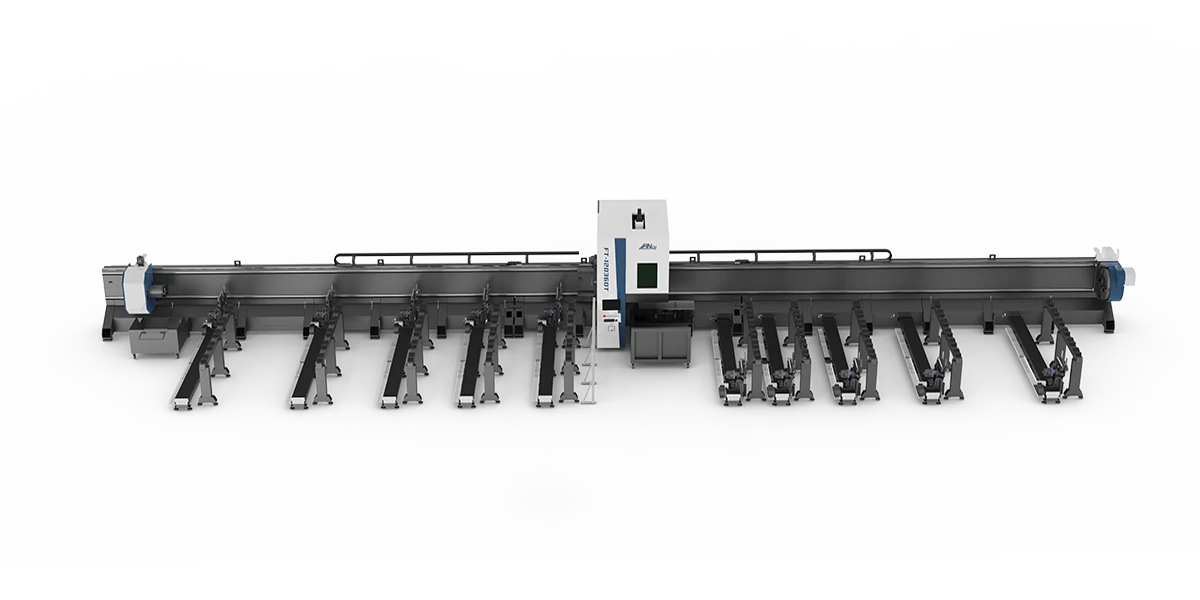

Parameters

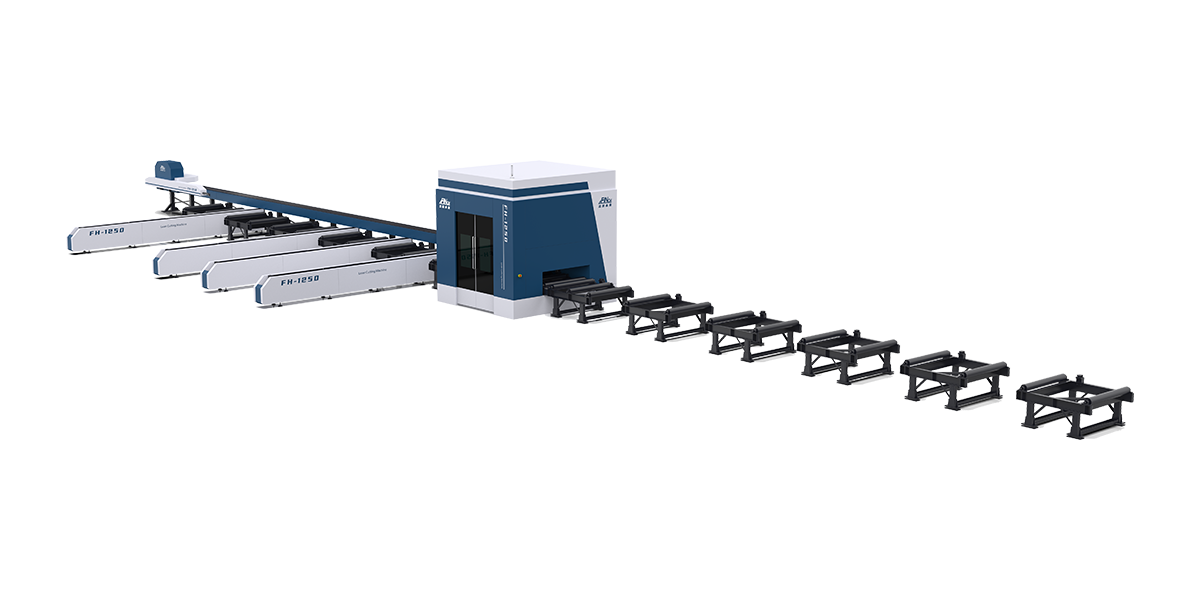

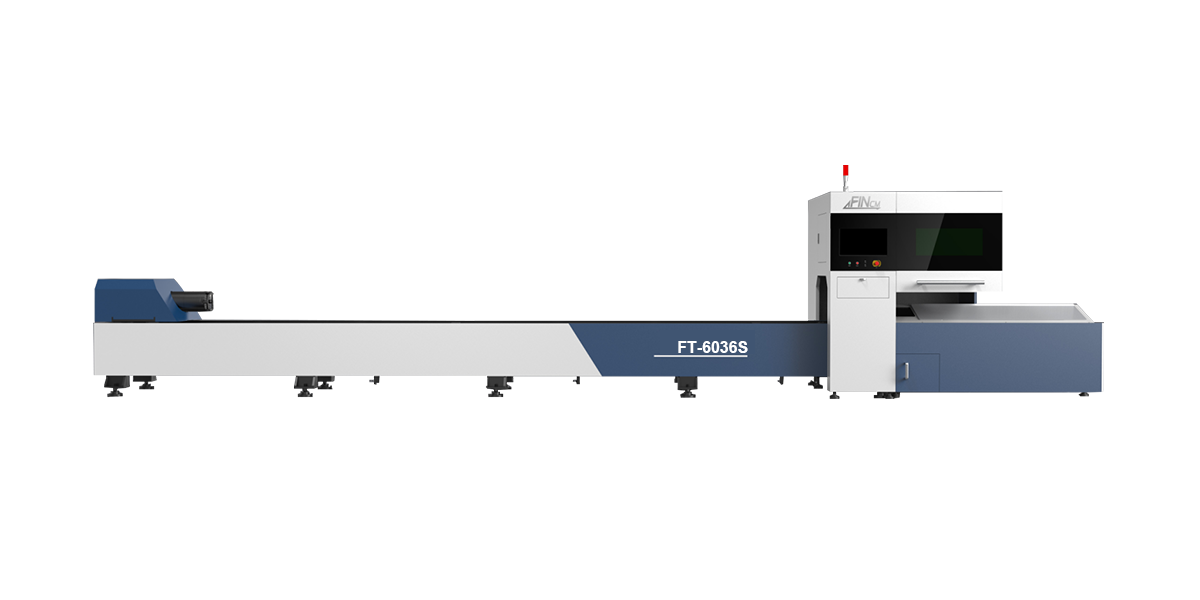

| Model | FT-6012DS | |||

| Pipe type | Round tube/square tube/rectangular tube/oval tube/channel steel/L steel/angle steel | |||

| Pipe processing diameter | Diameter of round pipe | 130mm | ||

| Side length of rectangular tube | 8x8mm-120x120mm | |||

| Chuck maximum attached middle school | 100Kg | |||

| Max. rotation speed of chuck | 190r/min | |||

| Maximum acceleration | 1.5G | |||

| X/Y Axis positioning accuracy | 0.05mm/m | |||

| Automatic feeding range | round tube/square tube/rectangular tube | 4000mm-6200mm | ||

