Comparison and selection of laser cutting machine and other cutting technology

Release time:

2023-11-15

Author:

Source:

In the manufacturing industry, cutting is one of the important production links. In addition to the traditional cutting technology, with the continuous development of science and technology, laser cutting technology has also been widely used. When choosing a cutting technology, many factors need to be considered, such as cutting accuracy, speed, cost, material type, etc. This article will compare the advantages and disadvantages of laser cutting machines with other cutting technologies to help you make the right choice.

In the manufacturing industry, cutting is one of the important production links. In addition to the traditional cutting technology, with the continuous development of science and technology, laser cutting technology has also been widely used. When choosing a cutting technology, many factors need to be considered, such as cutting accuracy, speed, cost, material type, etc. This article will compare the advantages and disadvantages of laser cutting machines with other cutting technologies to help you make the right choice.

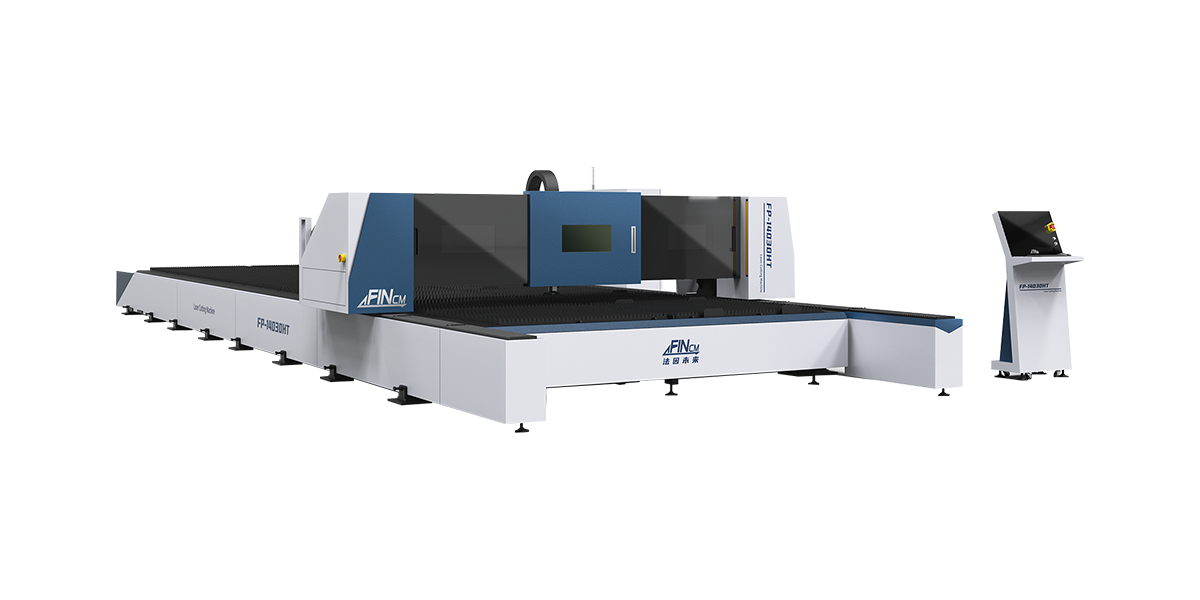

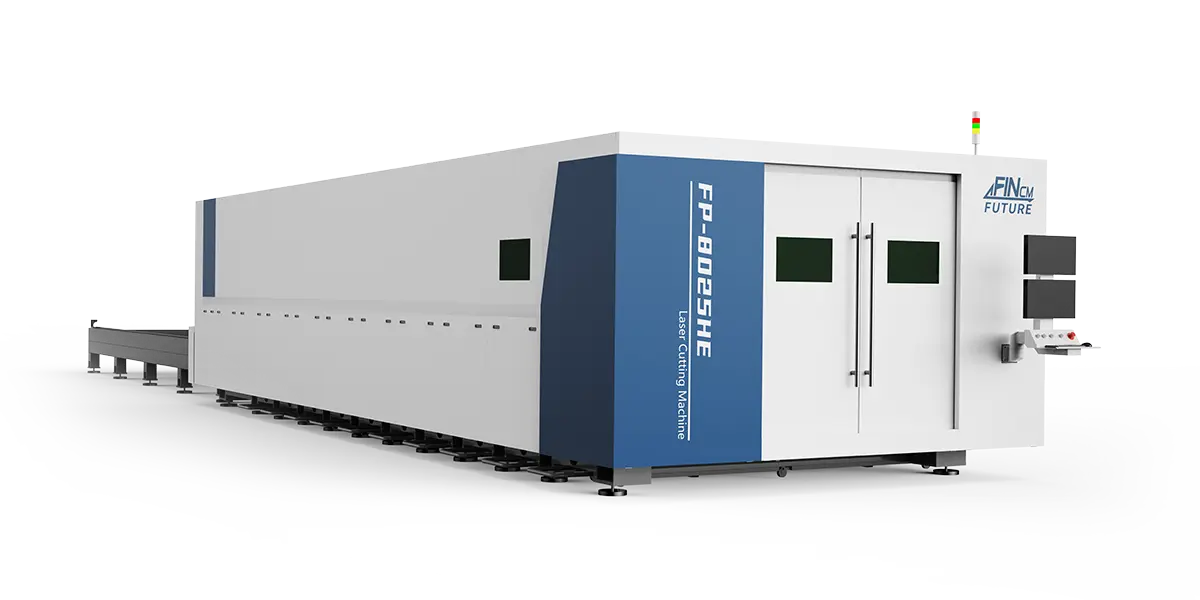

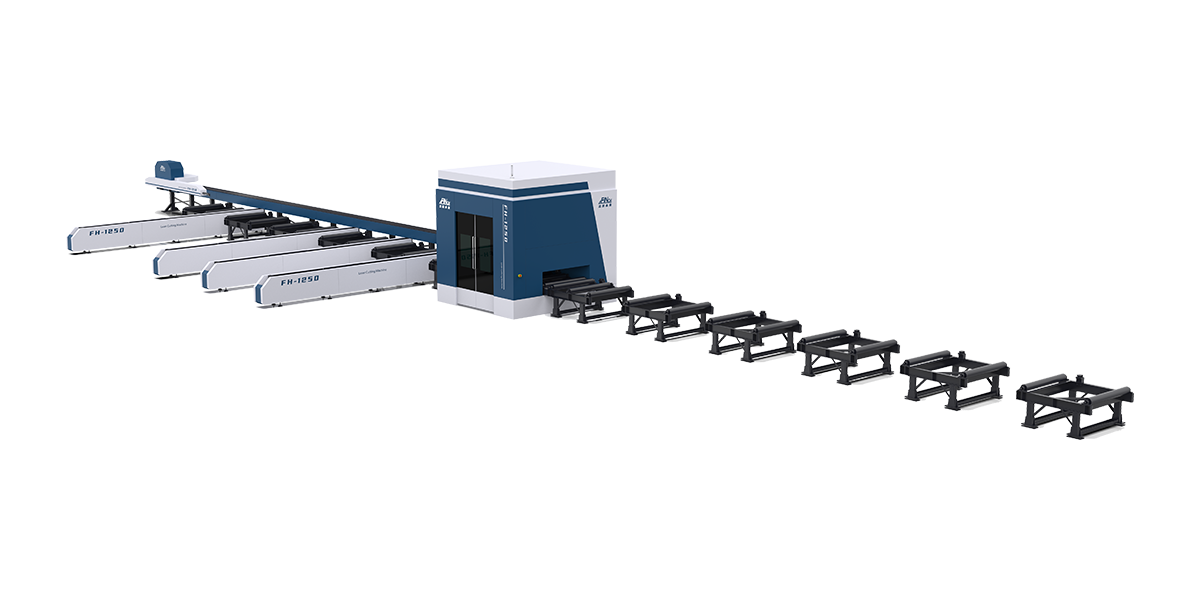

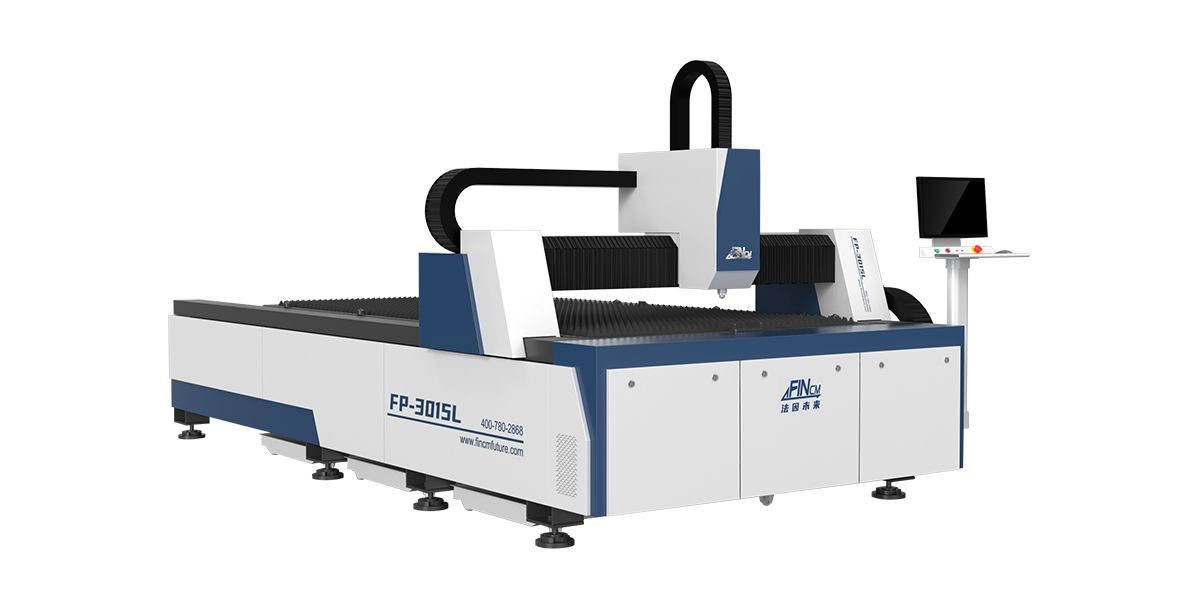

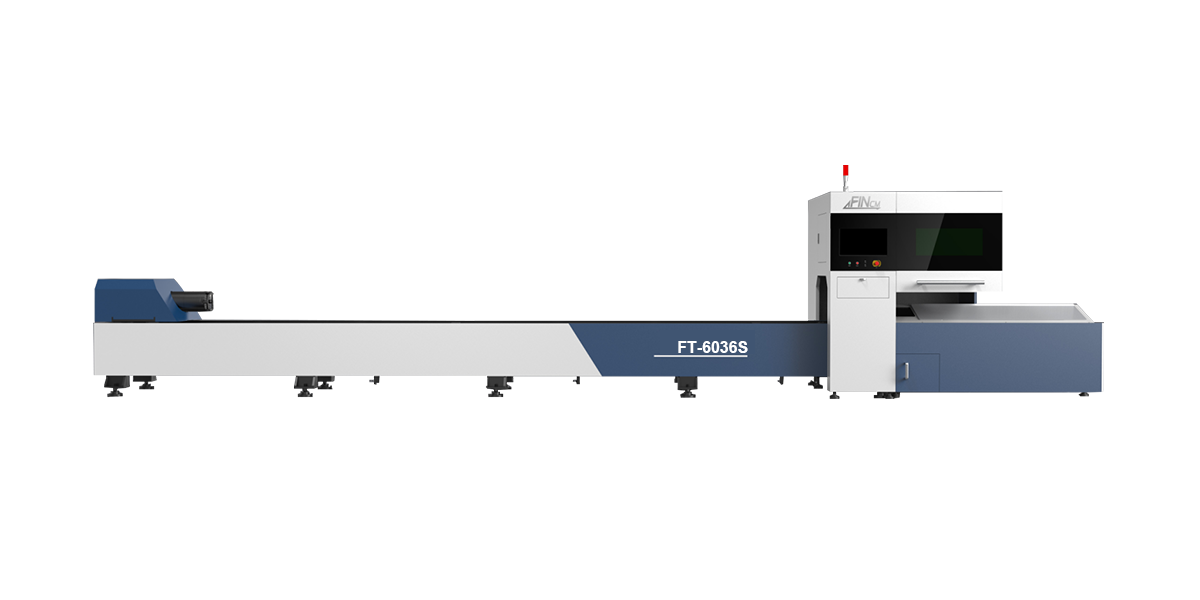

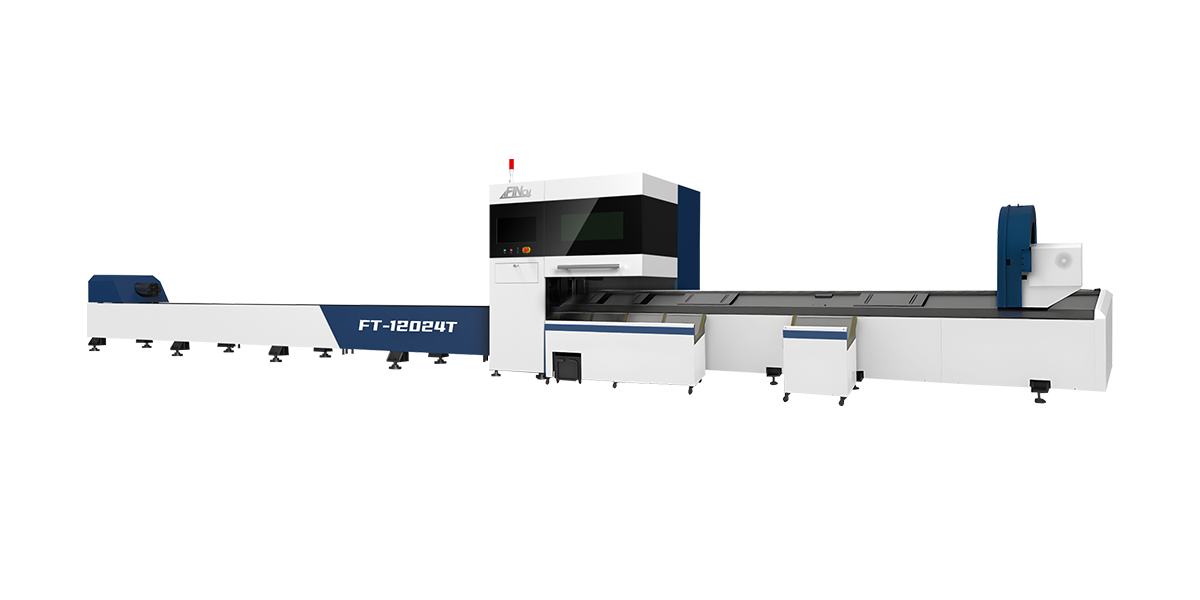

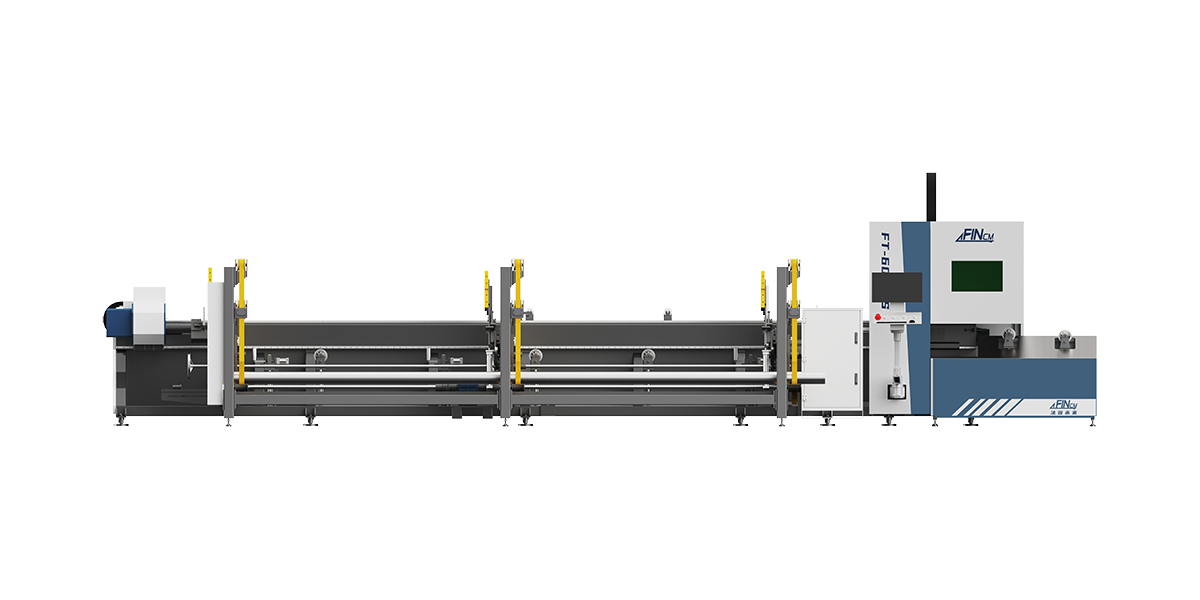

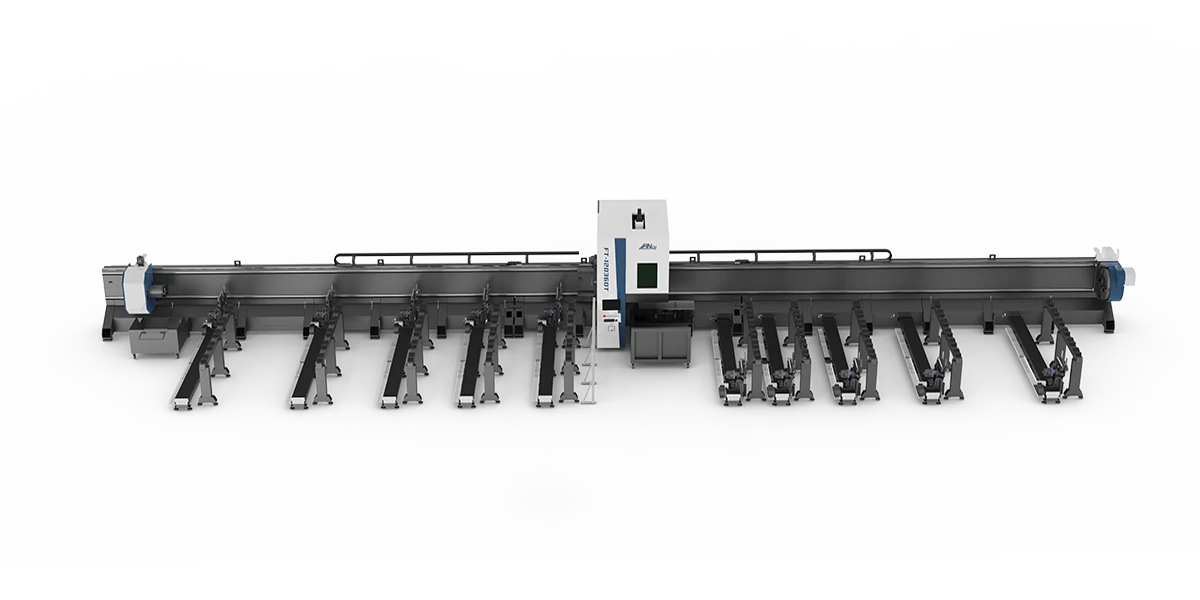

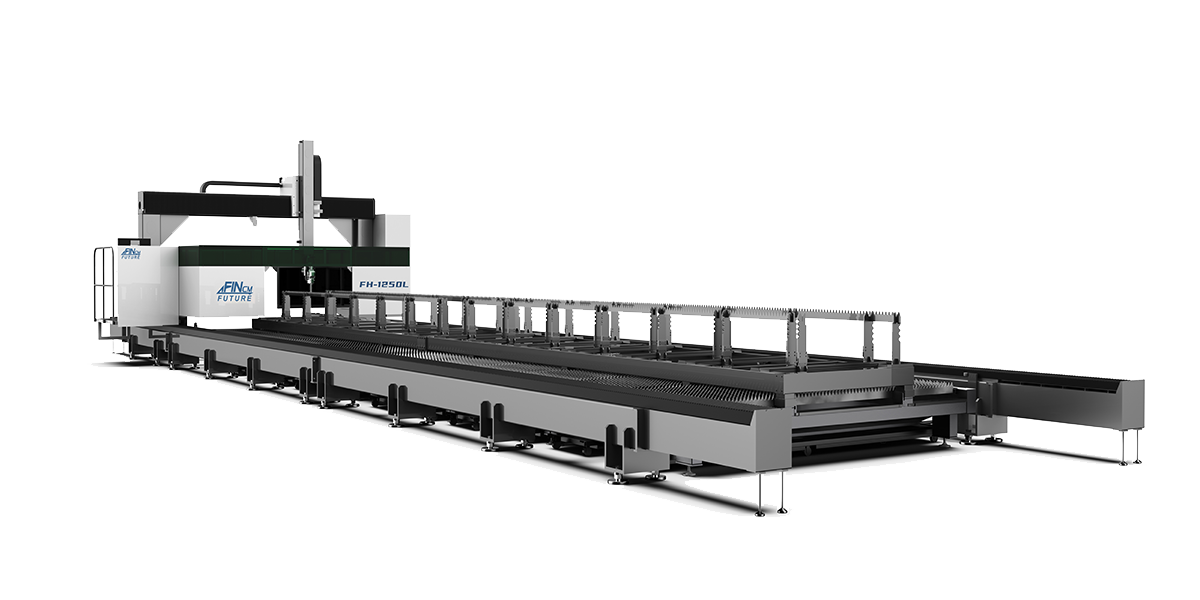

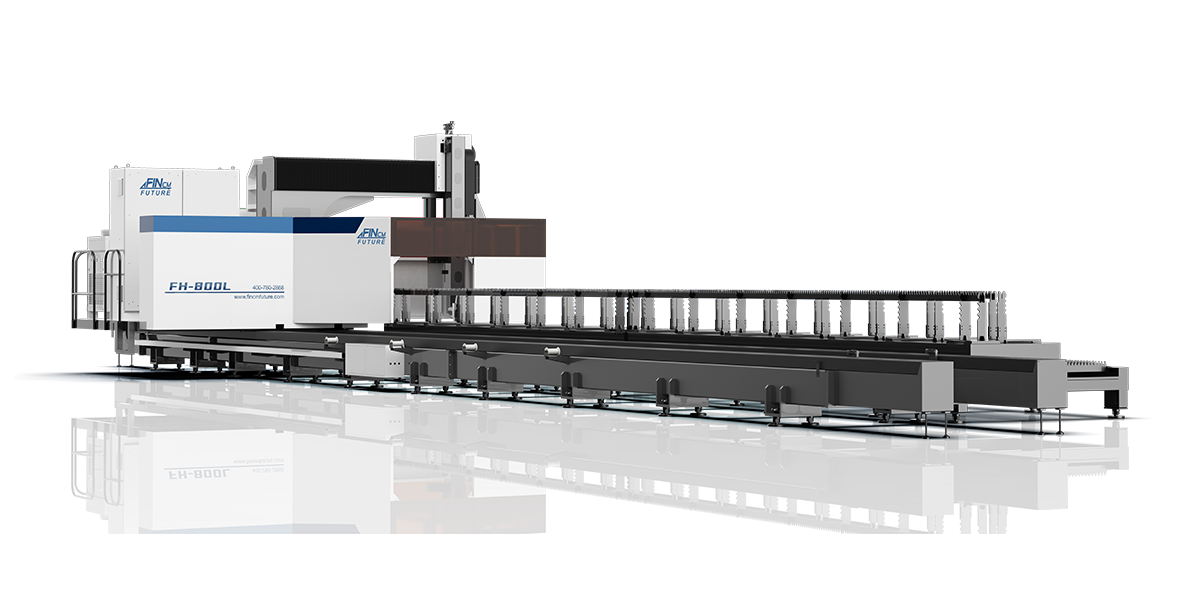

