New energy industry

1. industry introduction:

The upstream industries of the new energy industry mainly include manufacturers of new energy and renewable energy power generation equipment such as solar energy, photovoltaic, hydro energy and wind energy, as well as manufacturers of new energy and renewable energy components and components such as solar energy, photovoltaic, hydro energy and wind energy. The midstream of the new energy industry, as an important link in the entire industrial chain, mainly includes energy suppliers such as hydrogen energy, photovoltaic power generation, wind power and hydropower. The downstream industries of the new energy industry mainly include public and personal applications such as new energy vehicles, hydrogenation stations, charging piles and power transmission and transformation.

2. industry pain points:

1. Technical bottleneck to be broken: According to the statistics of "Analysis Report on Development Prospect and Investment Strategic Planning of New Energy Industry" released by Prospective Industry Research Institute, it is estimated that by 2040, the proportion of natural gas in China's main energy structure will rise from less than 6% to 12%, of which the increase in natural gas production will mainly come from shale gas in unconventional gas. China has sufficient reserves of resources, but it needs to be strengthened in key engineering technologies and organizational systems. In order to truly achieve independence in energy security capacity building, independent technological breakthroughs are indispensable.

2. High cost: the cost of mining and utilization of emerging energy is still high, and it will take time to commercialize it. Although the theoretical data of shale gas reserves in China is large, the geological conditions are relatively at a disadvantage, which makes it difficult to exploit and the development cost is relatively high.

