Application and advantages of laser cutting machine in aerospace field

Release time:

2023-11-15

Author:

Source:

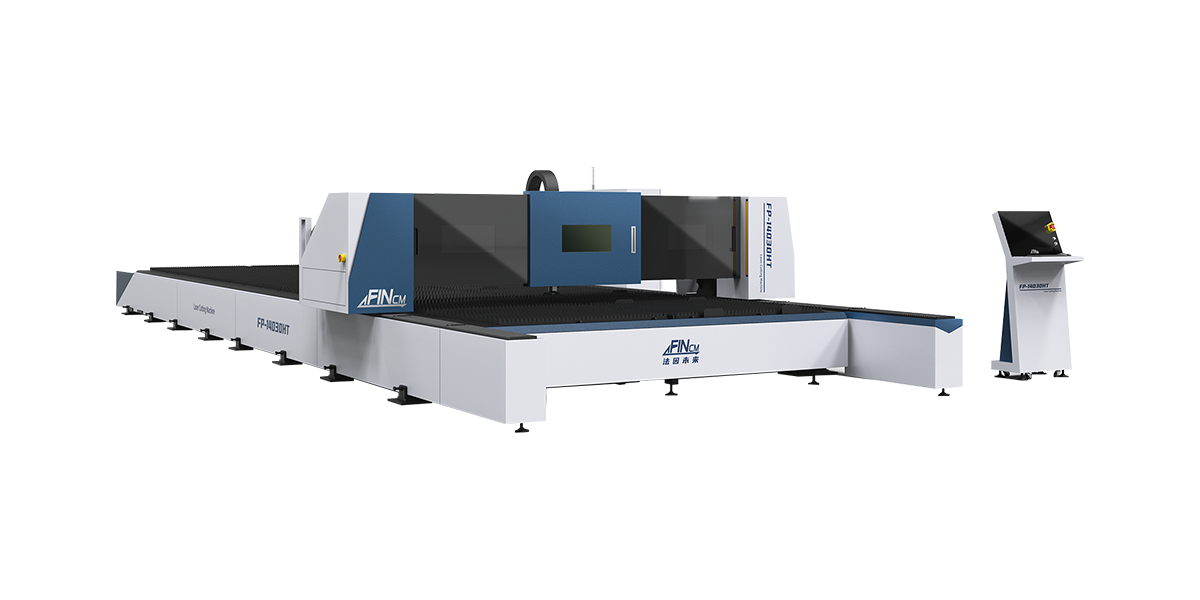

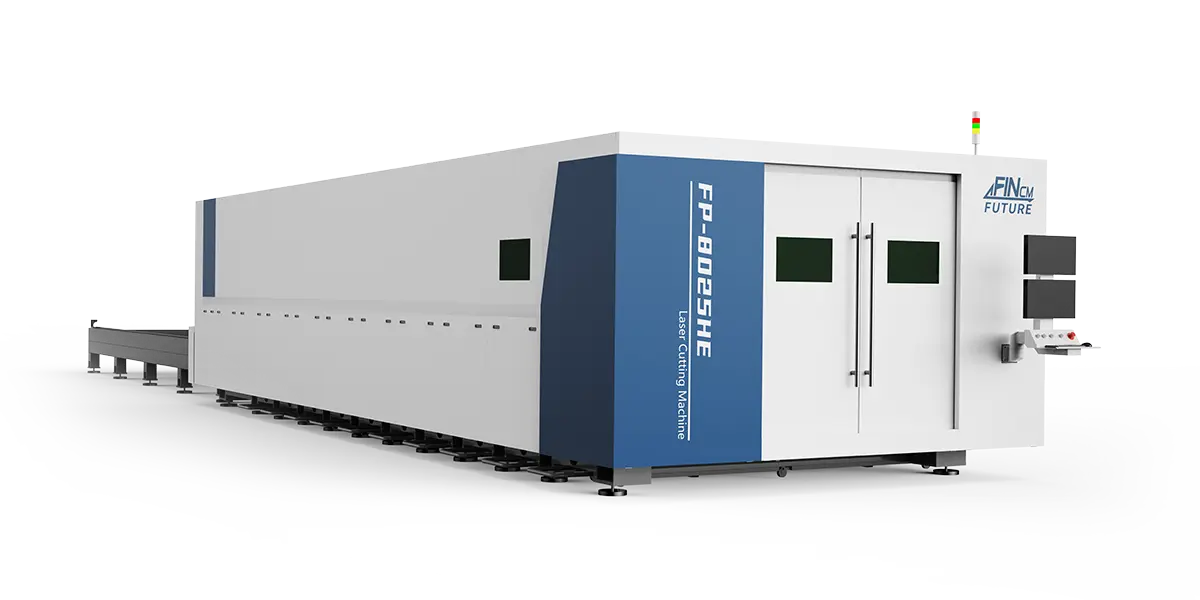

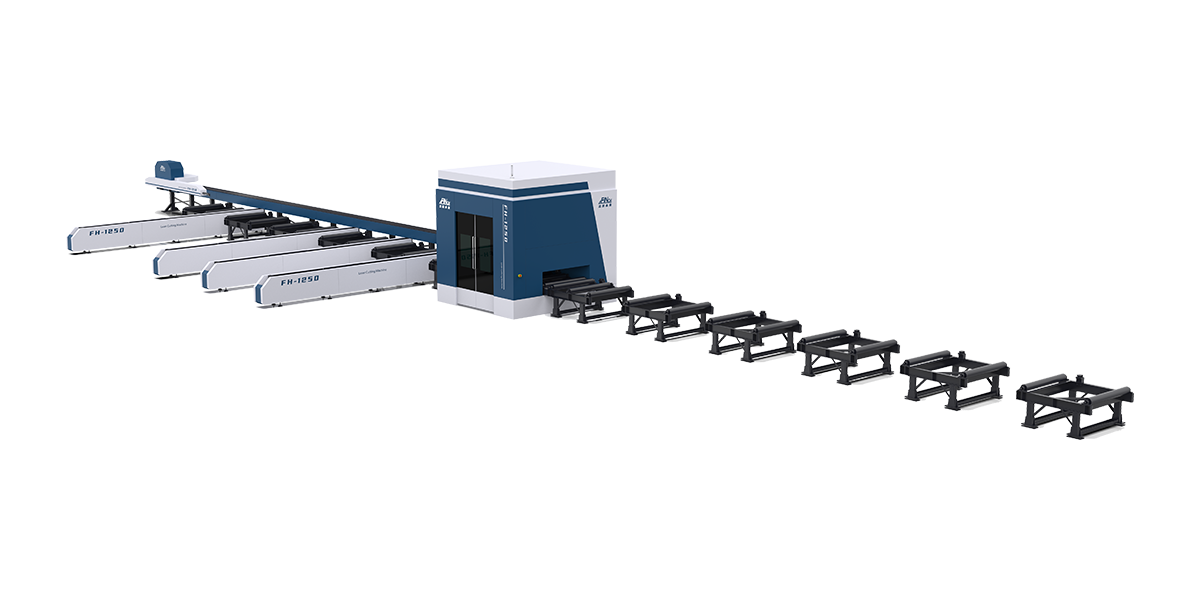

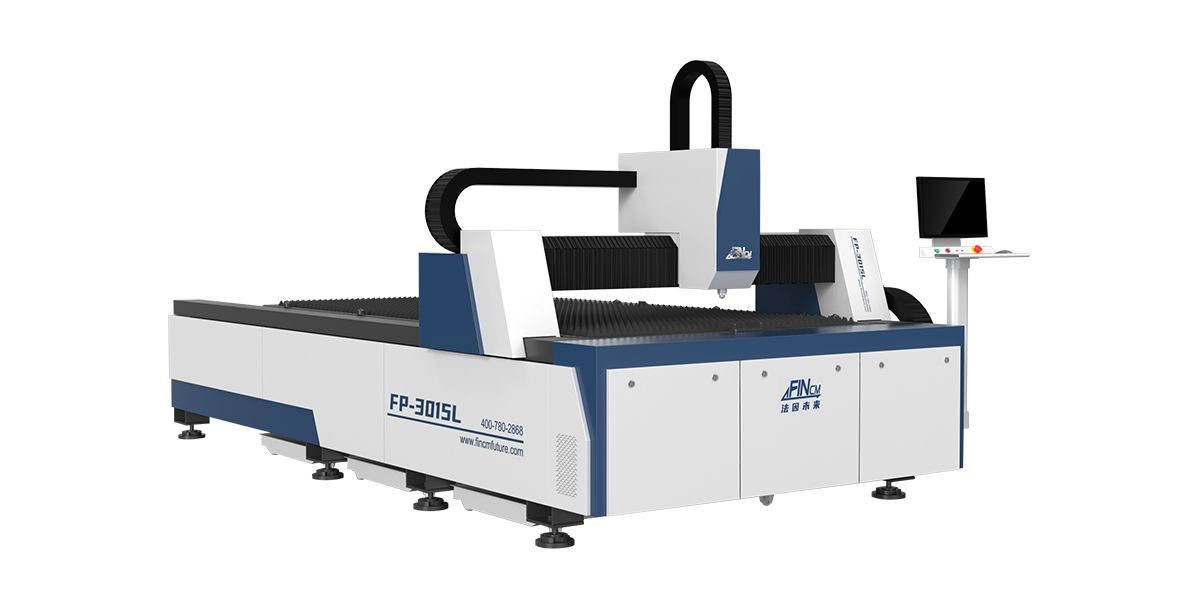

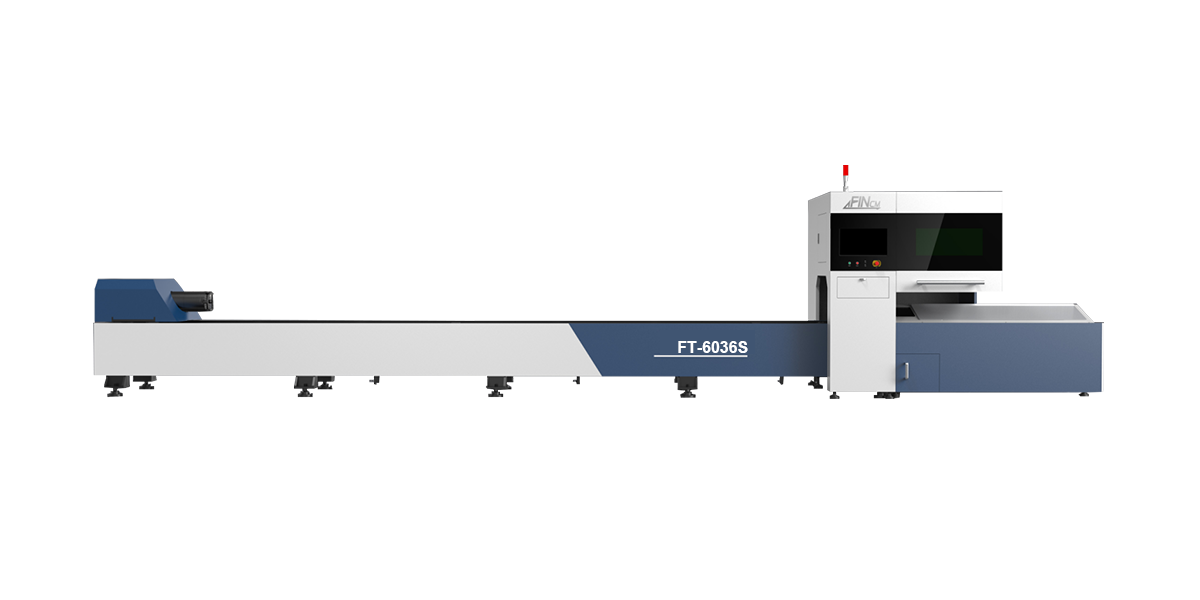

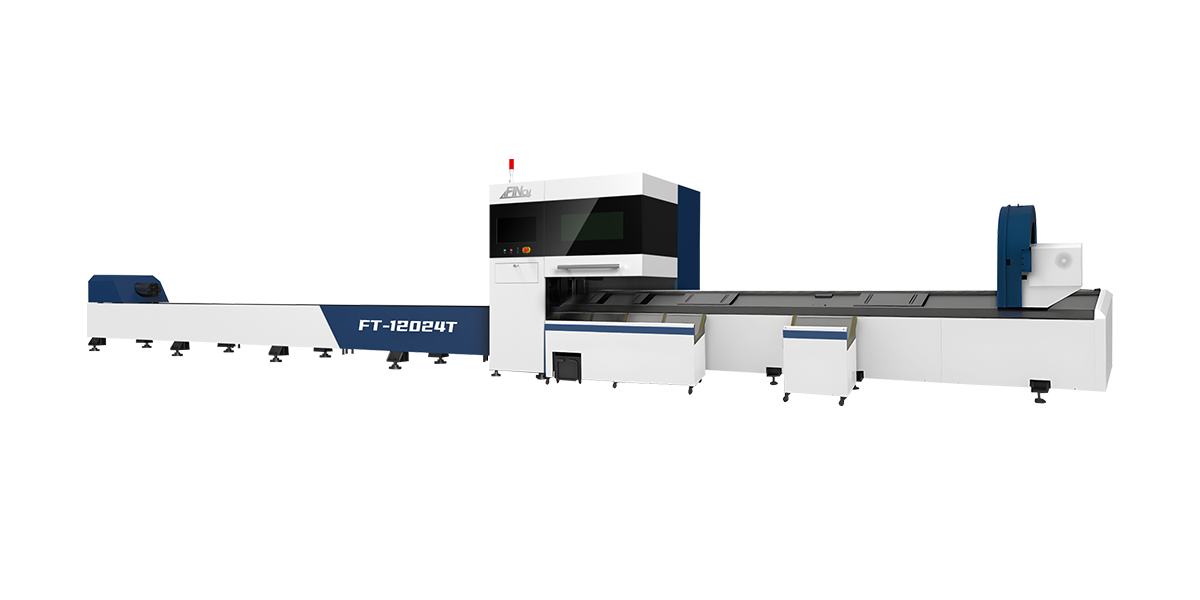

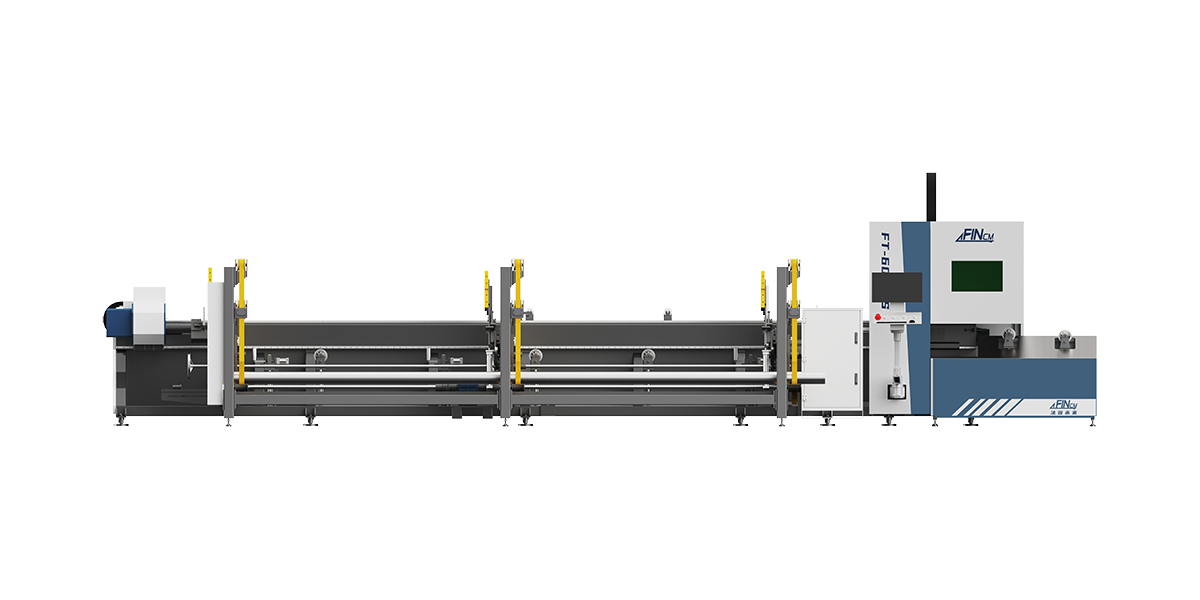