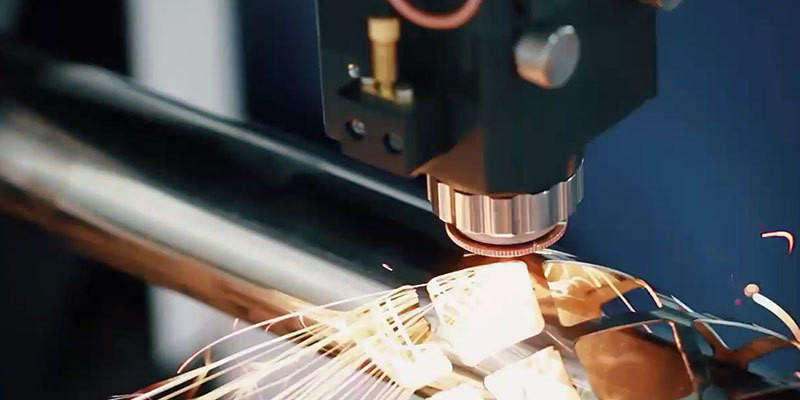

Comparison of 1. laser cutting machine with other cutting technologies Flame cutting is a traditional cutting technology that cuts materials by burning flames. The advantages of this method are low cost and simple operation, and can be used for cutting thick plates. However, the precision of flame cutting is low, the speed is slow, and the heat affected area of the material is large, which is easy to cause material deformation and oxidation. Plasma cutting Plasma cutting is a commonly used modern cutting technology that cuts materials through the energy of high-temperature plasma. The advantage of this method is that it is suitable for cutting various metal materials, with high speed and high precision. However, the quality of plasma cutting is