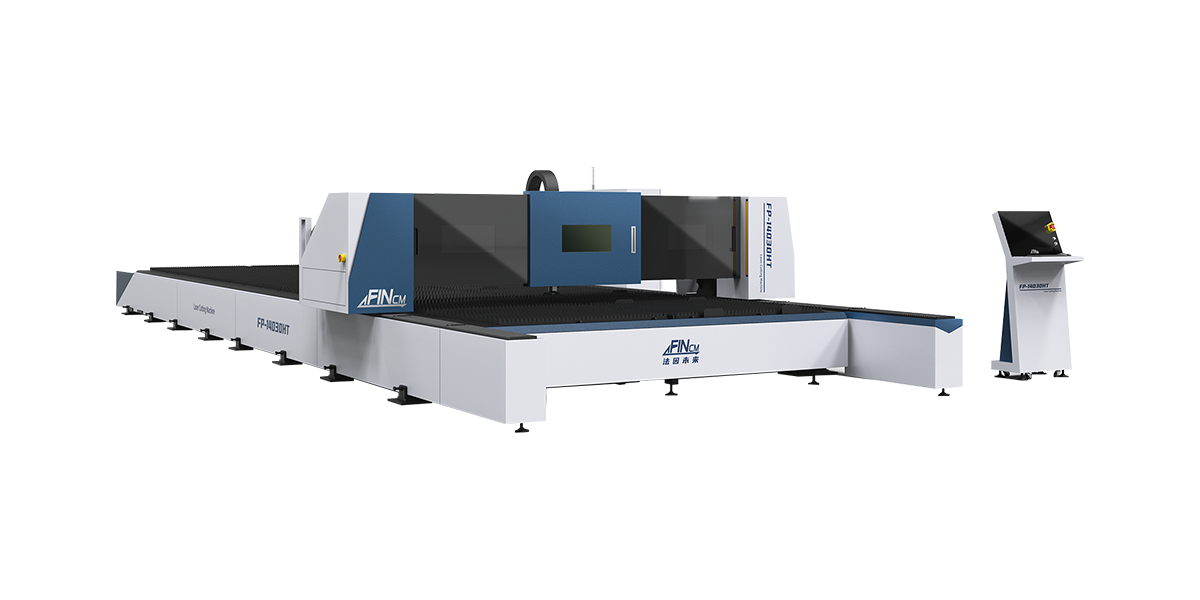

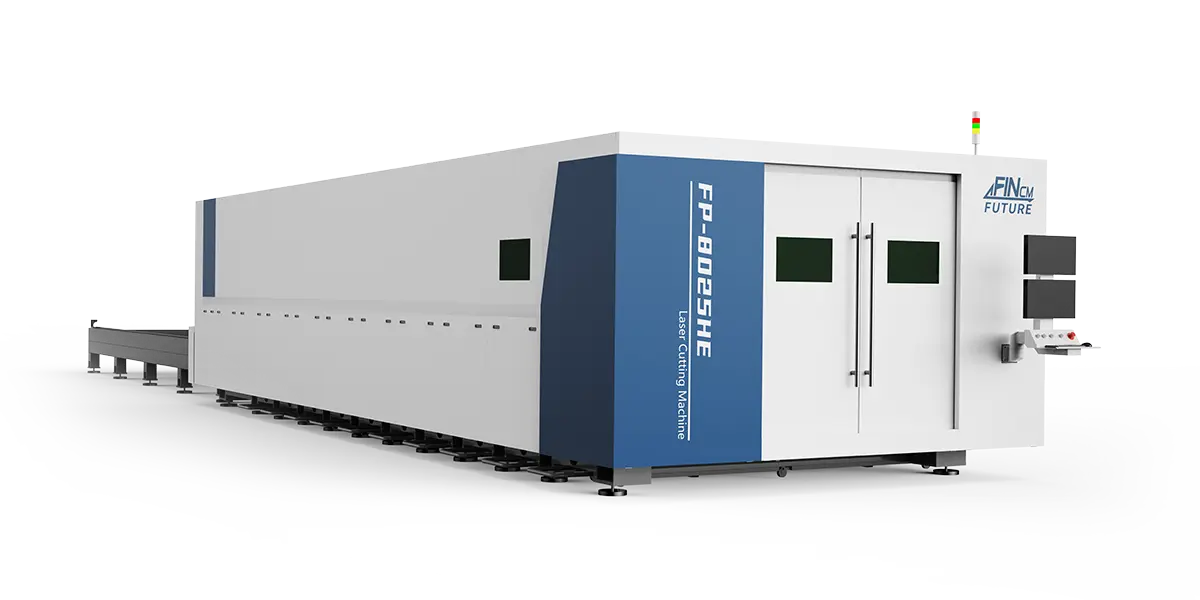