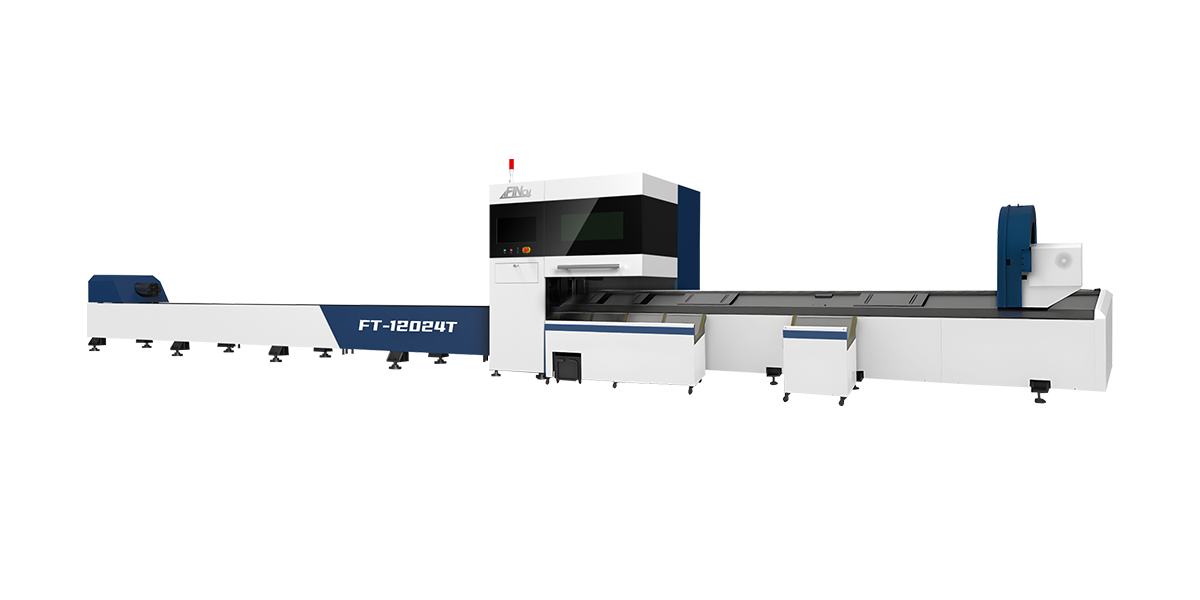

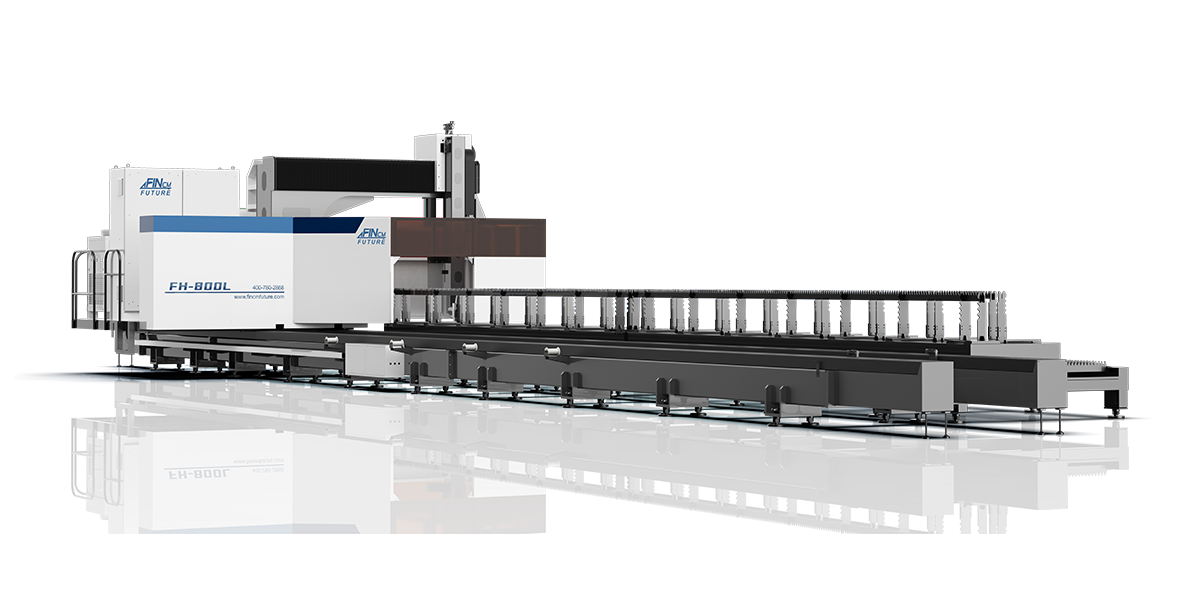

Heavy plate welded bed

Lean efficient solid and reliable:Full plate welding design, high mechanical strength, high temperature resistance, not easy to deformation, the overall structure rigidity of the bed is improved, and the deformation effect caused by heat or impact is reduced.

