The Method of Improving the Precision and Speed of Laser Cutting Machine

Release time:

2023-11-15

Author:

Source:

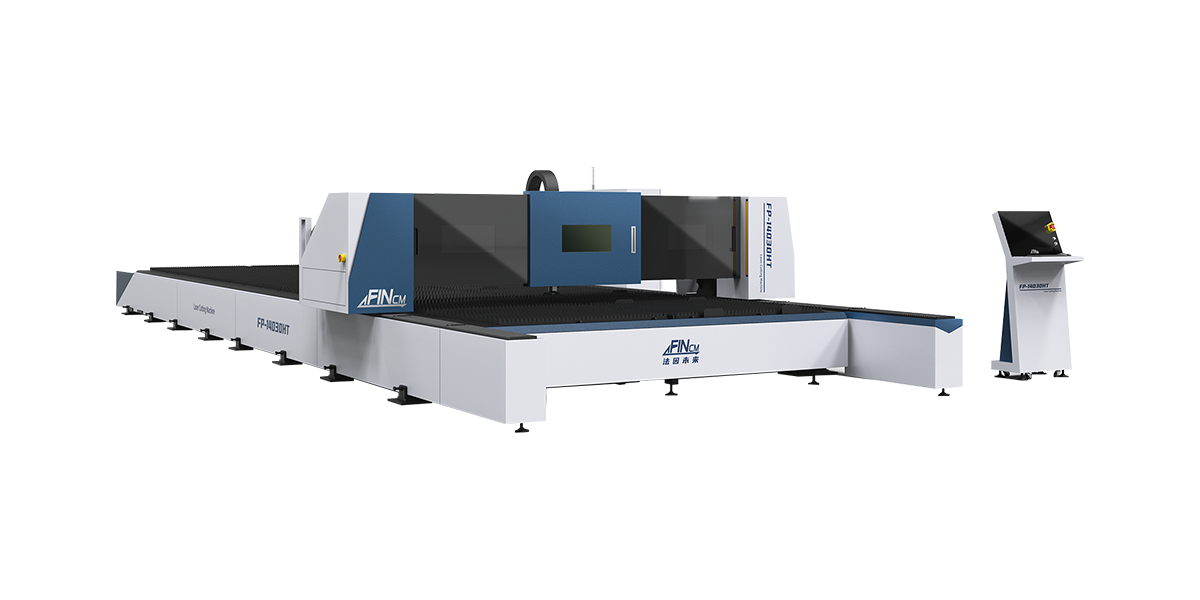

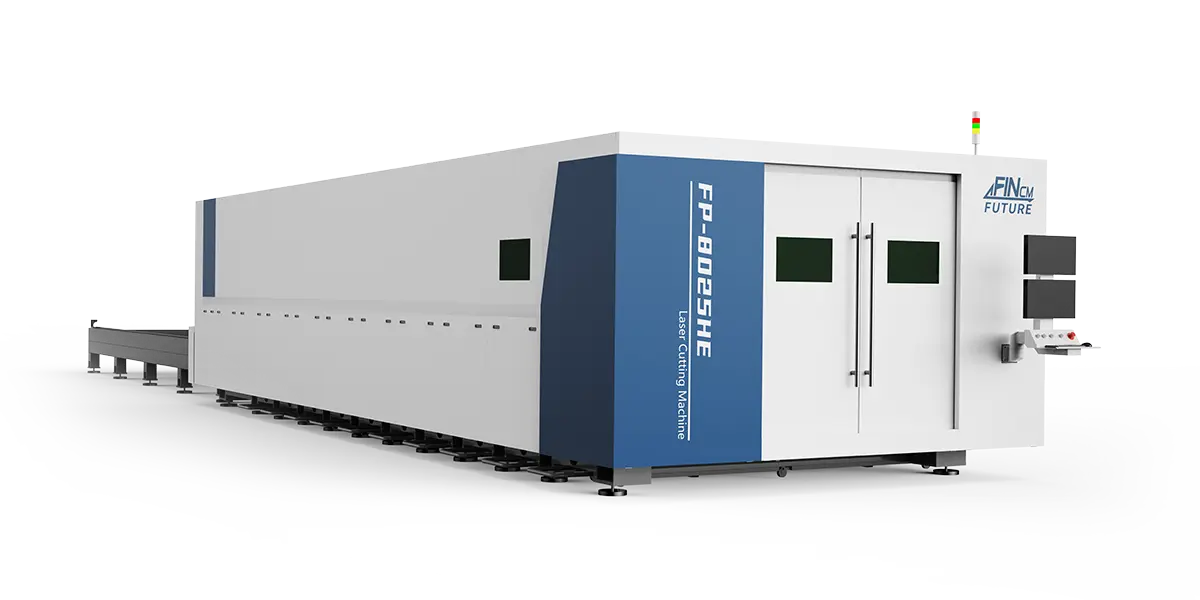

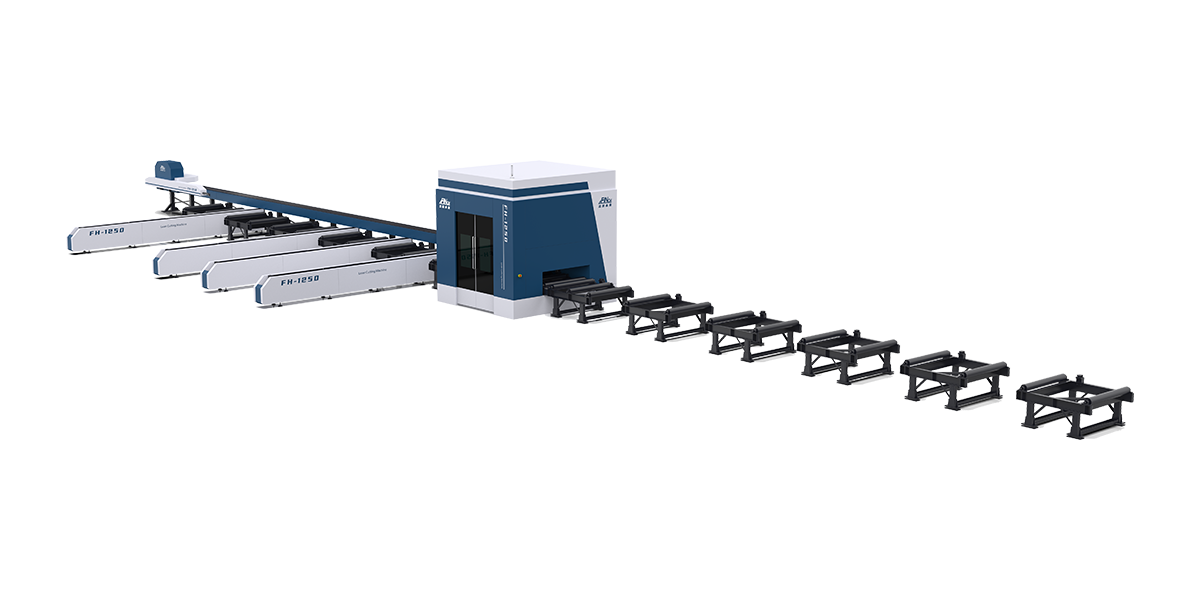

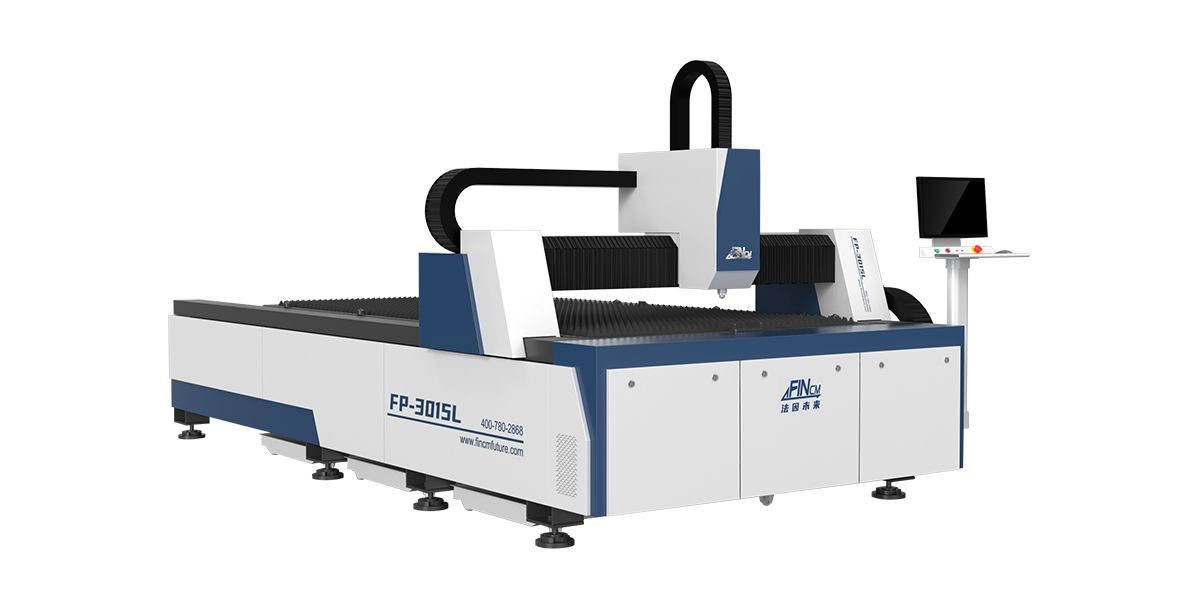

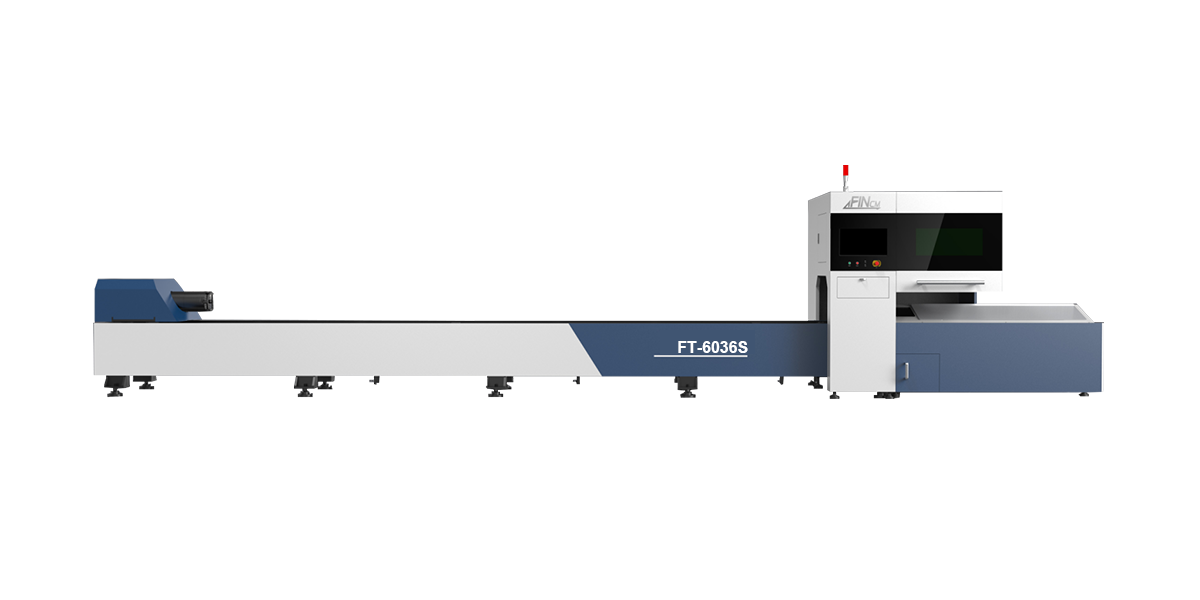

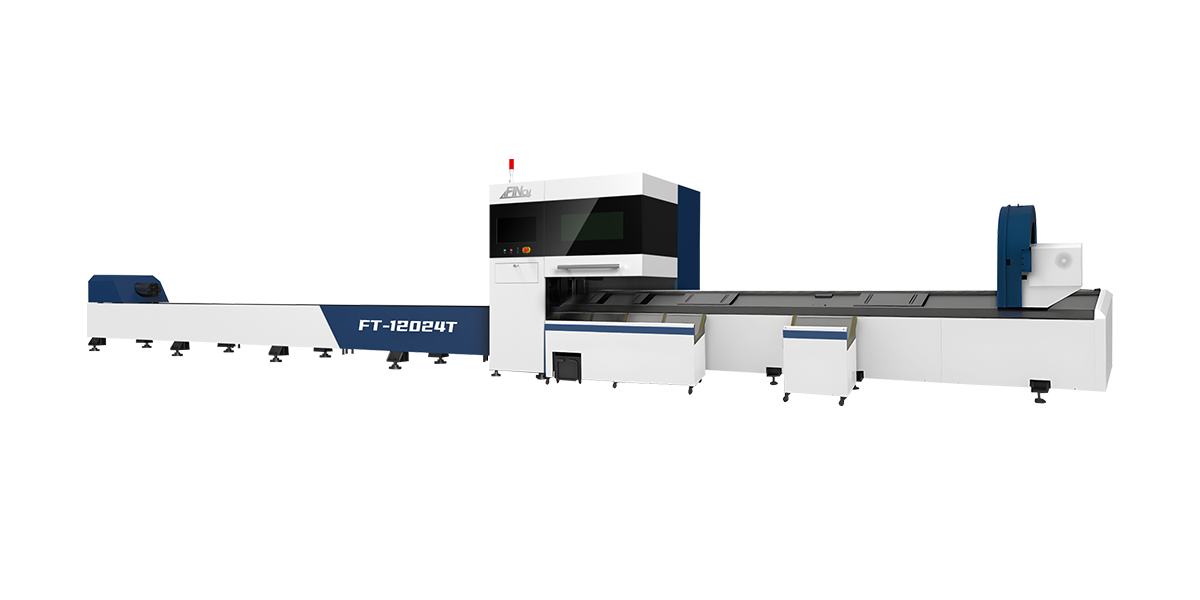

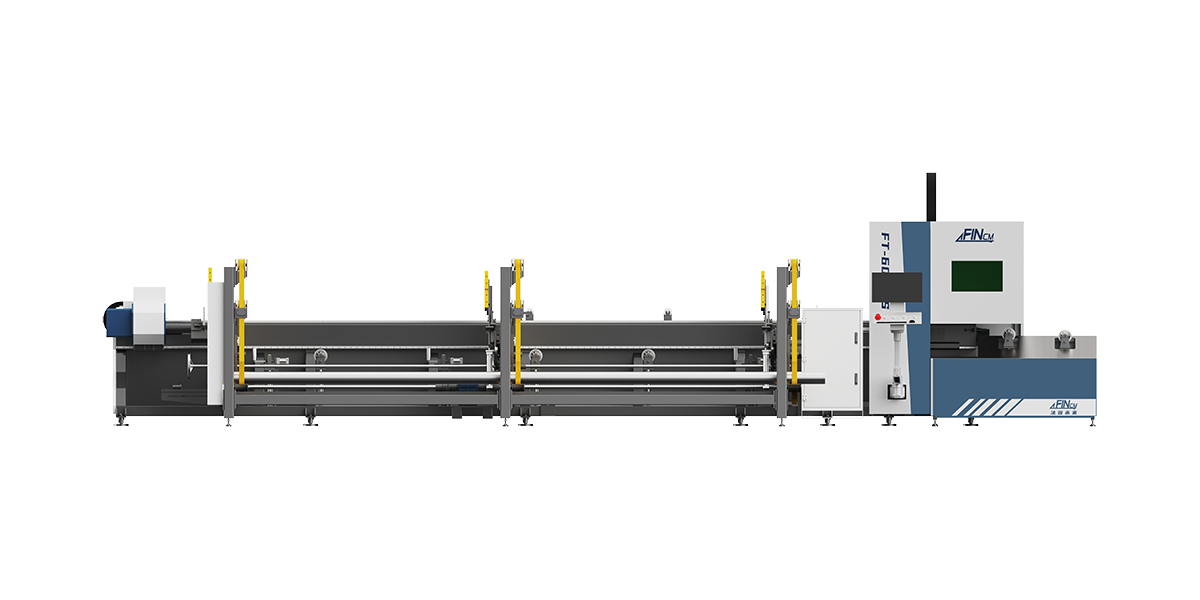

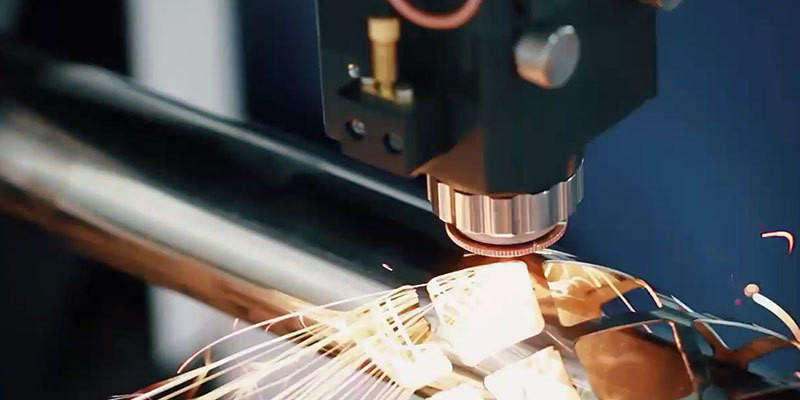

Laser cutting machine is a kind of advanced processing equipment widely used in all walks of life. It uses a high-energy laser beam to irradiate the surface of the material, so that the material quickly melts, vaporizes or reaches the ignition point, and at the same time, the molten or burning material is blown away by a high-speed airflow to achieve cutting. This article will introduce the accuracy and speed improvement method of laser cutting machine.

