Medical Device Industry

1. industry introduction:

In the post-epidemic era, the non-epidemic medical device market recovered rapidly. Coupled with the structural changes in the population and the improvement of health awareness, China's medical device industry as a whole has entered a stage of rapid growth. From the perspective of the industrial chain, the upstream is dominated by various raw material suppliers and corresponding technology research and development enterprises. Midstream to all kinds of medical equipment, consumables related manufacturing enterprises. Downstream is dominated by various medical institutions, scientific research institutions, third-party inspection centers and C- end users. The construction of the domestic medical device industry chain is relatively perfect, and will gradually penetrate into the more high-end market in the future.

2. industry pain points:

1. The production supply chain is unstable: the supply chain substitutability is very low, and the production and certification conditions are very harsh, resulting in a very long supplier certification cycle.

2. Higher costs: shortage of upstream raw materials, insufficient plant capacity, labor and other production costs increase.

Application of 3. laser cutting machine in new energy industry:

laser welding

Usually in the use of reusable medical devices, laser welding can not only optimize the difficulties encountered in these traditional processes, such as the stability of the point, the density of the weld, etc., the production process also has high flexibility, and can achieve the medical device industry small batch multi-batch production requirements.

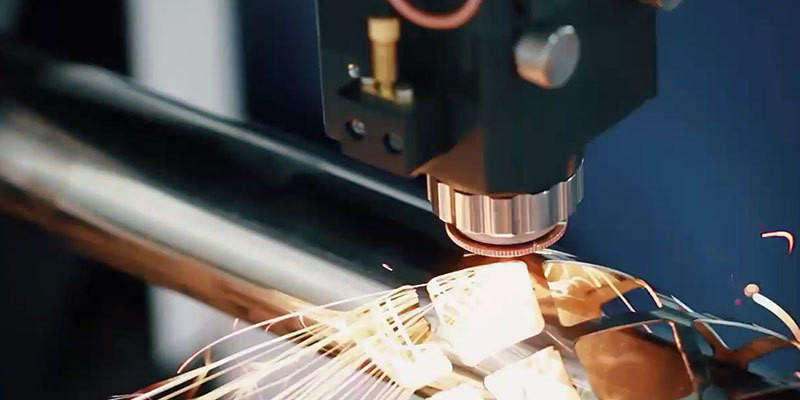

Laser cutting/punching

When cutting medical devices with complex shapes (such as cardiac stents, embolectomy stents, catheters, etc.), they are usually faced with difficulties such as burrs, multi-axis linkage, process control, etc., which affect the fine structure of the device. Laser technology can solve these problems and achieve high-flexibility precision cutting and punching processes.

laser marking

With reference to the manufacturing standards of China's medical machinery industry and FDA regulations in the United States, disposable and reusable medical devices need to create UDI marks and must be permanently marked. The use of laser marking can be marked with passivation corrosion resistance and high contrast. Laser marking technology can help realize difficult processing processes such as arc marking.

Support

FINCM FUTURE provides you with 24/7 professional services, as well as diversified support plans and expert services to meet your needs from product use, routine maintenance to optimization and upgrading of the whole cycle, so that you can use FINCM products in this process more efficient and economical!