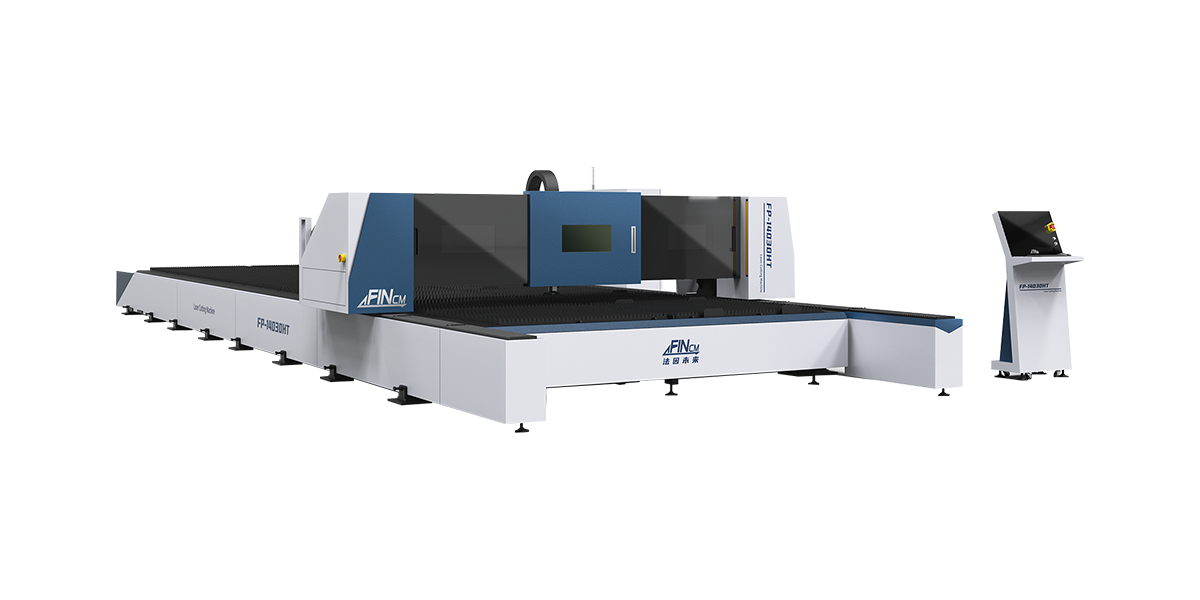

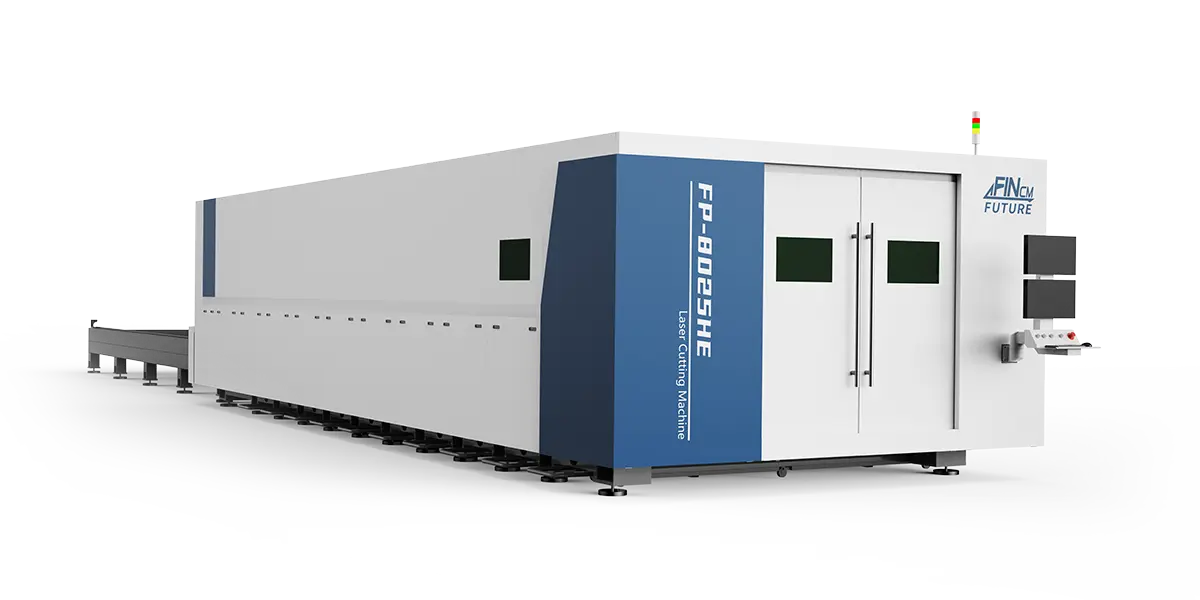

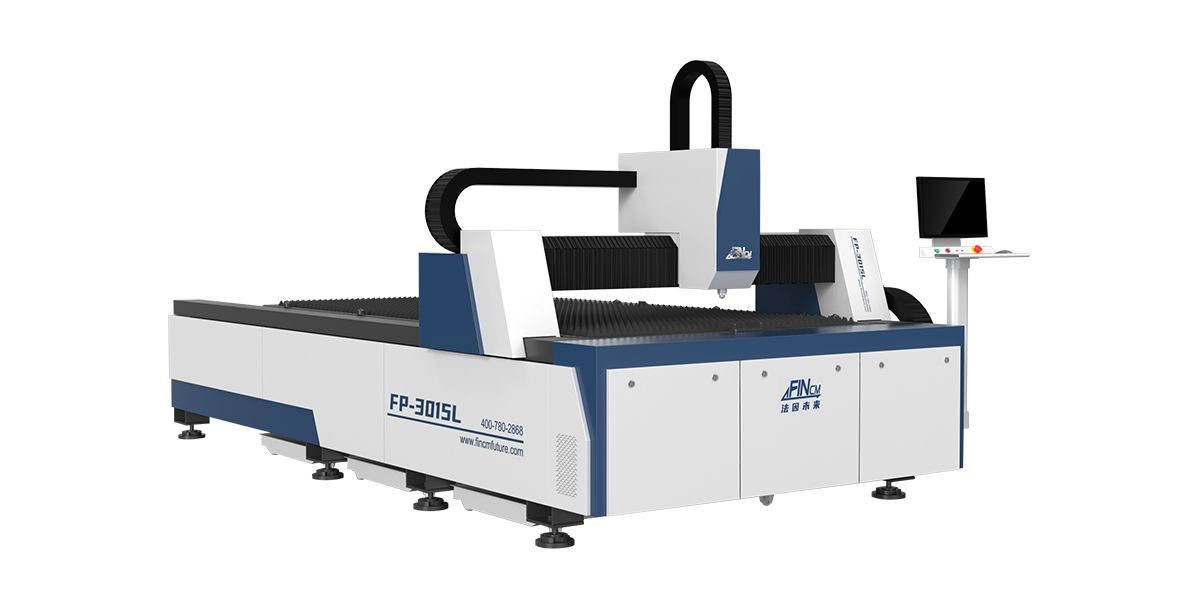

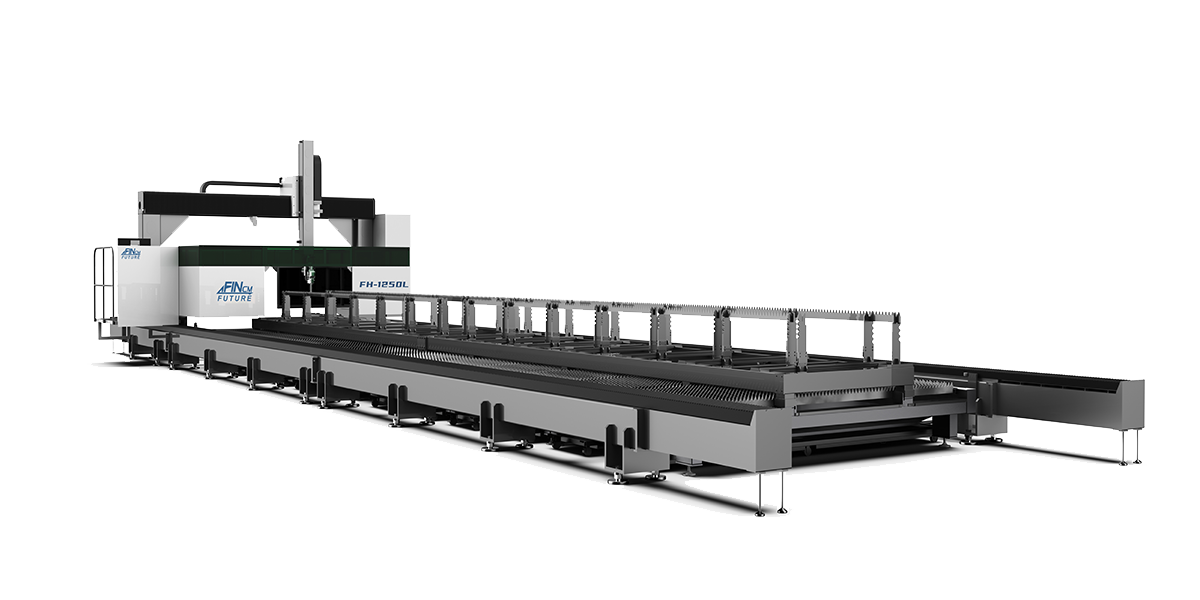

Large-format plate thick cutting

