Safety operation specification and precautions of laser cutting machine

Release time:

2023-11-15

Author:

Source:

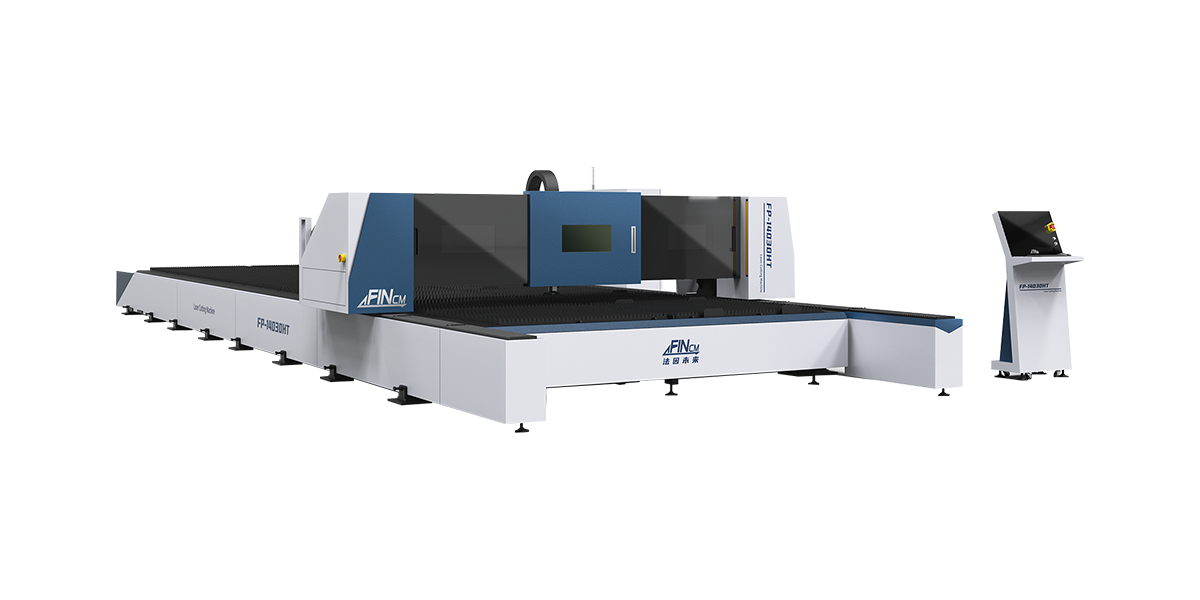

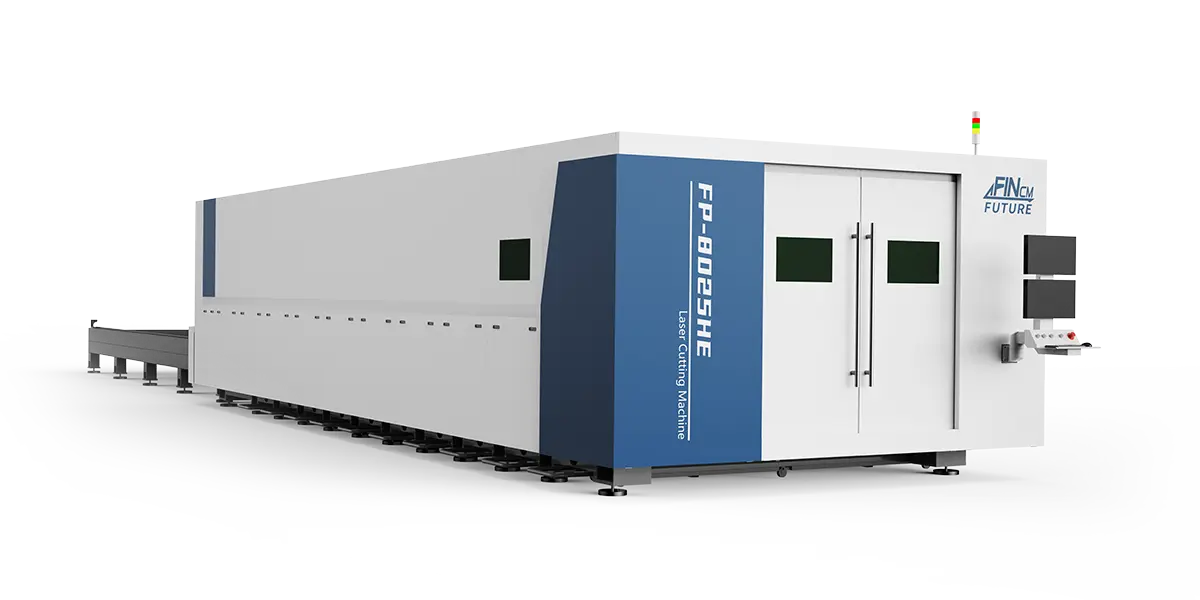

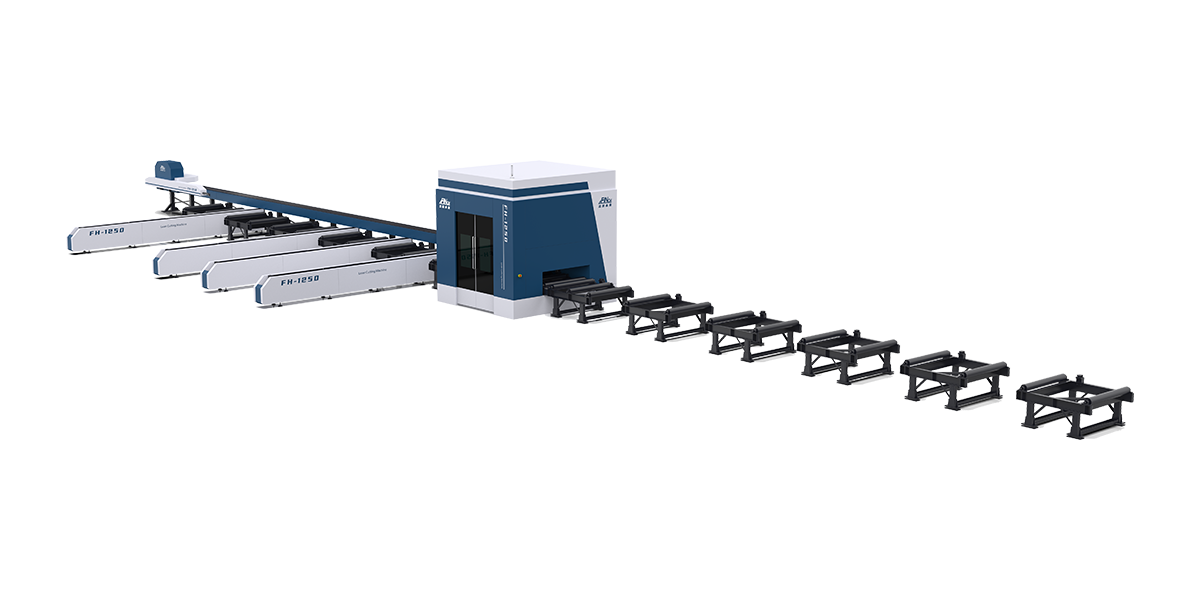

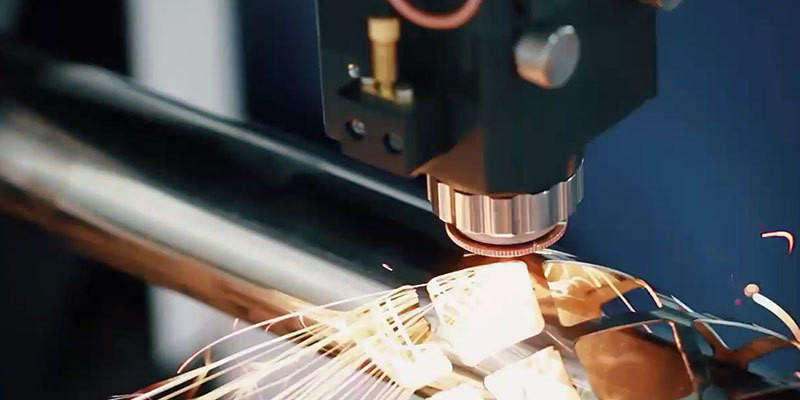

Laser cutting machine is a kind of processing equipment widely used in all walks of life. It uses high-energy laser beam to irradiate the surface of the material to make the material melt, vaporize or reach the ignition point quickly, and at the same time, the molten or burning material is blown away by high-speed airflow, so as to realize cutting. Although the laser cutting machine has the characteristics of high efficiency, high precision and high speed, it also has certain safety risks. Therefore, it is very important to master the safety operation specifications and precautions of laser cutting machines. This article will introduce the safety operation specifications and precautions of the laser cutting machine to help everyone better understand and use the laser cutting machine.

Laser cutting machine is a kind of processing equipment widely used in all walks of life. It uses high-energy laser beam to irradiate the surface of the material to make the material melt, vaporize or reach the ignition point quickly, and at the same time, the molten or burning material is blown away by high-speed airflow, so as to realize cutting. Although the laser cutting machine has the characteristics of high efficiency, high precision and high speed, it also has certain safety risks. Therefore, it is very important to master the safety operation specifications and precautions of laser cutting machines. This article will introduce the safety operation specifications and precautions of the laser cutting machine to help everyone better understand and use the laser cutting machine.

1. the safe operation specifications of the laser cutting machine Before operating the laser cutting machine, the following preparations need to be made: Check whether the power supply and air supply are normal; Check whether there are obstructions or idle personnel around the machine; Check whether the laser tube is damaged or cracked; Check