Tower industry

1. industry introduction:

Tower manufacturing industry is a branch of metal structure manufacturing industry. Tower manufacturing refers to the production activities of using iron, steel and other metals as the main materials to manufacture products for power generation, communication, transportation and architectural decoration.

Mainly includes the following types of products: transmission line tower, microwave communication tower, TV tower decoration tower, wind power tower and electrified railway pillar.

As the main areas of use of tower products are the construction of high-voltage and ultra-high-voltage transmission lines and microwave communication networks, tower products mainly include transmission towers and communication towers, of which the most important transmission towers account for about 90% of tower production.

2. industry pain points:

1. The production equipment is left behind and the degree of automation is low.

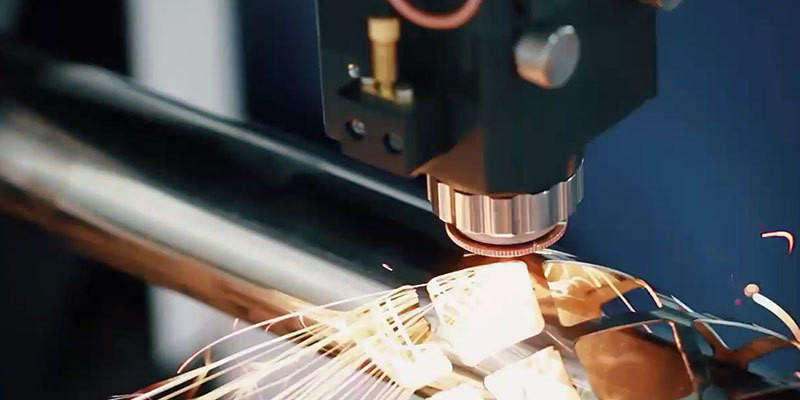

2. The utilization rate of raw materials is low and the amount of waste is large. The cutting of the plate is only the first step in the manufacturing process of the iron tower, which has a significant impact on the subsequent welding. At present, the regular plate cutting processes on the market are roughly divided into: flame cutting, plasma cutting and laser cutting. Flame cutting is a common way of rough machining of steel plates. The cost of cutting equipment is low, but the heat affected zone of flame cutting is much larger, and the thermal deformation is also relatively large. It is impossible to cut non-ferrous metals such as copper and aluminum and stainless steel, and the environmental pollution is more serious. Plasma cutting, wide cutting field, can cut all metal plates, fast cutting speed, high efficiency, and cutting accuracy is higher than flame cutting. However, the large taper of the cutting thick plate and the wide slit will cause a large amount of material waste in the case of batch processing, and will produce harmful gases and a large amount of smoke and dust, causing pollution.