Processing format8000*2500mm

The whole board is thick cut, which greatly improves the material utilization rate, brings faster processing experience, shortens your delivery time, and multiplies the efficiency.

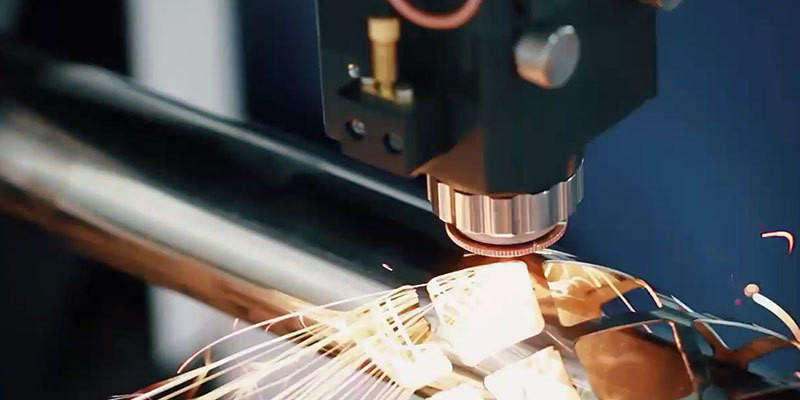

Groove laser cutting system

It has the characteristics of stable and reliable, simple operation, convenient expansion and strong anti-interference.