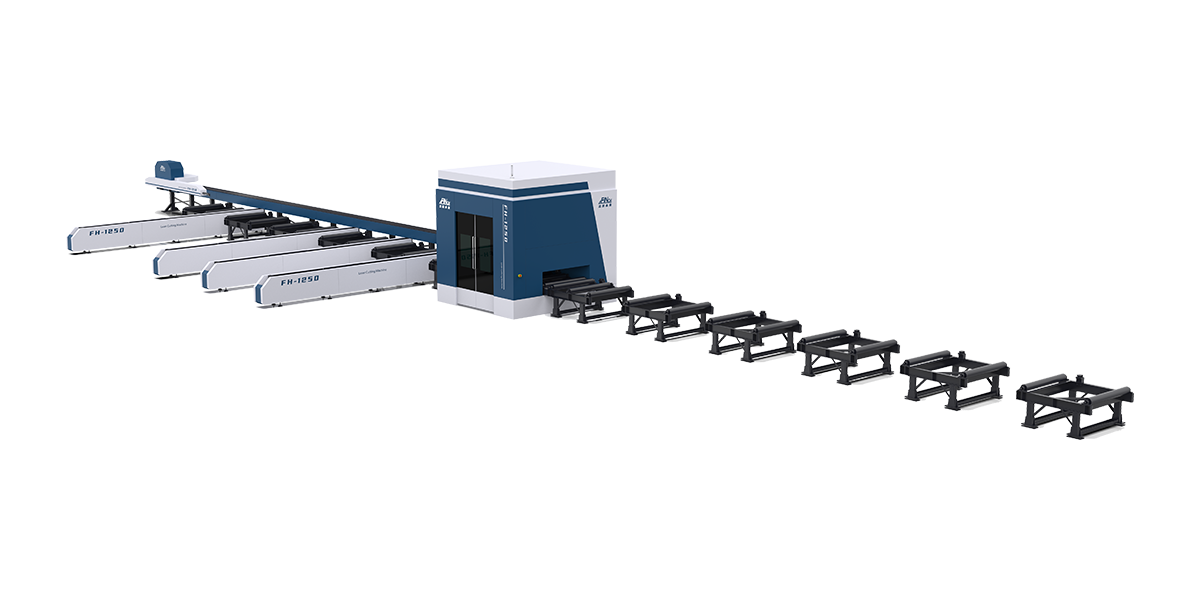

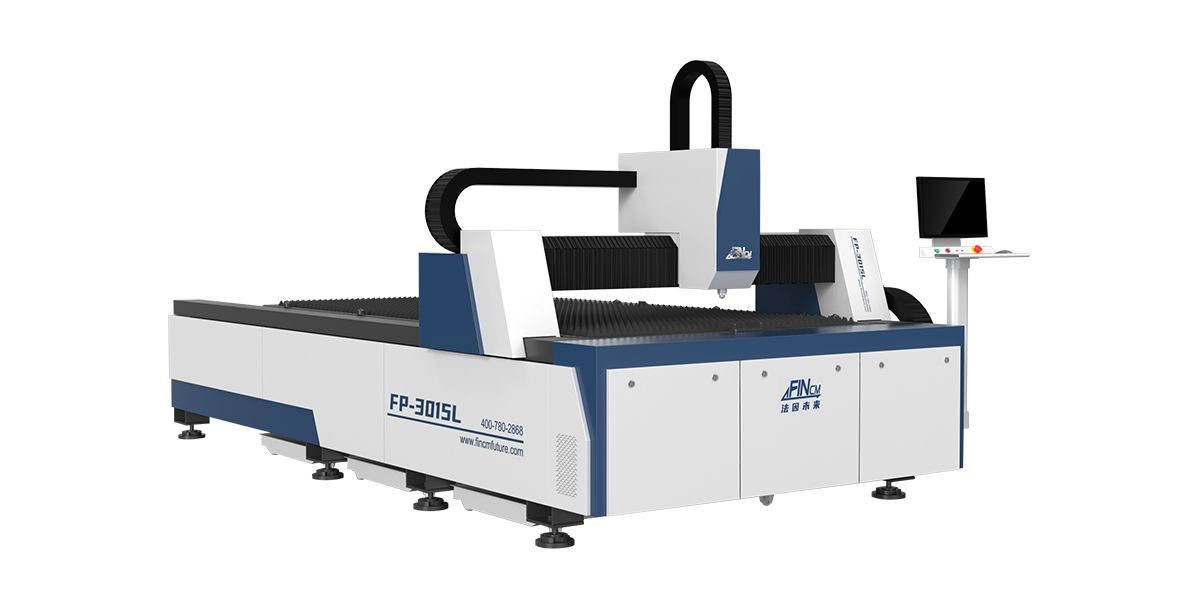

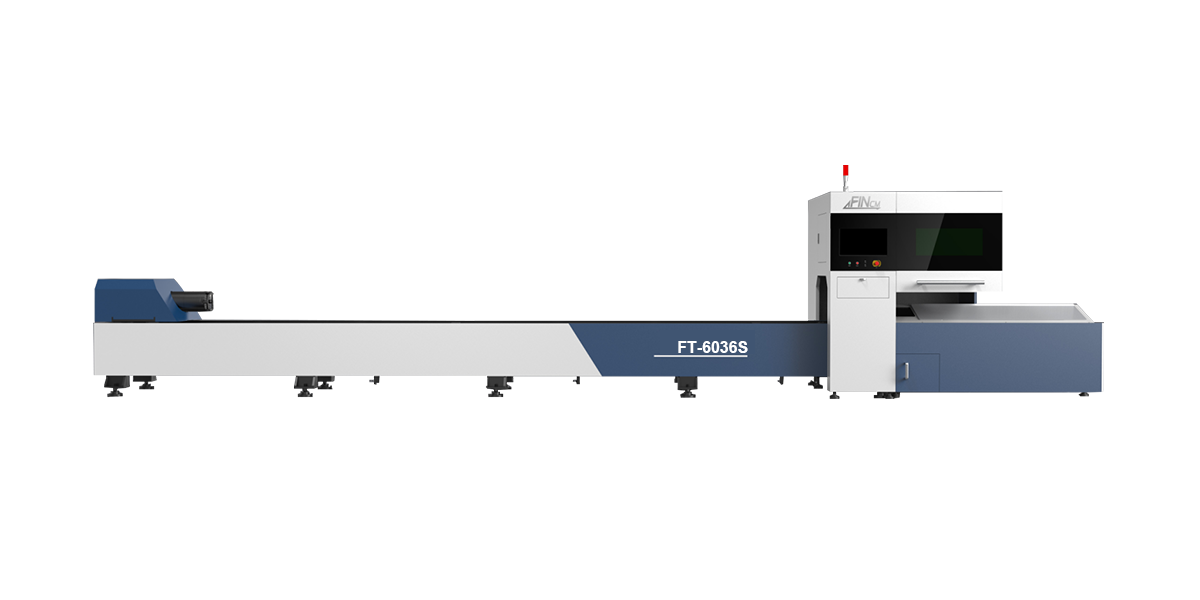

