Application and advantages of laser cutting machine in electronic industry

Release time:

2023-11-15

Author:

Source:

The electronics industry is an industry that continues to innovate and develop. As an advanced processing equipment, laser cutting machines have been widely used in this industry. With its high precision, high speed and high efficiency, laser cutting machine has brought revolutionary changes to the production and processing of the electronics industry. This article will introduce the application and advantages of laser cutting machine in the electronics industry to help you better understand the application of laser cutting machine in the electronics industry.

The electronics industry is an industry that continues to innovate and develop. As an advanced processing equipment, laser cutting machines have been widely used in this industry. With its high precision, high speed and high efficiency, laser cutting machine has brought revolutionary changes to the production and processing of the electronics industry. This article will introduce the application and advantages of laser cutting machine in the electronics industry to help you better understand the application of laser cutting machine in the electronics industry.

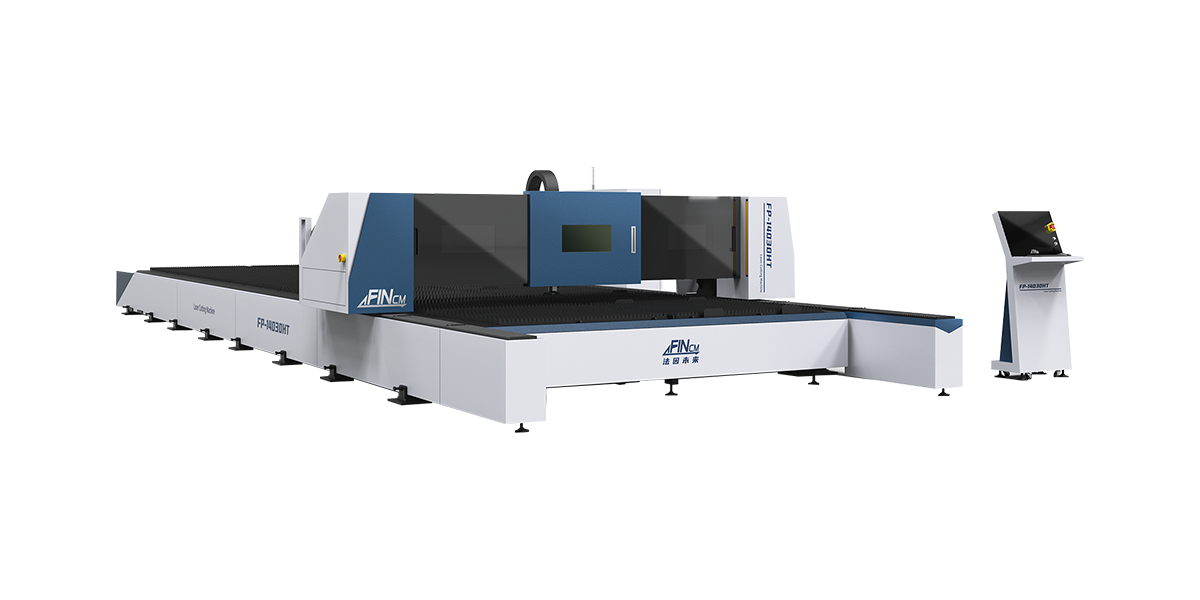

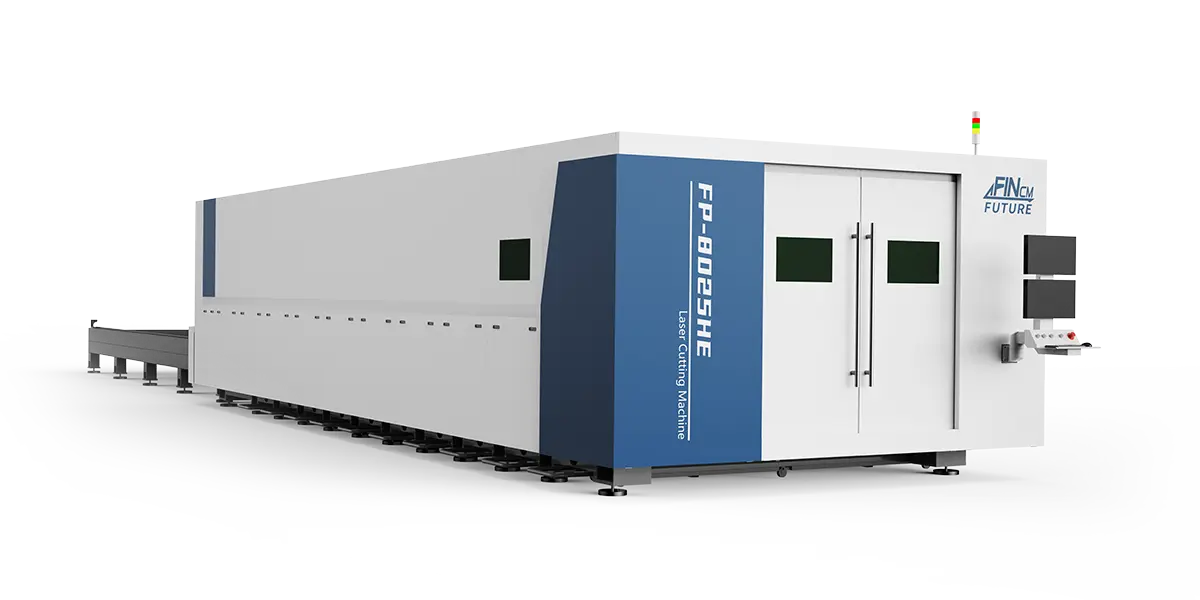

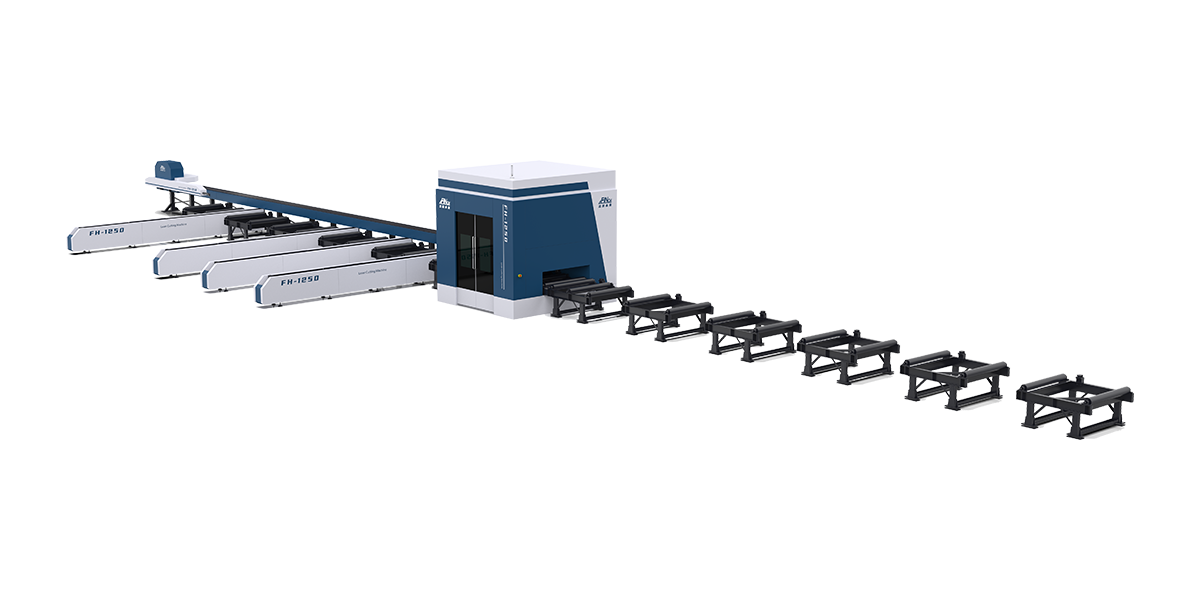

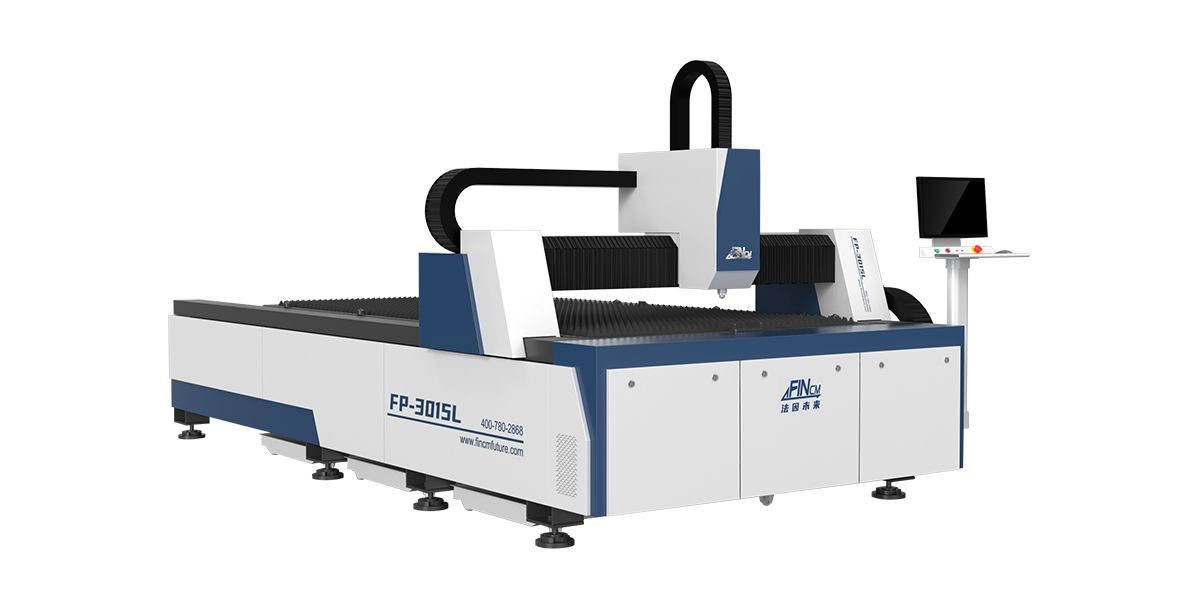

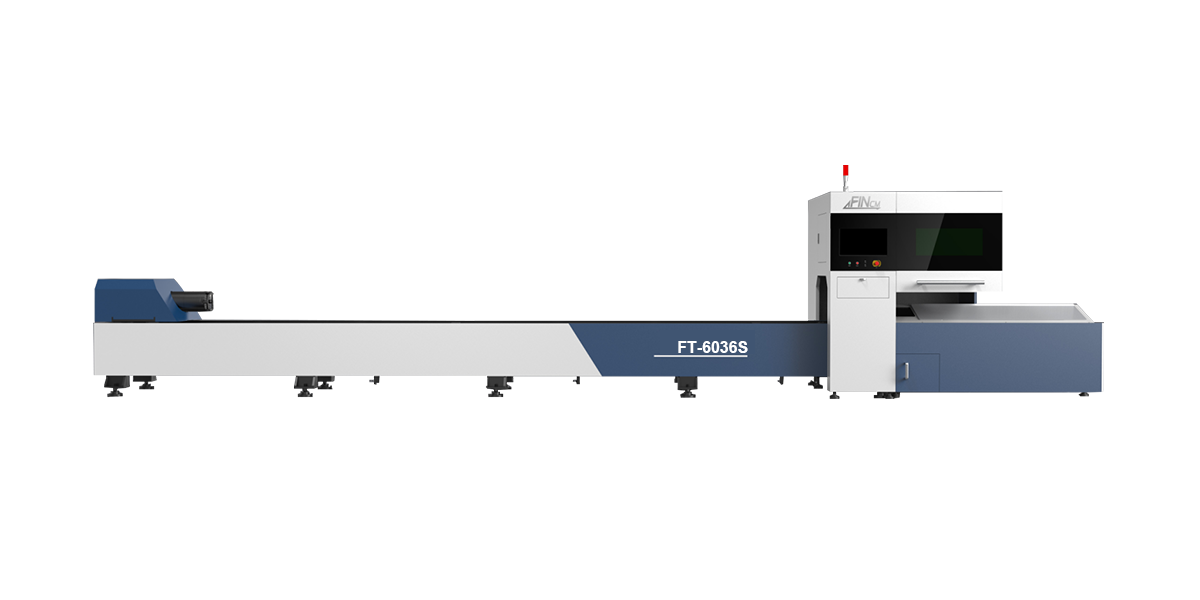

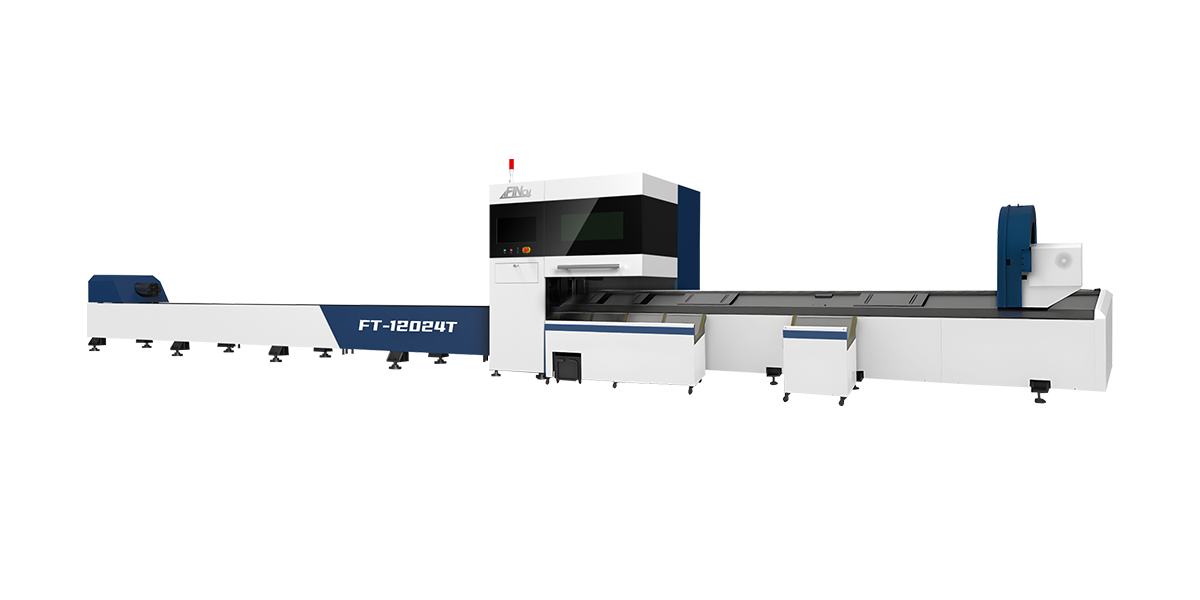

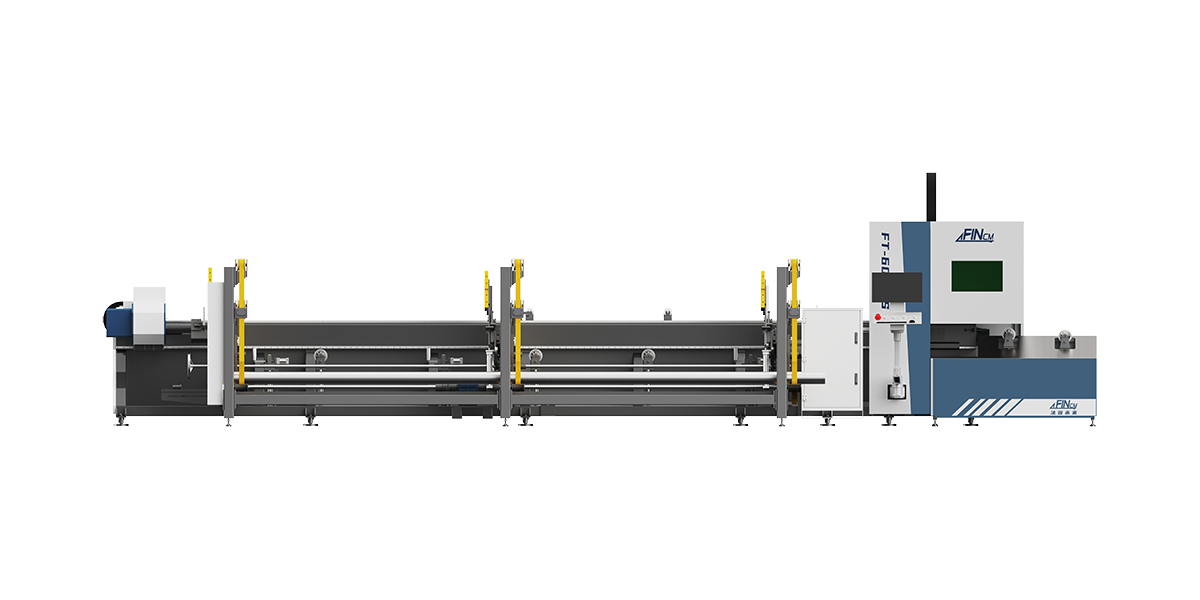

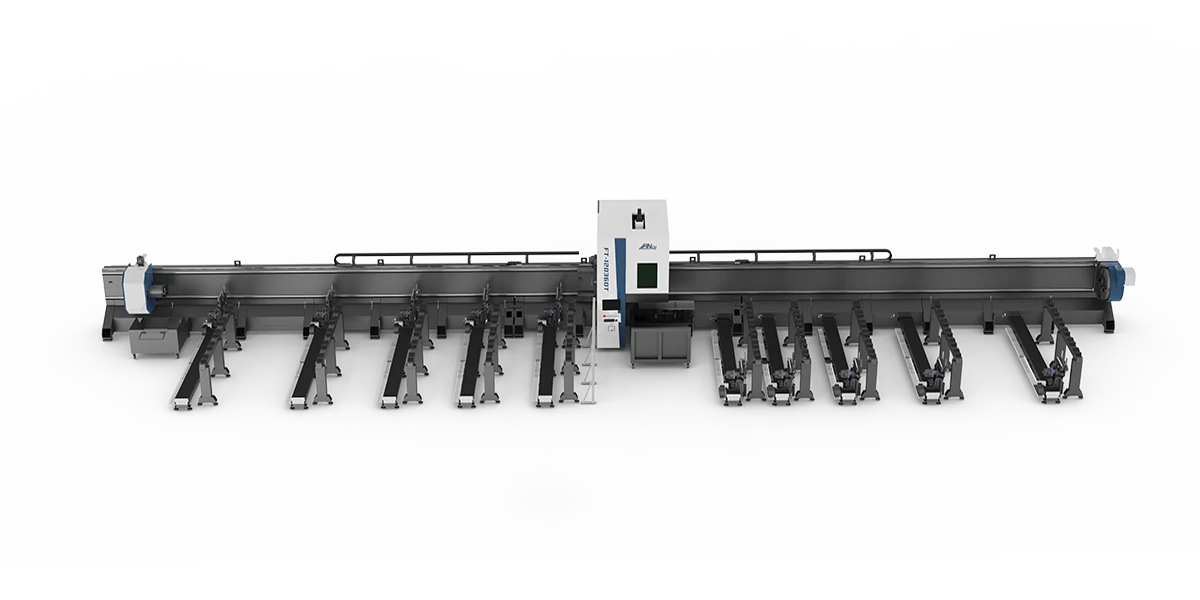

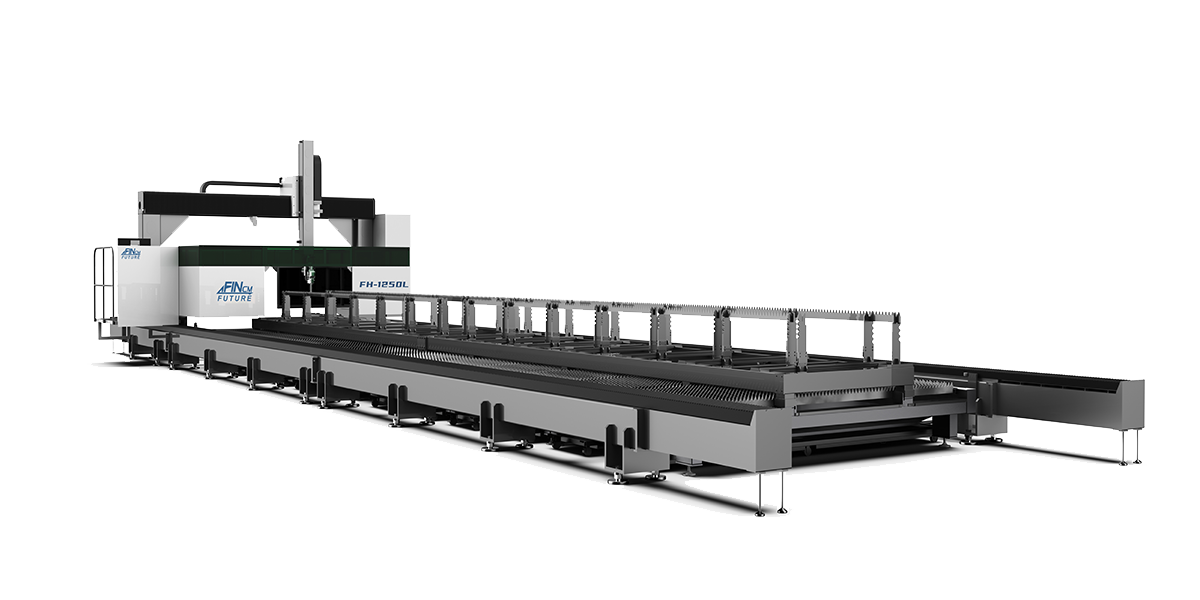

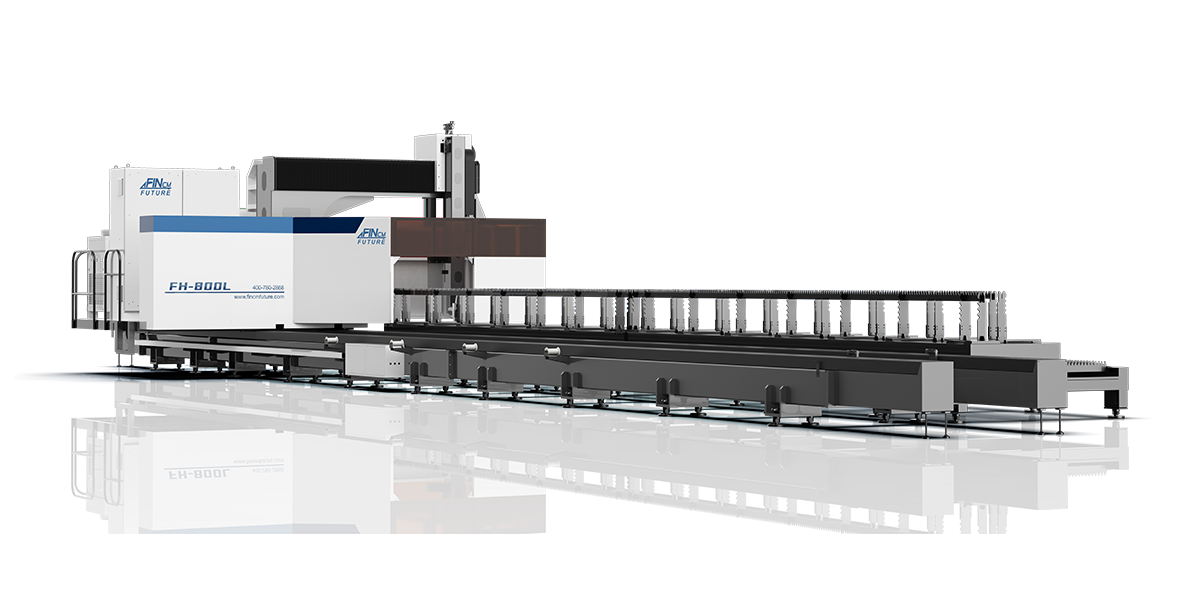

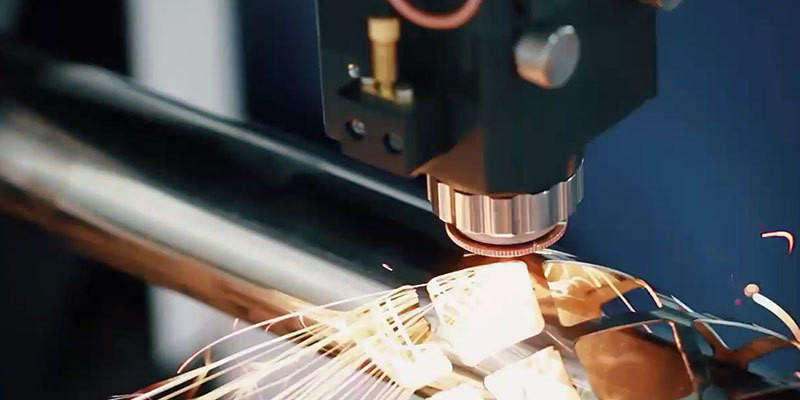

