How to improve production efficiency and reduce costs through laser cutting machine

Release time:

2023-11-15

Author:

Source:

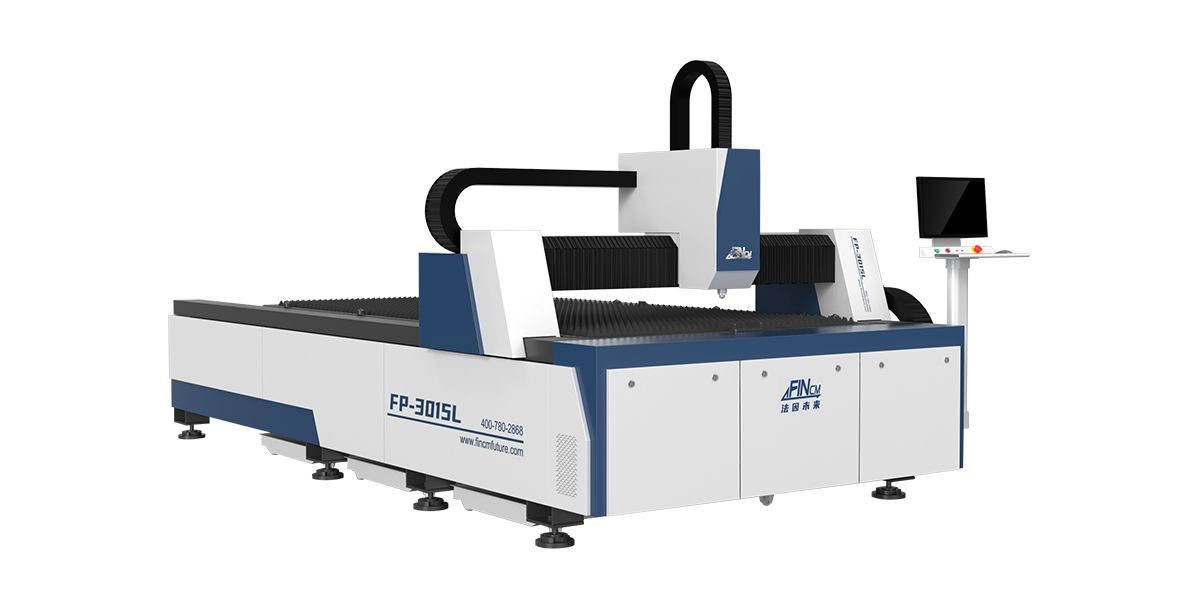

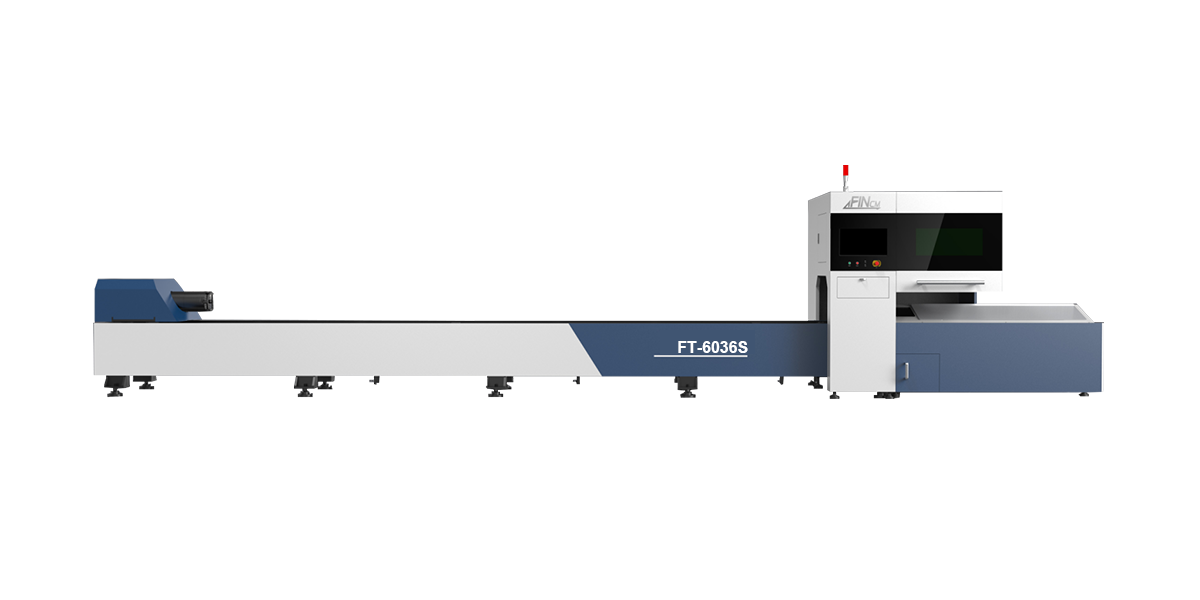

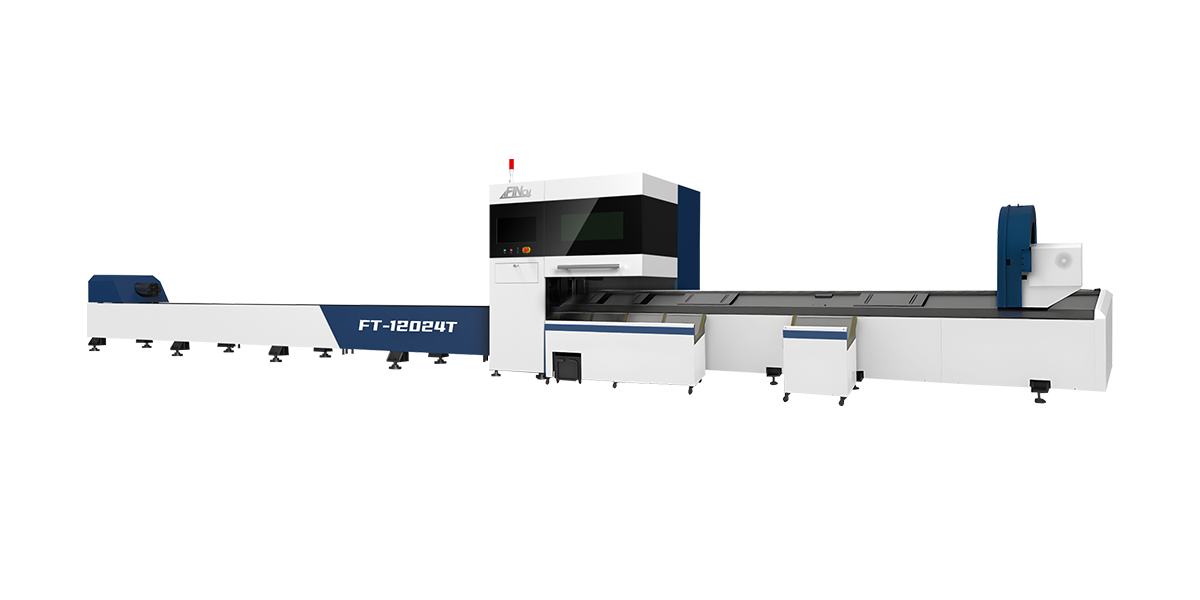

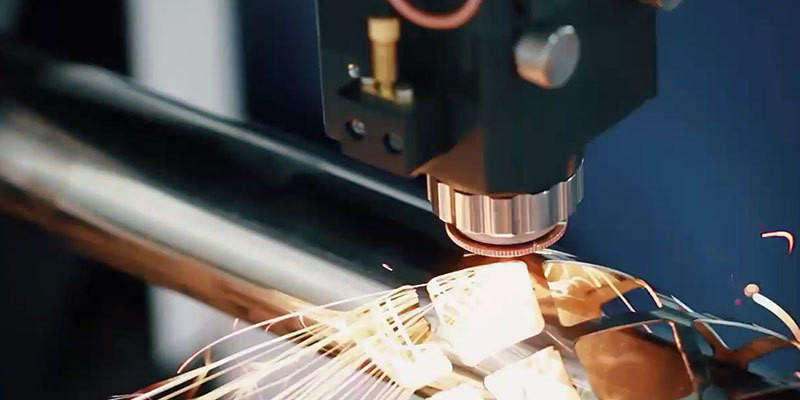

In the manufacturing industry, laser cutting machine, as a high-precision, high-speed and high-efficiency processing equipment, has become an important tool to improve production efficiency and reduce costs. The following will introduce how to improve production efficiency and reduce costs through laser cutting machines.