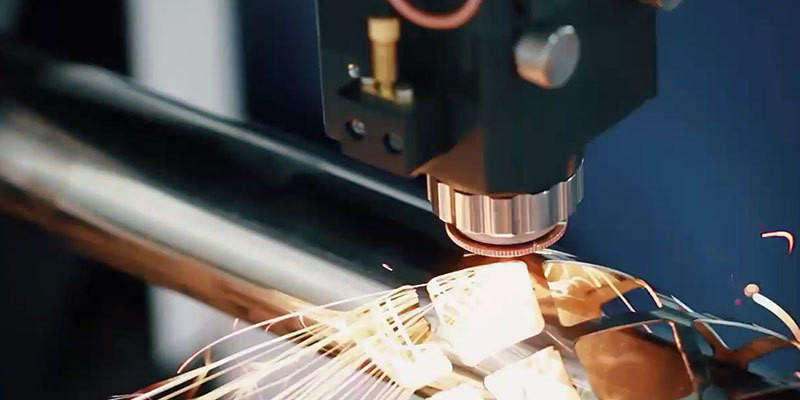

Laser cutting machine is an advanced processing equipment, which uses high-energy laser beam to cut materials, with high precision, high speed and high efficiency. In the aerospace field, laser cutting machines are widely used in the cutting of various materials, such as aluminum alloys, titanium alloys, high-temperature alloys, etc., to improve production efficiency and product quality. This article will introduce the application and advantages of laser cutting machine in the field of aerospace, to help you better understand its application in this field.

Laser cutting machine is an advanced processing equipment, which uses high-energy laser beam to cut materials, with high precision, high speed and high efficiency. In the aerospace field, laser cutting machines are widely used in the cutting of various materials, such as aluminum alloys, titanium alloys, high-temperature alloys, etc., to improve production efficiency and product quality. This article will introduce the application and advantages of laser cutting machine in the field of aerospace, to help you better understand its application in this field.