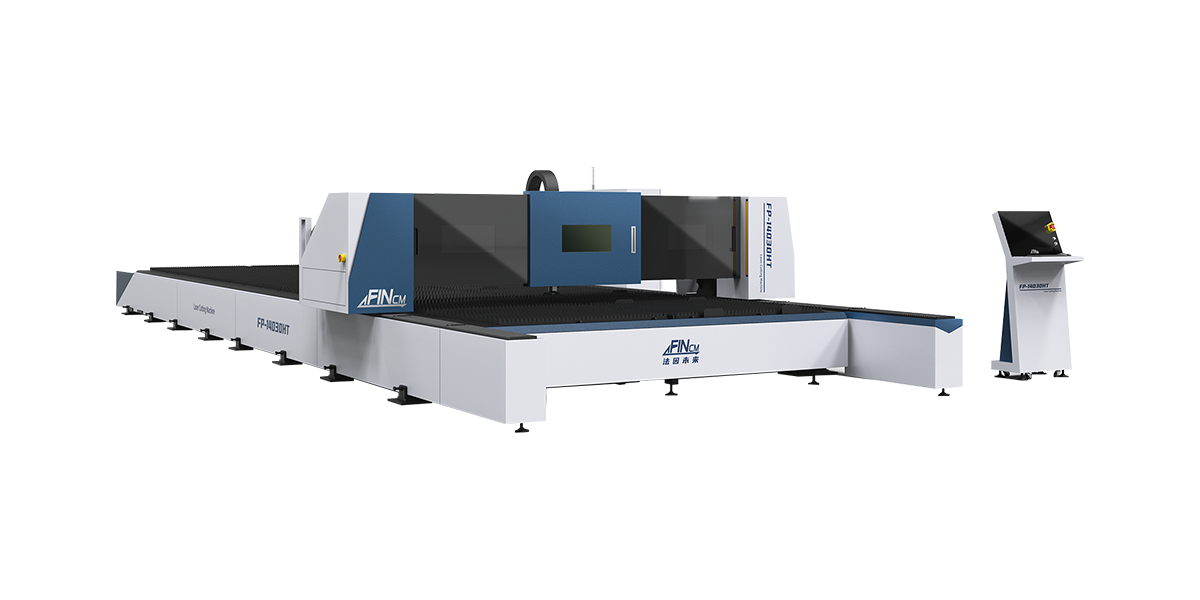

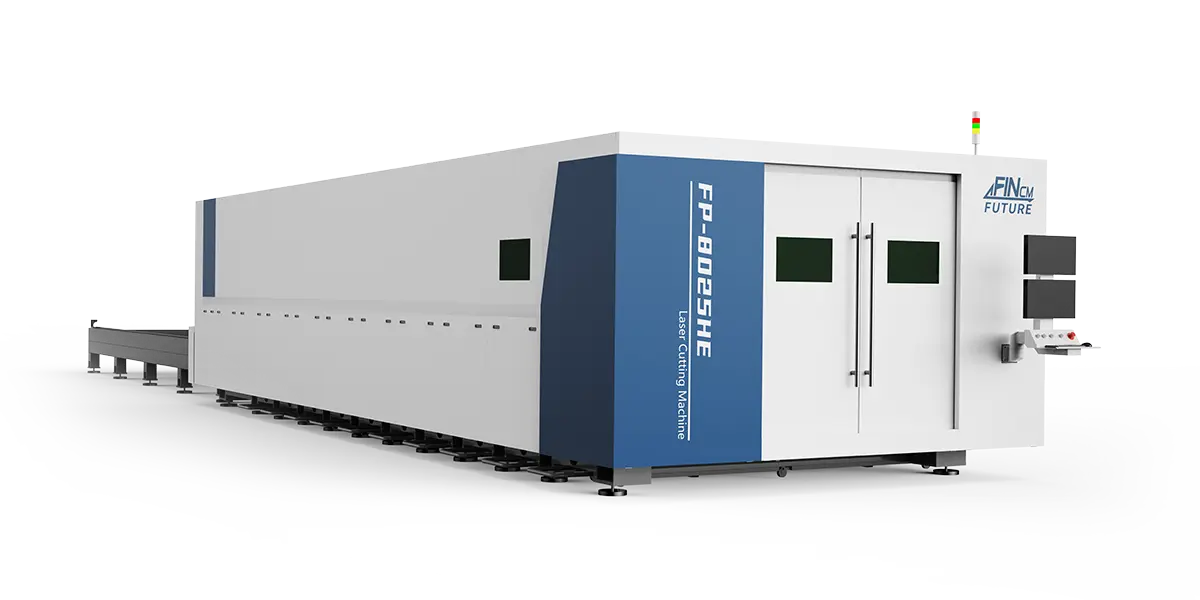