In the manufacturing industry, laser cutting machine, as a high-precision, high-speed and high-efficiency processing equipment, has become an important tool to improve production efficiency and reduce costs. The following will introduce how to improve production efficiency and reduce costs through laser cutting machines.

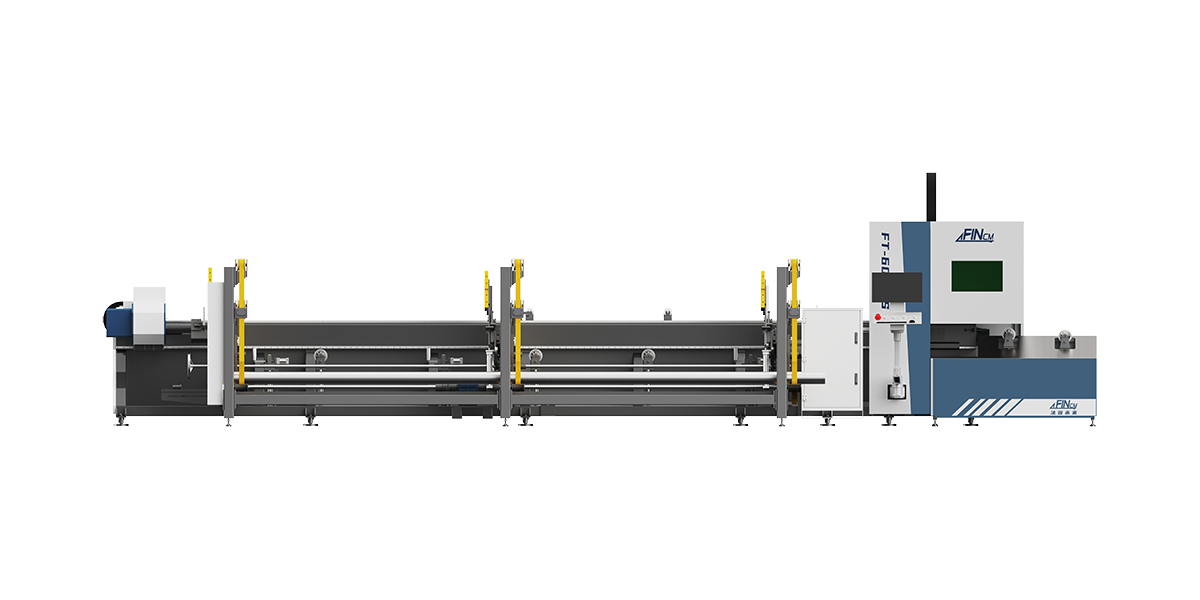

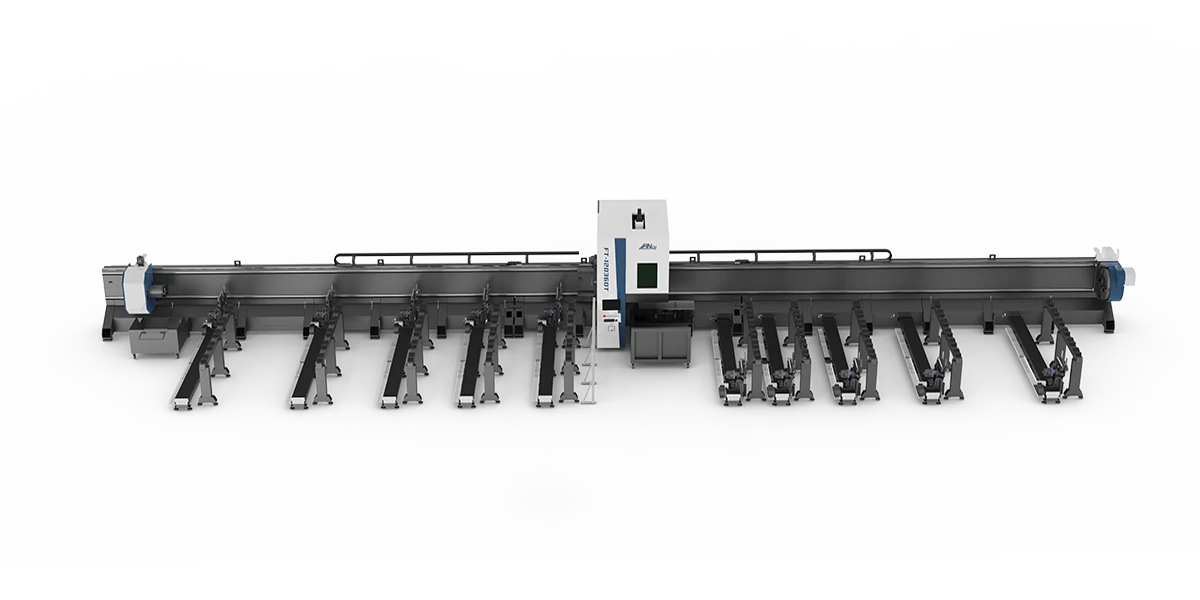

1. optimizing the cutting process to develop a reasonable cutting plan In the use of laser cutting machine, it is necessary to develop a reasonable cutting plan, including the optimization of cutting sequence, path, speed and other parameters. Reasonable cutting scheme can effectively improve production efficiency, reduce energy consumption and tool loss. The introduction of automated operation can reduce manual intervention and improve the stability and efficiency of the production process. By writing programs and introducing robots, automatic loading and unloading, cutting, cleaning and other operations can be realized to improve production efficiency. Introducing the production management system By introducing the production management system, the comprehensive monitoring and management of the production process can be realized, the production plan and inventory management can be optimized, and the production efficiency and cost control ability can be improved.