Laser cutting machine is a kind of advanced processing equipment widely used in all walks of life. It uses a high-energy laser beam to irradiate the surface of the material, so that the material quickly melts, vaporizes or reaches the ignition point, and at the same time, the molten or burning material is blown away by a high-speed airflow to achieve cutting. This article will introduce the accuracy and speed improvement method of laser cutting machine.

1. the method of improving the accuracy of laser cutting Select high-precision laser and optical system The focus accuracy of the laser and the modulation accuracy of the optical system directly affect the cutting accuracy of the laser cutting machine. Therefore, the choice of high-precision laser and optical system is the key to improve the accuracy of laser cutting machine. In general, the focusing accuracy of the laser should be below the micron level, and the modulation accuracy of the optical path system should be below the nanometer level. Optimization of cutting parameters and cutting path The optimization of cutting parameters and cutting path is also an important measure to improve the accuracy of laser cutting machine. By adjusting the power, speed, gas pressure and other parameters of the laser beam, and optimizing the planning of the cutting path, the cutting error can be reduced and the cutting accuracy can be improved. Advanced control systems and sensors can help laser cutting machines achieve more accurate cutting. For example, using a closed-loop control system can monitor errors in the cutting process in real time and adjust them. At the same time, the use of sensors to accurately position the material can help the laser beam to align the cutting area and reduce errors.

2. the method of improving the laser cutting speed to improve the performance of the laser and the optical path system to improve the power of the laser and the modulation speed of the optical path system can accelerate the cutting speed of the laser cutting machine. At present, high-power fiber lasers and