not as good as laser cutting, and the cost is higher, and the cutting ability of thin plates and slits is limited. Waterjet cutting Waterjet cutting is a technology that uses high-pressure water flow to cut materials. The advantage of this method is that it is suitable for various materials, including metals, non-metals, composite materials, etc. The waterjet has high cutting accuracy and good cutting quality, but the cost is high and the cutting speed is slow. Laser cutting Laser cutting is a cutting technology that uses a high-energy laser beam to irradiate the surface of a material to melt, vaporize or reach the ignition point, and at the same time blow away the melted or burned material with a high-speed airflow. The advantages of laser cutting are high precision, fast speed, and good cut quality. It is suitable for cutting various metal and non-metal materials. At the same time, the width and depth of laser cutting can be precisely controlled, which is suitable for cutting various complex shapes and patterns. However, the cost of laser cutting is higher, and the professional quality of the operator is higher.

2. laser cutting machine selection considerations Material type: Different cutting techniques are suitable for different material types. For the cutting of metal materials, laser cutting has high precision and speed, and the cutting quality is good; for the cutting of non-metallic materials and composite materials, water jet cutting has a good effect. Cutting accuracy: The accuracy of different cutting technologies is different. The accuracy of laser cutting is high, which can reach the micron level; the accuracy of flame cutting and plasma cutting is low, which is suitable for rough machining. Cutting speed: laser cutting speed is fast, can quickly complete the cutting of large areas; and flame cutting and plasma cutting speed is slow, suitable for small area and complex shape cutting. Cost: The cost of equipment and consumables required for different cutting technologies varies. The cost of equipment and consumables for laser cutting is higher, but the service life is long; the cost of equipment for flame cutting and plasma cutting is lower, but the cost of consumables is higher. Quality of operators: Laser cutting requires operators to have high professional quality and technical level; while the operation of flame cutting and plasma cutting is relatively simple, and the professional quality of operators is low.

In summary, when choosing a laser cutting machine or other cutting technology, it is necessary to comprehensively consider factors such as material type, accuracy, speed, cost, and operator quality. According to the actual production demand and processing characteristics, choosing the most suitable cutting technology is the key to ensure production efficiency and cost control.

Key words:

Latest developments

Support

FINCM FUTURE provides you with 24/7 professional services, as well as diversified support plans and expert services to meet your needs from product use, routine maintenance to optimization and upgrading of the whole cycle, so that you can use FINCM products in this process more efficient and economical!