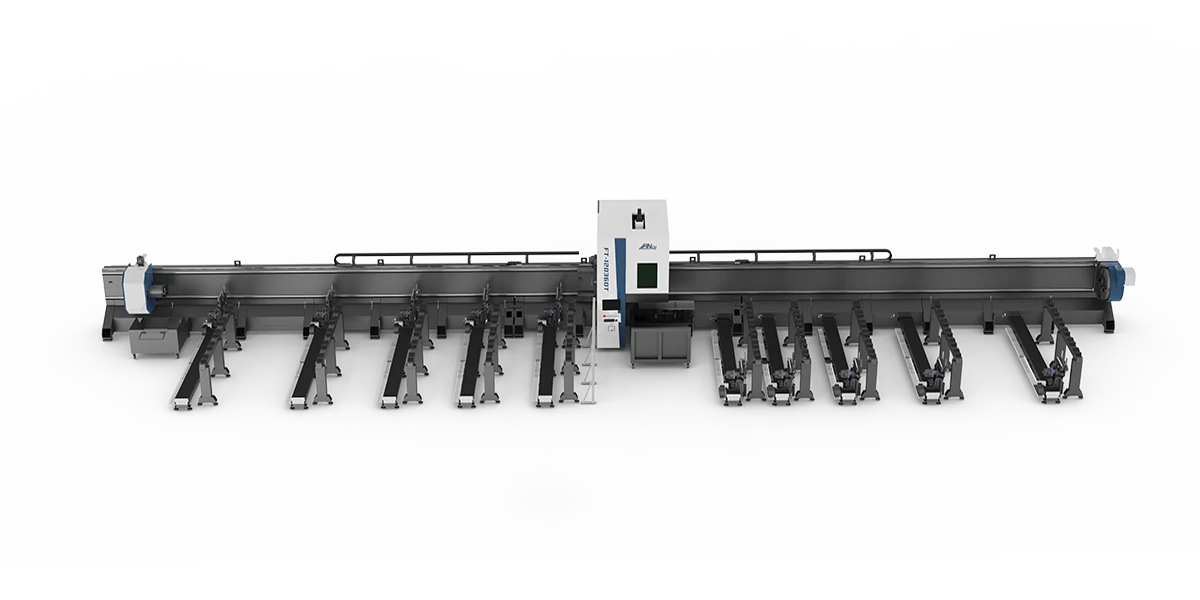

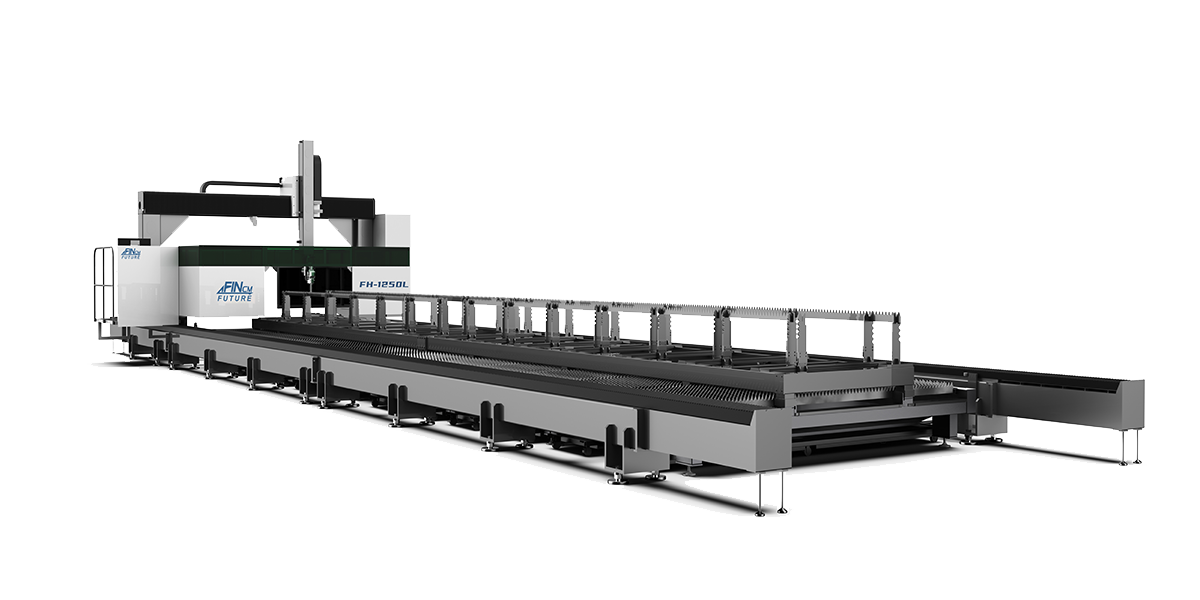

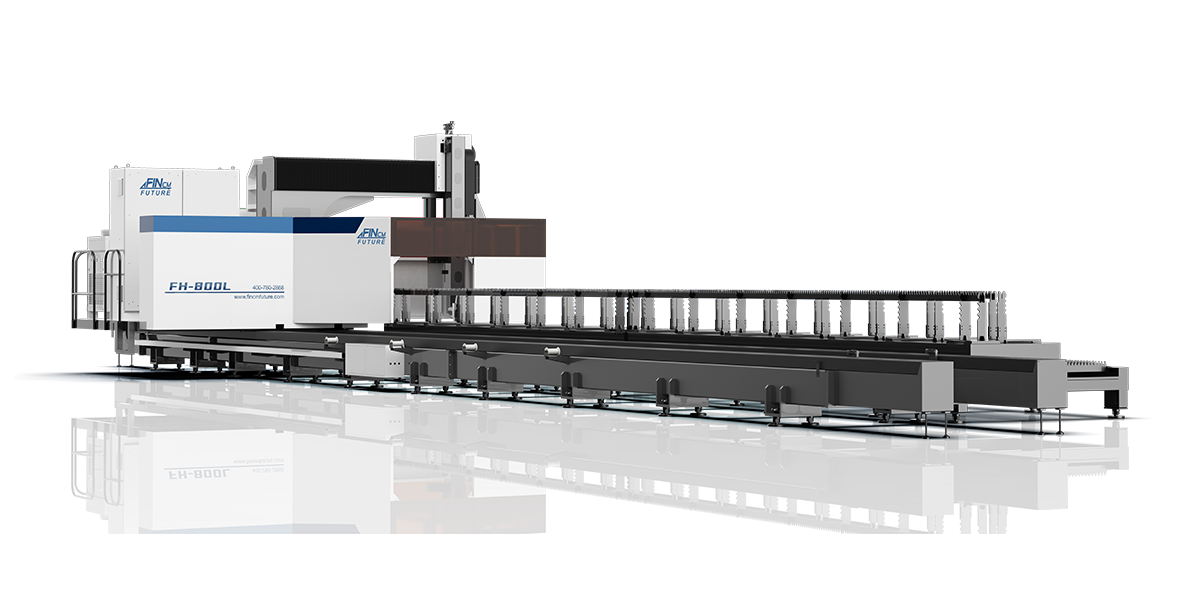

The characteristics of 1. laser cutting machine Laser cutting machine is an advanced processing equipment, which uses high-energy laser beam to irradiate the surface of the material, so that the material quickly melts, vaporizes or reaches the ignition point, and at the same time blows away the melted or burned material with high-speed airflow, So as to achieve cutting. The laser cutting machine has the following characteristics: High precision: The focusing accuracy of the laser beam is very high, which can reach below the micron level, so it can achieve high-precision cutting. High speed: The cutting speed of the laser cutting machine is very fast, which can greatly improve the production efficiency. High degree of automation: The laser cutting machine adopts advanced control systems and sensors, which can realize automatic operation and reduce labor costs. Wide range of applications: Laser cutting machines can be used for cutting various materials, including metals, non-metals, and composite materials. Environmental protection and energy saving: The laser cutting machine produces less waste during work, low energy consumption, and has the characteristics of environmental protection and energy saving.