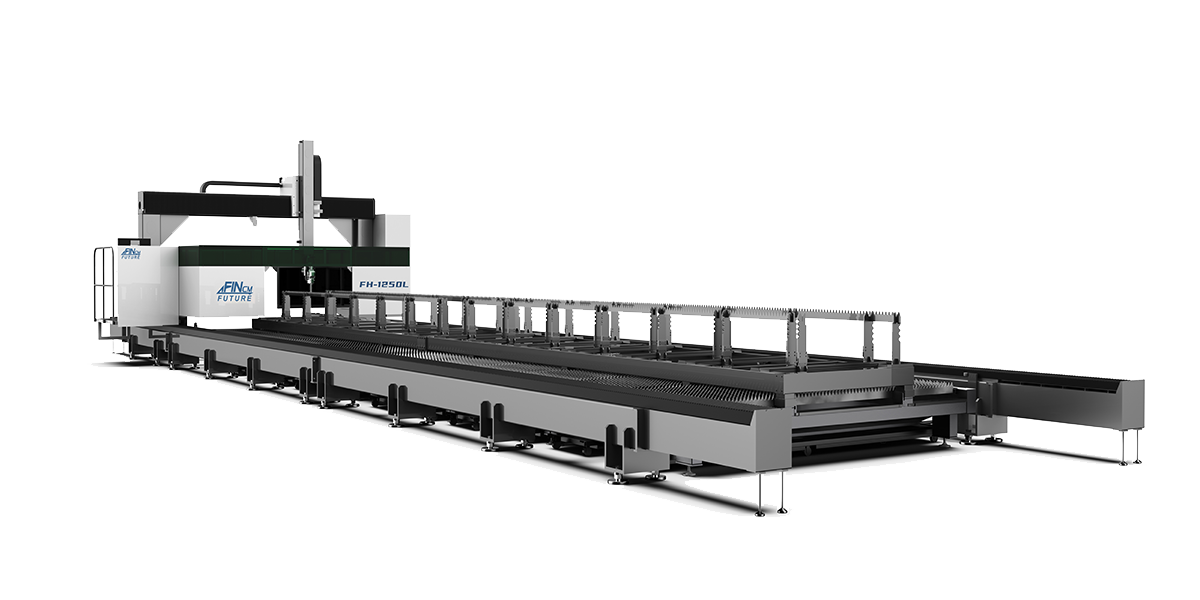

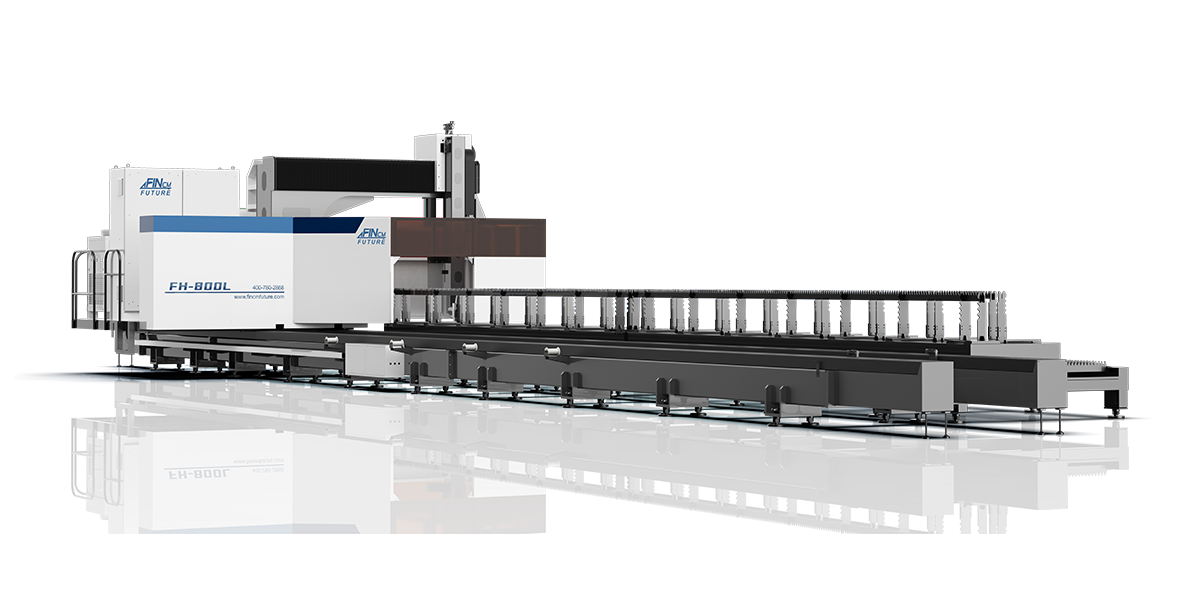

2. improve the accuracy and stability of equipment selection of high-precision equipment selection of high-precision, high-quality laser cutting machine, can improve the cutting accuracy and stability of the equipment, reduce the error and failure rate, improve production efficiency. Regular maintenance and maintenance Regular maintenance and maintenance of the laser cutting machine can maintain the accuracy and stability of the equipment, extend the service life of the equipment, and reduce maintenance costs. Using high-quality tools and consumables Using high-quality tools and consumables can improve cutting quality and efficiency, and reduce the time and cost of changing tools and adjusting parameters.

3. Application of Intelligent Technology Introducing Internet of Things Technology By introducing Internet of Things technology, remote monitoring and management of laser cutting machines can be realized, the operating status and production data of the equipment can be mastered, problems can be found and solved in time, and production efficiency can be improved. Application of artificial intelligence technology The application of artificial intelligence technology can achieve equipment failure prediction, production optimization and other goals through data analysis and model building. Through the analysis of historical data by artificial intelligence technology, it is possible to predict possible equipment failures and carry out repairs and maintenance in advance to avoid production interruptions and equipment damage. At the same time, artificial intelligence technology can also analyze production data in real time, find bottlenecks and problems in the production process, put forward optimization suggestions, and further improve production efficiency.

In summary, by optimizing the cutting process, improving the accuracy and stability of the equipment, and applying intelligent technology, the production efficiency of the laser cutting machine can be effectively improved and the cost can be reduced. For the manufacturing industry, the implementation of these measures can not only improve the competitiveness of enterprises, but also create greater economic and social benefits for enterprises.

Key words:

Latest developments

Support

FINCM FUTURE provides you with 24/7 professional services, as well as diversified support plans and expert services to meet your needs from product use, routine maintenance to optimization and upgrading of the whole cycle, so that you can use FINCM products in this process more efficient and economical!