The characteristics of 1. laser cutting machine Laser cutting machine is an advanced processing equipment, which uses high-energy laser beam to irradiate the surface of the material, so that the material quickly melts, vaporizes or reaches the ignition point, and at the same time blows away the melted or burned material with high-speed airflow, So as to achieve cutting. The laser cutting machine has the following characteristics: High precision: The focusing accuracy of the laser beam is very high, which can reach below the micron level, so it can achieve high-precision cutting. High speed: The cutting speed of the laser cutting machine is very fast, which can greatly improve the production efficiency. High degree of automation: The laser cutting machine adopts advanced control systems and sensors, which can realize automatic operation and reduce labor costs. Wide range of applications: Laser cutting machines can be used for cutting various materials, including metals, non-metals, and composite materials. Environmental protection and energy saving: The laser cutting machine produces less waste during work, low energy consumption, and has the characteristics of environmental protection and energy saving.

The application of 2. laser cutting machine in the electronics industry Integrated circuit board cutting Integrated circuit board is one of the core components of electronic products. The laser cutting machine can be used to cut various integrated circuit boards, such as PCB boards, FP boards, etc. The cutting precision is high and the speed is fast, which can meet the high requirements of electronic manufacturing. Electronic components are the basic components of electronic products. The laser cutting machine can be used to cut various electronic components, such as resistors, capacitors, diodes, etc. The cutting precision is high and the speed is