whether the cooling water tank is short of water and clean. Operating steps When operating the laser cutting machine, you need to follow the following steps: wear personal protective equipment, such as protective glasses, protective gloves, etc. as required; select the appropriate cutting speed and power as required; place the material to be cut on the cutting table and fix it; select the appropriate blowing volume as required; press the laser switch to adjust the position and shape of the laser beam; start cutting, and according to the need to adjust the parameters in a timely manner. After operation, pay attention to the following matters after operating the laser cutting machine: turn off the laser cutting machine and clean up the waste generated by cutting in time; check whether there is any abnormal sound or smell inside the machine; clean and maintain the machine.

2. Precautions In the process of using the laser cutting machine, the following matters need to be paid attention to: It is forbidden for non-professionals to operate the laser cutting machine to avoid safety accidents; before any operation, you must understand the performance and operating instructions of the machine to avoid accidents; During the operation, you must keep your attention and stop the machine for inspection in time if any abnormal situation is found; frequently check whether the various parts of the machine are working properly, if any abnormal situation is found, stop the machine in time for inspection; when using the laser cutting machine, pay attention to protect the eyes to avoid being irradiated by the laser beam; during maintenance, the power supply and air supply of the laser cutting machine must be turned off to avoid accidents; when carrying out any cleaning and maintenance work, the corresponding safety protection equipment must be worn.

Key words:

Latest developments

Support

FINCM FUTURE provides you with 24/7 professional services, as well as diversified support plans and expert services to meet your needs from product use, routine maintenance to optimization and upgrading of the whole cycle, so that you can use FINCM products in this process more efficient and economical!