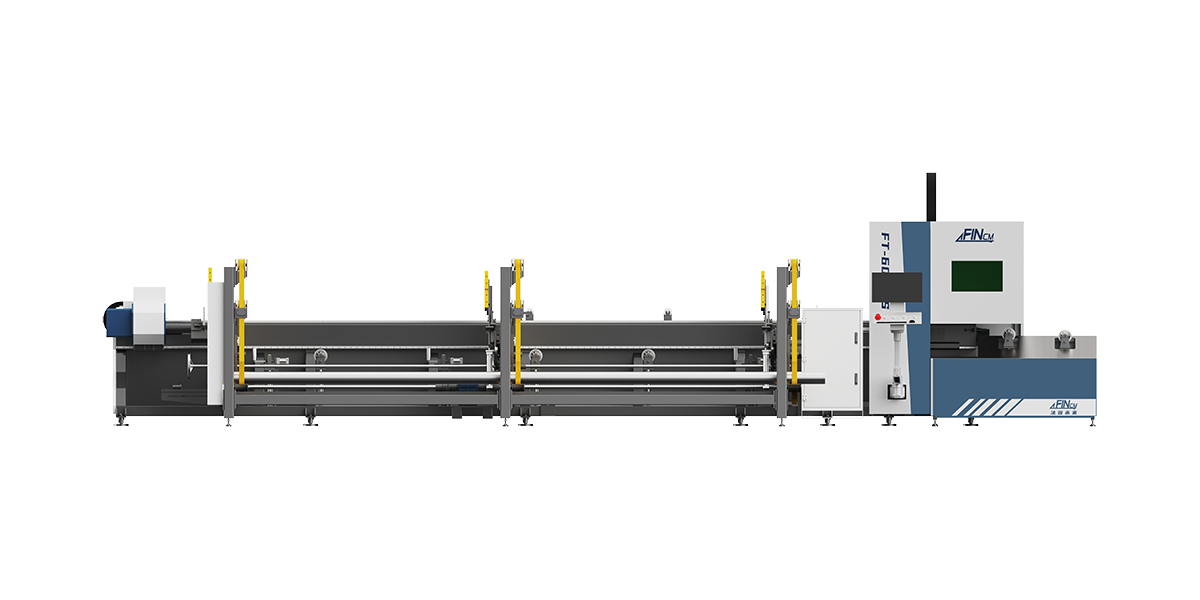

How do I know which cutting machine is best for me, which one should I choose?

What materials are suitable for cutting with the FINCM FUTURE laser cutter?

Why is the laser cutting solution better than other traditional metal processing methods?

How does the choice of gas (e.g., oxygen, nitrogen) used during the cutting process affect the quality of the cuts produced by a laser cutter?

The choice of gas used during the cutting process can affect the quality of the cuts produced by a laser cutter in several ways.

Oxygen is often used as a cutting gas for non-metal materials, such as wood and plastic. When the laser beam hits the material, the oxygen reacts with the material, causing it to burn and creating a clean, precise cut. Oxygen can also help to remove any debris or slag that is produced during the cutting process.

Nitrogen, on the other hand, is commonly used as a cutting gas for metal materials. Nitrogen does not react with the material in the same way as oxygen, but it can help to prevent the material from oxidizing or discoloring during the cutting process. Nitrogen can also help to produce a smoother, more polished edge on the cut material.

In general, the choice of gas will depend on the specific material and application, as well as the desired quality of the cut. Some laser cutters are equipped with multiple gas lines, which allows the operator to switch between different gases as needed.

Support

FINCM FUTURE provides you with 24/7 professional services, as well as diversified support plans and expert services to meet your needs from product use, routine maintenance to optimization and upgrading of the whole cycle, so that you can use FINCM products in this process more efficient and economical!