high-speed optical path systems have been widely used, which can help laser cutting machines achieve high-speed cutting. The use of advanced cutting processes and algorithms is also an effective way to improve the speed of laser cutting. For example, the use of high-precision large spot cutting process can reduce the number of cutting, improve cutting efficiency. At the same time, the optimization algorithm is used to plan the cutting path, which can reduce the empty travel time and speed up the cutting speed. Strengthening equipment maintenance and maintenance Strengthening the equipment maintenance and maintenance of the laser cutting machine can ensure the normal operation of the equipment, reduce downtime, and improve production efficiency. Regular overhaul and maintenance of the equipment and replacement of worn parts can help the laser cutting machine to maintain high efficiency.

To sum up, to improve the accuracy and speed of laser cutting machine needs to be considered from many aspects. The precision of laser cutting machine can be improved by selecting high-precision laser and optical path system, optimizing cutting parameters and cutting path, and adopting advanced control system and sensors. At the same time, improving the performance of the laser and optical path system, adopting advanced cutting technology and algorithms, and strengthening equipment maintenance and maintenance can also improve the speed of the laser cutting machine. When selecting and using laser cutting machines, it is necessary to consider the actual production needs and the use environment to achieve high-precision and high-speed cutting.

Key words:

Latest developments

Support

FINCM FUTURE provides you with 24/7 professional services, as well as diversified support plans and expert services to meet your needs from product use, routine maintenance to optimization and upgrading of the whole cycle, so that you can use FINCM products in this process more efficient and economical!