Construction machinery industry

1. industry introduction:

Construction machinery refers to a series of construction machinery used in engineering construction projects. Construction machinery is generally composed of power devices, transmission devices, walking devices, working devices and control systems. From the perspective of the use of construction projects, these machines are widely used in railway and road construction, airport construction, water conservancy projects, power supply laying, housing construction, tunnel and bridge construction, mining, port transportation, national defense and military engineering fields. Construction machinery is an important part of China's equipment industry.

2. industry pain points:

1. Overcapacity: overall production capacity increased, homogenization and low-end products in the short term overcapacity appeared

2. High cost: the price of raw materials is rising, and the pressure of high cost of enterprises is increasing

3. Technical bottleneck: some high-end products supporting hydraulic, transmission, electronic control and other core components have short board problems

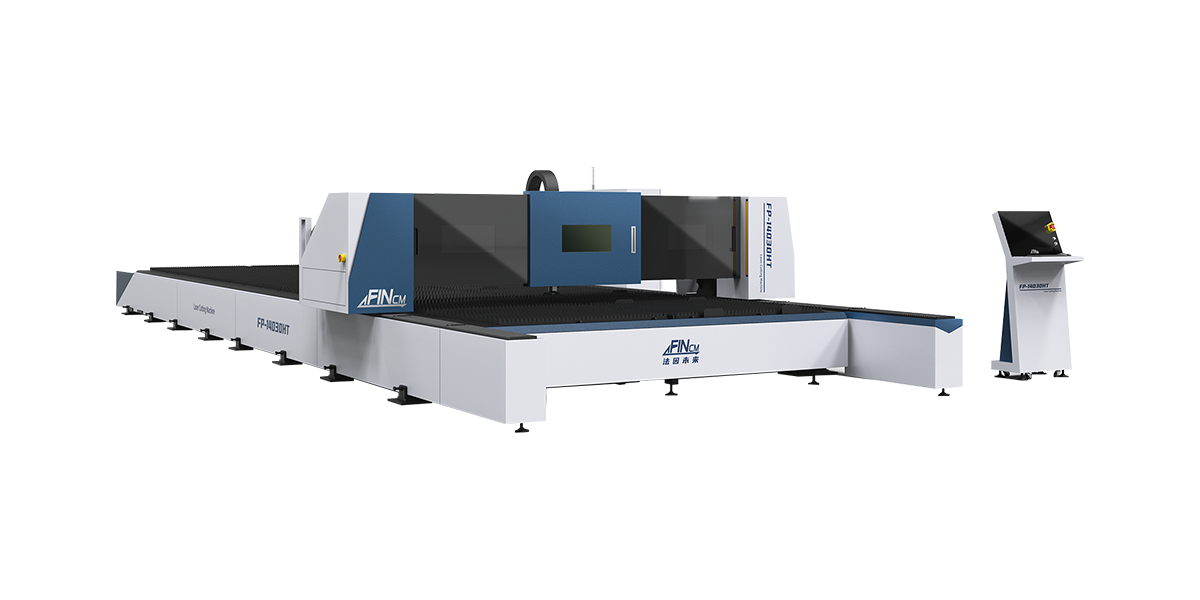

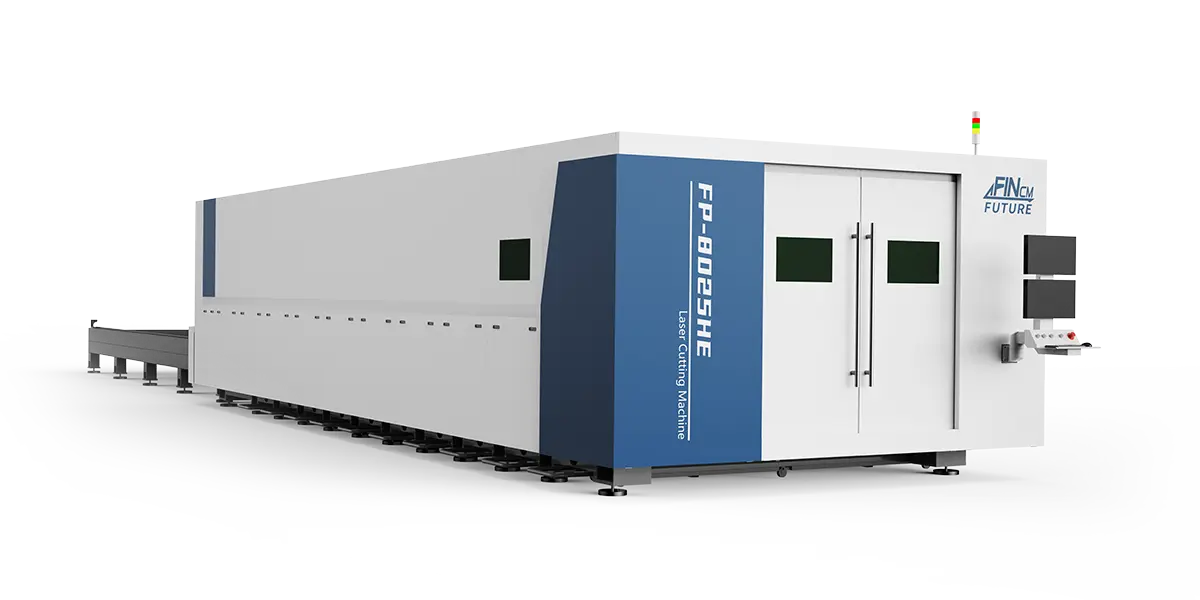