fast, which can meet the high requirements of electronic manufacturing. Circuit board welding Laser welding is a high-precision welding method, suitable for welding various circuit boards. Laser welding can improve the stability and reliability of welding, while improving production efficiency. Micro device processing laser processing is suitable for the processing of various micro devices, such as laser drilling, laser etching, etc. These technologies increase productivity while ensuring high accuracy and consistency.

3. the advantages of laser cutting machines in the electronics industry to improve production efficiency: The cutting speed of laser cutting machines is very fast, which can greatly improve the production efficiency of electronic manufacturing. Improve product quality: The precision of the laser cutting machine is very high, which can reach below the micron level, so it can improve the quality of electronic products. Reduce production costs: the use of laser cutting machine can reduce waste and loss, so it can reduce the production cost of electronic manufacturing. Enhance market competitiveness: The laser cutting machine has a high degree of automation and can achieve fast and efficient mass production, so it can improve the market competitiveness of electronic products. High reliability: There is no contact in the laser processing process, which reduces mechanical stress and avoids adverse effects such as chemical corrosion, thereby ensuring extremely high process reliability and product reliability. Environmental protection and energy saving: The auxiliary gas used in the laser processing process is only air or nitrogen, which is pollution-free to the environment and meets environmental protection requirements. At the same time, the laser processing equipment is compact, the energy conversion efficiency is high, and it has the advantage of energy saving and environmental protection. In summary, laser cutting machine has been widely used in the electronics industry, its high precision, high speed and high efficiency, can improve production efficiency, improve product quality, reduce production costs, enhance market competitiveness and other advantages. With the continuous innovation and development of the electronics industry, the application prospects of laser cutting machines will be broader.

Key words:

Latest developments

Support

FINCM FUTURE provides you with 24/7 professional services, as well as diversified support plans and expert services to meet your needs from product use, routine maintenance to optimization and upgrading of the whole cycle, so that you can use FINCM products in this process more efficient and economical!