Maximum acceleration:2.0G

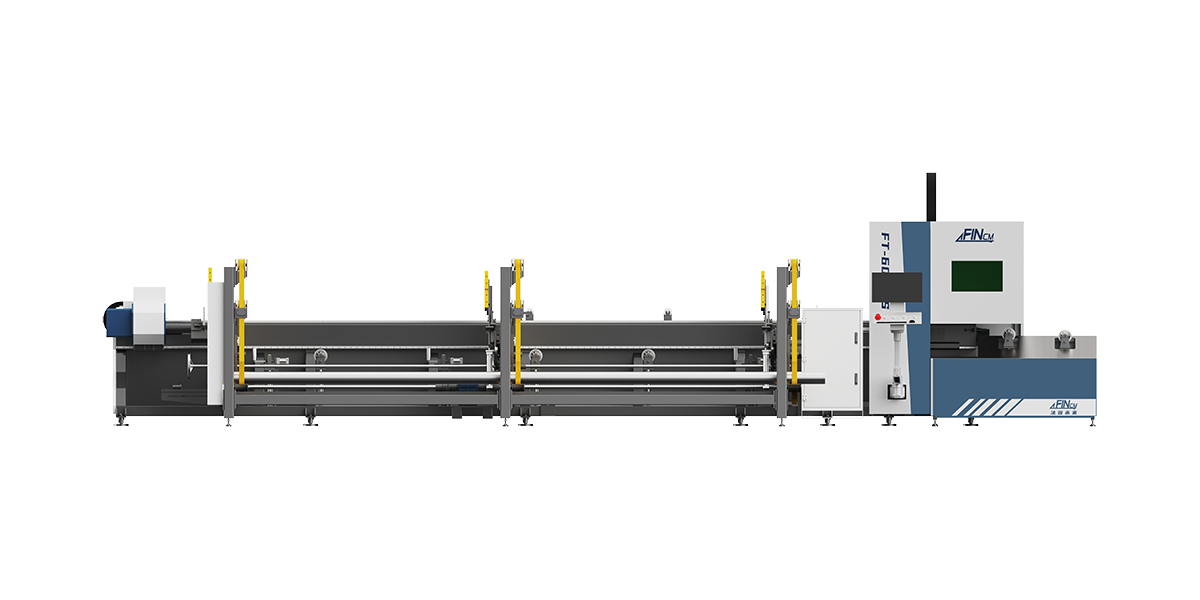

high precision transmission system

Selection of high-precision reducer, precision linear guide, high-precision rack, ball screwThe high quality parts build a complete set of high-precision transmission system, with good performance, extremely low failure rate and long service life, ensuring better long-term and stable operation of the equipment.

Sixth generation aviation aluminum beam

The beam adopts lightweight design, which gives full play to the high dynamic performance of the equipment, good toughness and ductility, high light weight, light weight, improved processing efficiency, and more durable.

intelligent bus system

Intelligent path optimization, convenient debugging, stable and reliable. Perforated slag removal, dual-drive torque protection, multi-plate edge inspection, air pressure DA correction, greatly improving cutting efficiency.

segmented matrix ventilation

The bed segmented smoke exhaust device has double rows and multiple rows of high-sealing partitions, 360 ° strong adsorption, adaptive control, and filters out harmful gases, smoke and dust, etc.

Samples

Tube cut fincm

Tube cut fincm

Tube cut fincm

Tube cutter

Submit your information for a customized solution

Filling in your phone and email information will help us get in touch with you in a timely manner and solve your problem as soon as possible.

Support

FINCM FUTURE provides you with 24/7 professional services, as well as diversified support plans and expert services to meet your needs from product use, routine maintenance to optimization and upgrading of the whole cycle, so that you can use FINCM FUTURE products in this process more efficient and economical!