Application of 2. Laser Cutting Machine in Aerospace Aircraft Structural Parts Cutting aircraft structural parts is an important part of aircraft manufacturing. Laser cutting machine can be used to cut all kinds of aircraft structural parts, such as wings, fuselage, tail and so on. The cutting precision is high and the speed is fast, which can meet the high requirements of aircraft manufacturing. Aeroengine parts cutting Aeroengine is the heart of aircraft. The laser cutting machine can be used to cut various aero-engine parts, such as turbine blades, fuel nozzles, etc. The cutting precision is high and the speed is fast, which can meet the high requirements of aero-engine manufacturing. Spacecraft parts cutting Spacecraft is an important tool for exploring space. The laser cutting machine can be used to cut various spacecraft parts, such as solar panels, guide rails, etc. The cutting precision is high and the speed is fast, which can meet the high requirements of spacecraft manufacturing.

3. the advantages of laser cutting machines in the aerospace field to improve production efficiency: The cutting speed of laser cutting machines is very fast, which can greatly improve the production efficiency of aerospace vehicles. Improve product quality: The precision of the laser cutting machine is very high, which can reach below the micron level, so it can improve the quality of the aerospace vehicle. Reduce production costs: the use of laser cutting machine can reduce waste and loss, so it can reduce the production cost of aerospace vehicle manufacturing. Enhance market competitiveness: The laser cutting machine has a high degree of automation and can achieve fast and efficient mass production, so it can improve the market competitiveness of aerospace vehicles. High reliability: There is no contact in the laser processing process, which reduces mechanical stress and avoids adverse effects such as chemical corrosion, thereby ensuring extremely high process reliability and product reliability. Environmental protection and energy saving: The auxiliary gas used in the laser processing process is only air or nitrogen, which is pollution-free to the environment and meets environmental protection requirements. At the same time, the laser processing equipment is compact, the energy conversion efficiency is high, and it has the advantage of energy saving and environmental protection.

To sum up, laser cutting machine has a wide range of application prospects in the field of aerospace, its high precision, high speed and high efficiency, can improve production efficiency, improve product quality, reduce production costs, enhance market competitiveness and other advantages. With the continuous development of aerospace technology, the application prospect of laser cutting machine will be broader.

Key words:

Latest developments

Support

FINCM FUTURE provides you with 24/7 professional services, as well as diversified support plans and expert services to meet your needs from product use, routine maintenance to optimization and upgrading of the whole cycle, so that you can use FINCM products in this process more efficient and economical!