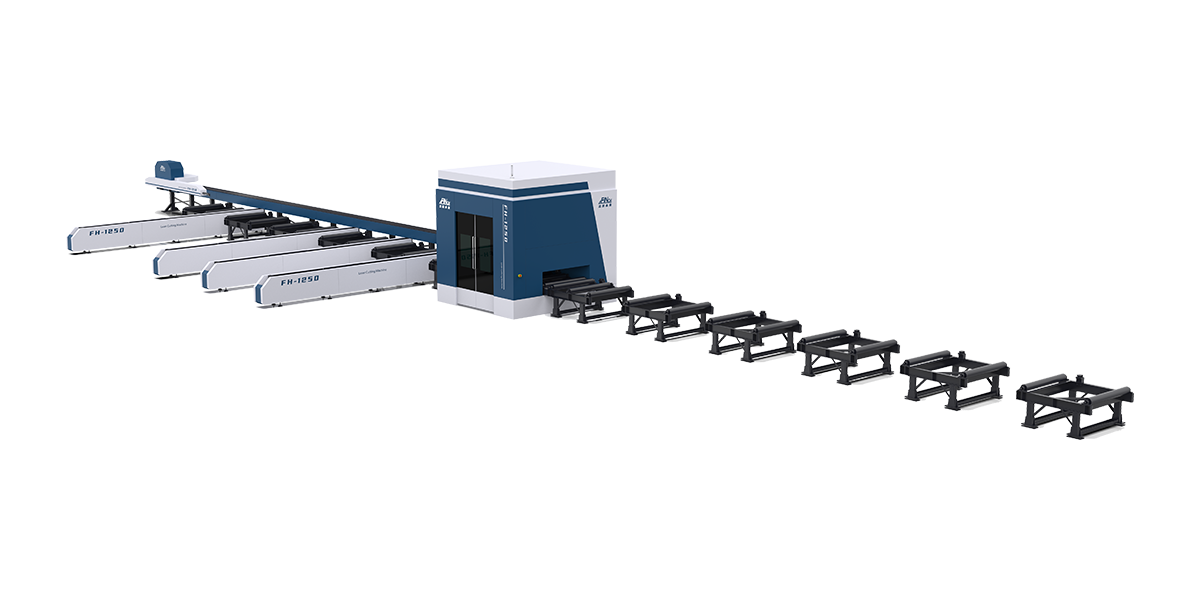

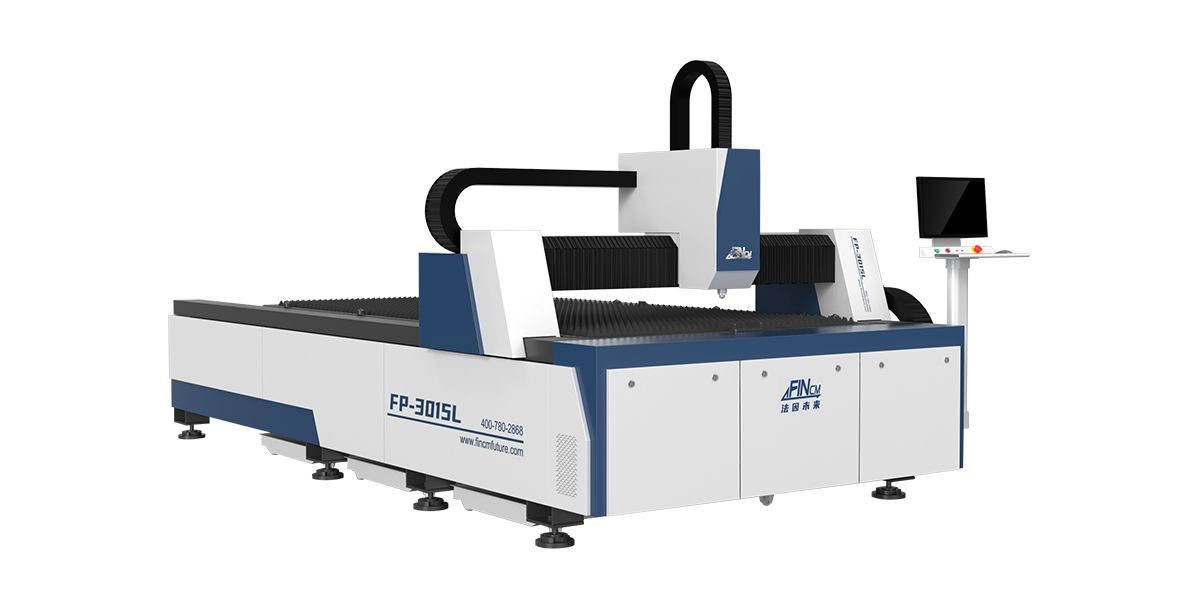

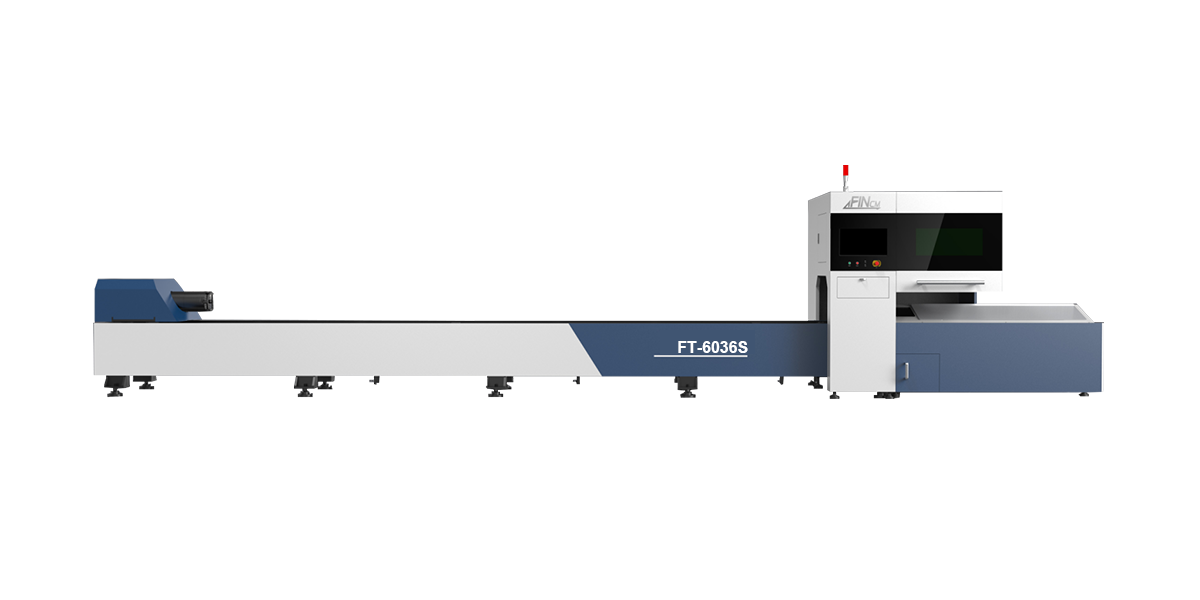

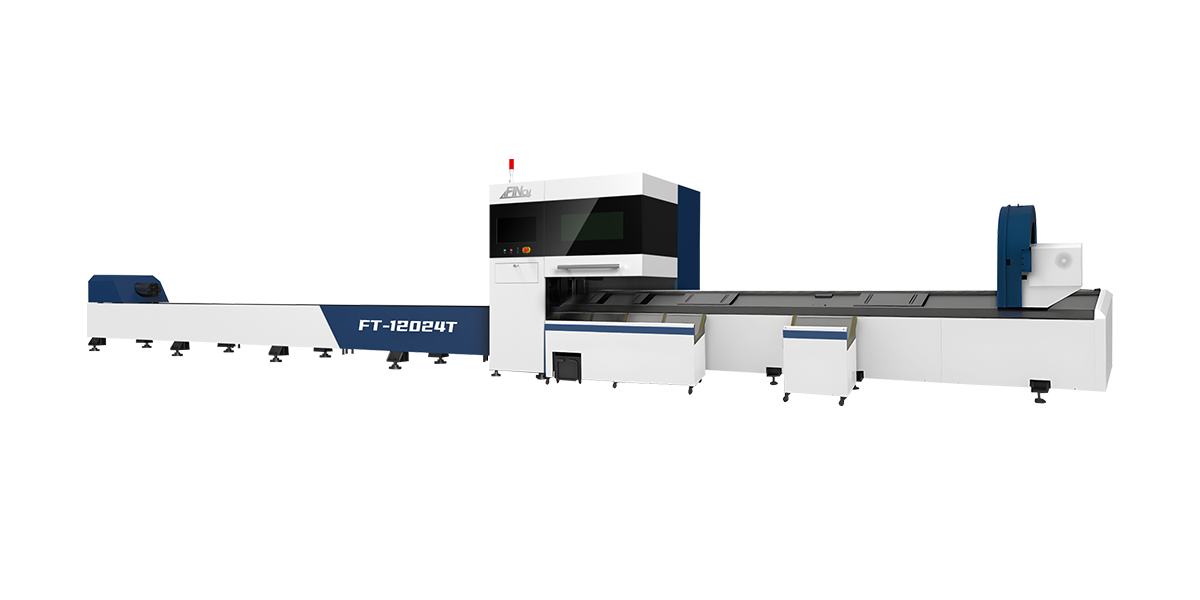

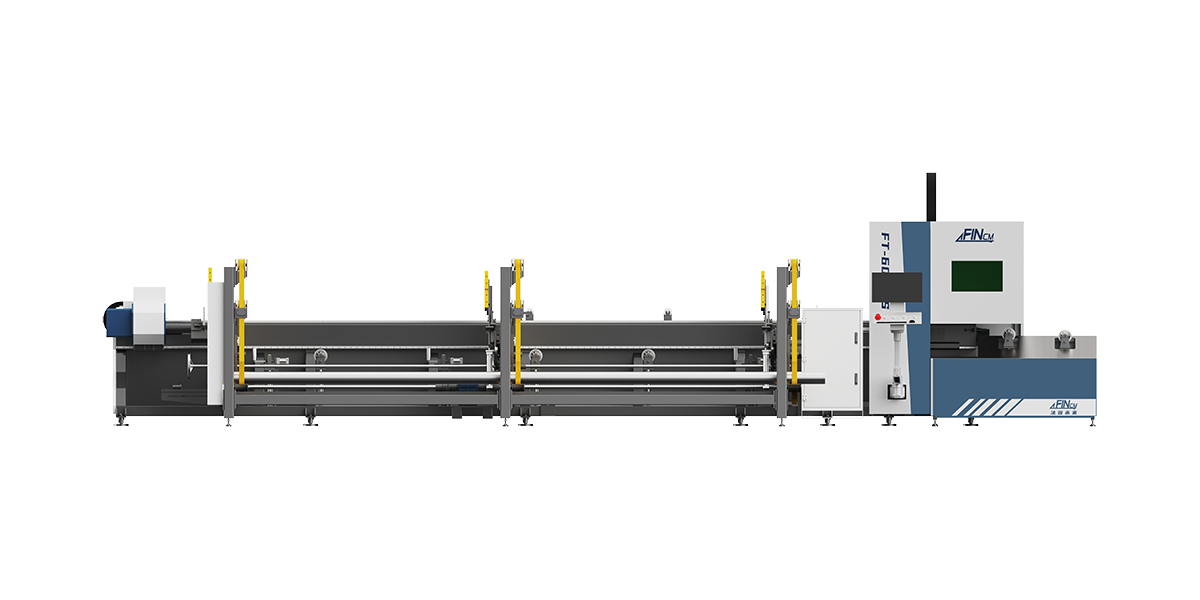

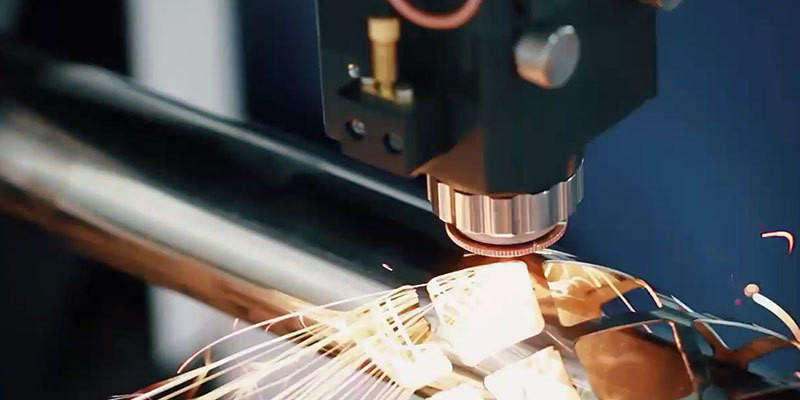

Application of 3. laser cutting machine in construction machinery industry:

Compared with traditional arc welding, laser welding technology is a precision welding method with convenient application, simple and reliable, strong adaptability and many functions. In construction machinery, laser welding is used to improve the welding strength. In the process of reducing welding deformation and welding correction, it has certain advantages and broad application prospects in improving the appearance and structure design.

Laser cladding is currently mainly used in the manufacturing process to repair damaged products and modify the appearance of materials. The laser cladding method can also be used as a vehicle commutator, gear and other components processing. Mold and roll processing is also widely used in laser cladding method to improve the surface hardness, abrasion resistance, high temperature resistance and other properties, to extend the use of time. The laser cladding method has also been successfully used to repair components such as engine blades, vehicle crankshafts, molds, etc. The performance of the repaired components can reach or even exceed that of new products, while the cost is greatly reduced.

Support

FINCM FUTURE provides you with 24/7 professional services, as well as diversified support plans and expert services to meet your needs from product use, routine maintenance to optimization and upgrading of the whole cycle, so that you can use FINCM products in this process more efficient and economical!