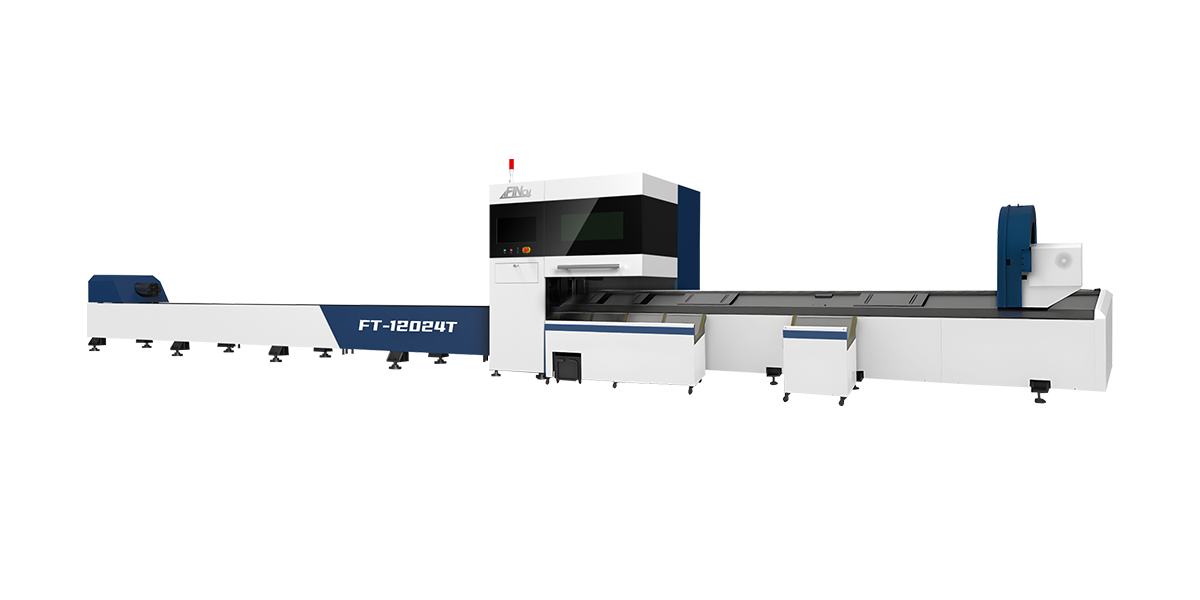

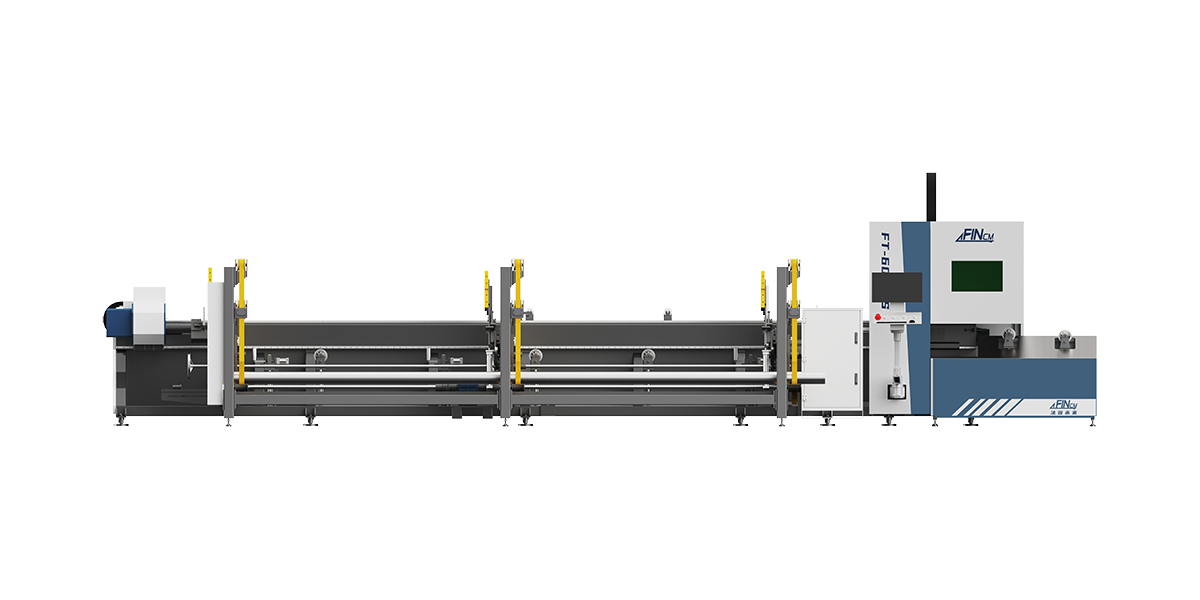

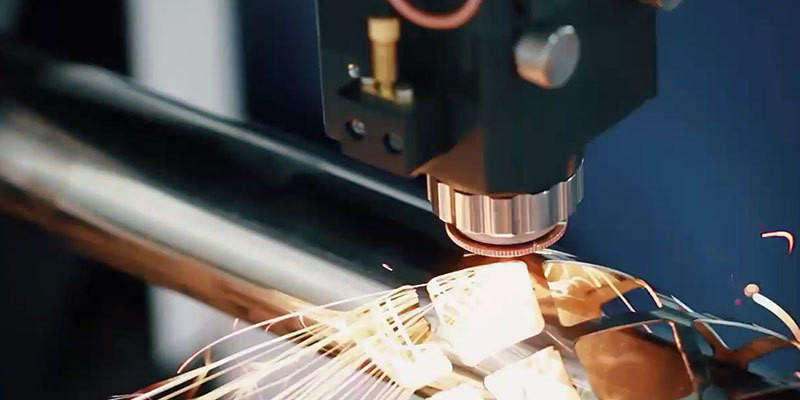

Application of 3. laser cutting machine in new energy industry:

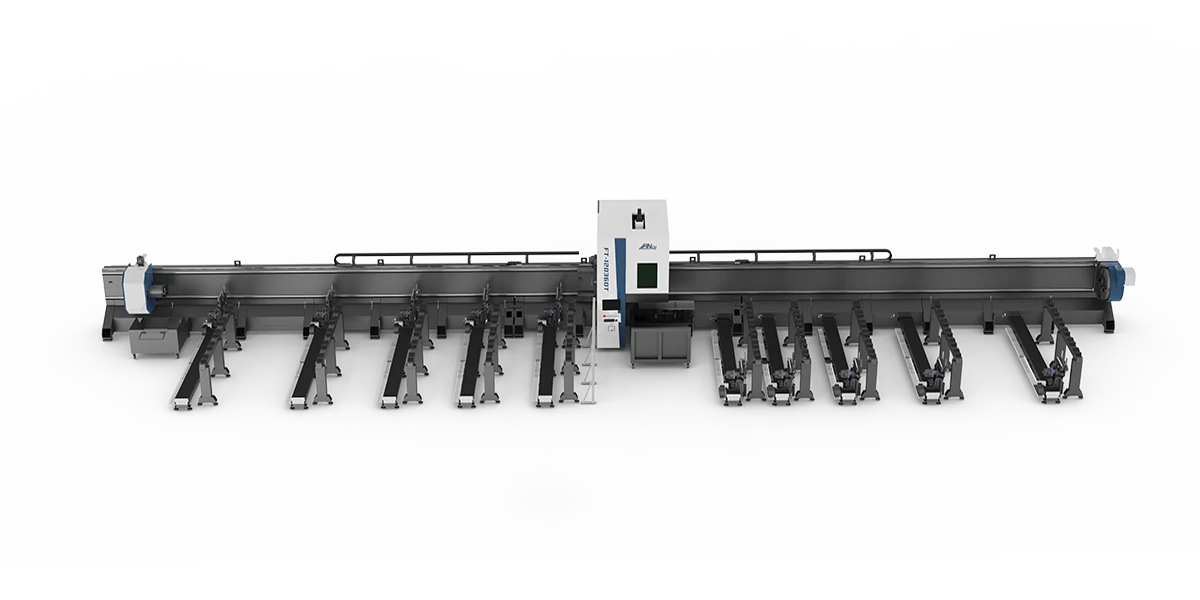

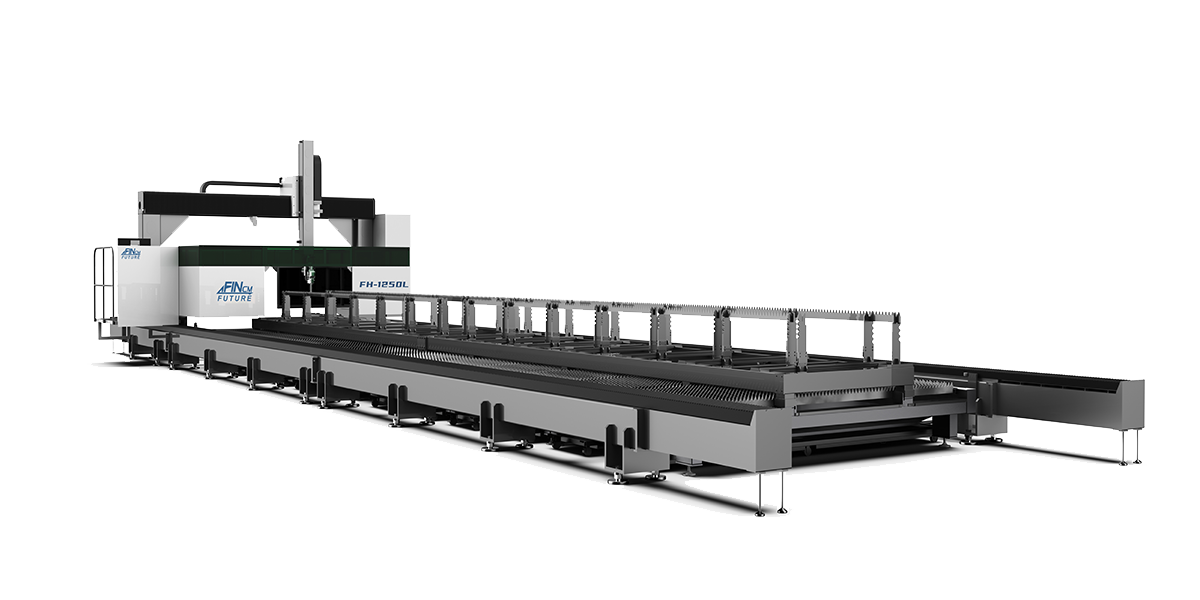

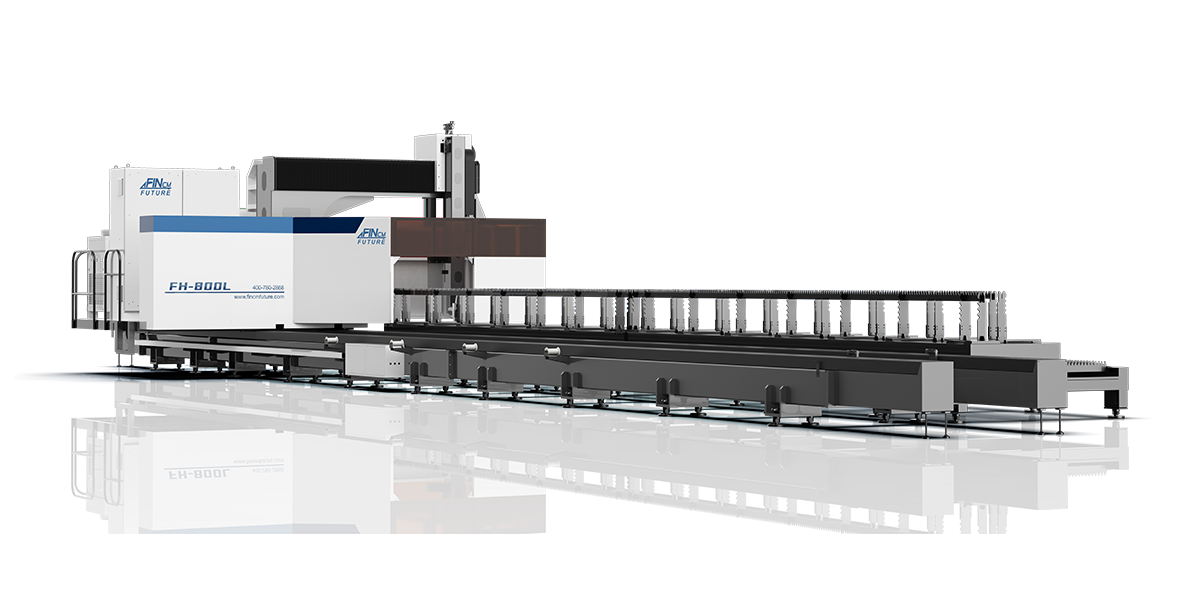

Laser cutting is one of the main laser applications in the field of new energy vehicle manufacturing. Laser cutting technology includes a plane plate laser cutting and three-dimensional space laser cutting, covering China's auto parts, car body, car door frame, car trunk, car roof manufacturing and other management aspects. The application of three-dimensional laser cutting technology in the automobile manufacturing industry is mainly the design and manufacture of automobile bodies. It is widely used in the development of new models, the production of deformed vehicles, the cutting samples of automobile parts, the cutting holes and trimming of body panels, etc.

The development of laser welding technology is the fastest growing track in the new energy automobile industry. Laser welding technology is mainly used in automobile panels, power batteries, PACK modules, etc.

In addition, as China's new energy vehicle companies accelerate their shift to intelligence, the penetration rate of lidar in new cars continues to learn and improve, and it is expected that China will become the mainstream technology application in the future. Lidar combines optical, electronic, mechanical, software, chip, equipment and other technologies, which can help cars perceive the road environment, plan driving routes autonomously, and control vehicles to achieve predetermined goals.

Support

FINCM FUTURE provides you with 24/7 professional services, as well as diversified support plans and expert services to meet your needs from product use, routine maintenance to optimization and upgrading of the whole cycle, so that you can use FINCM products in this process more efficient and economical!