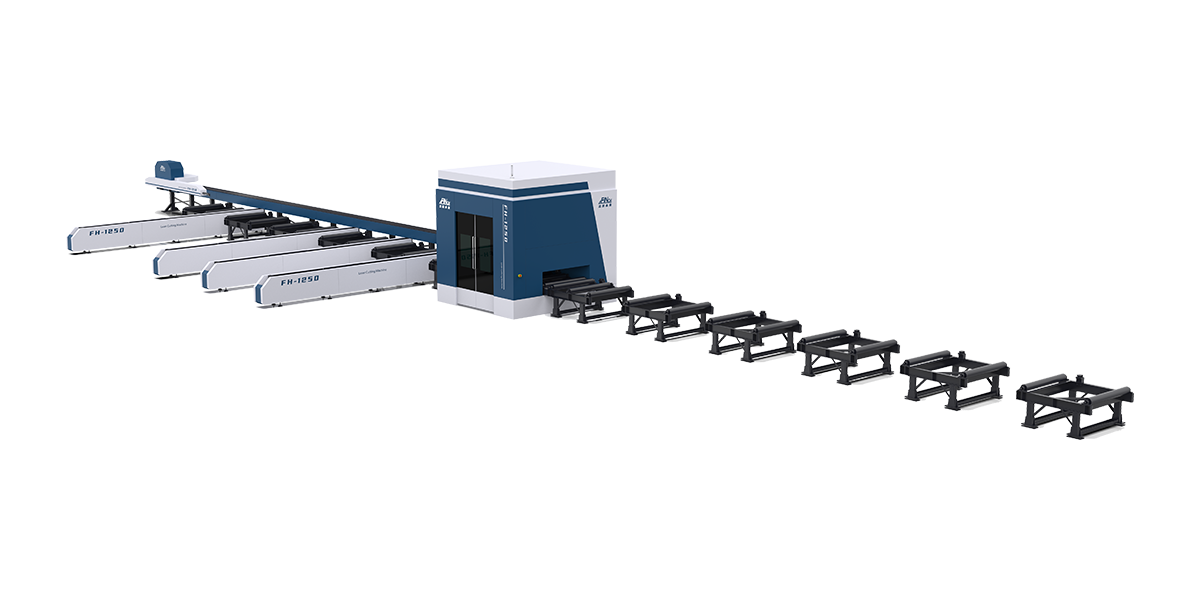

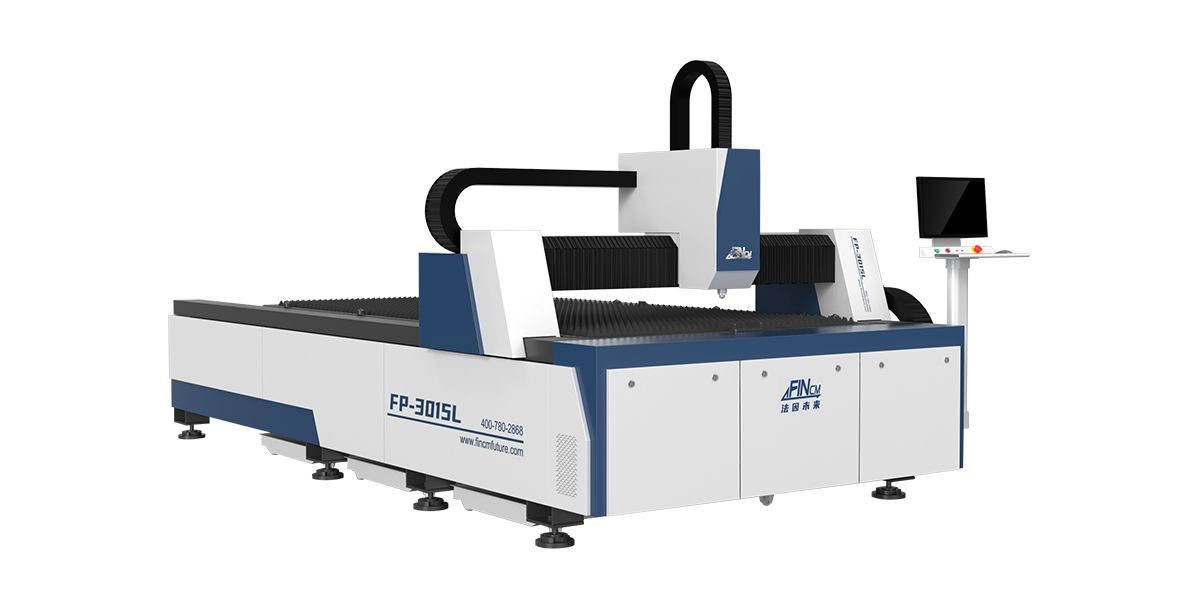

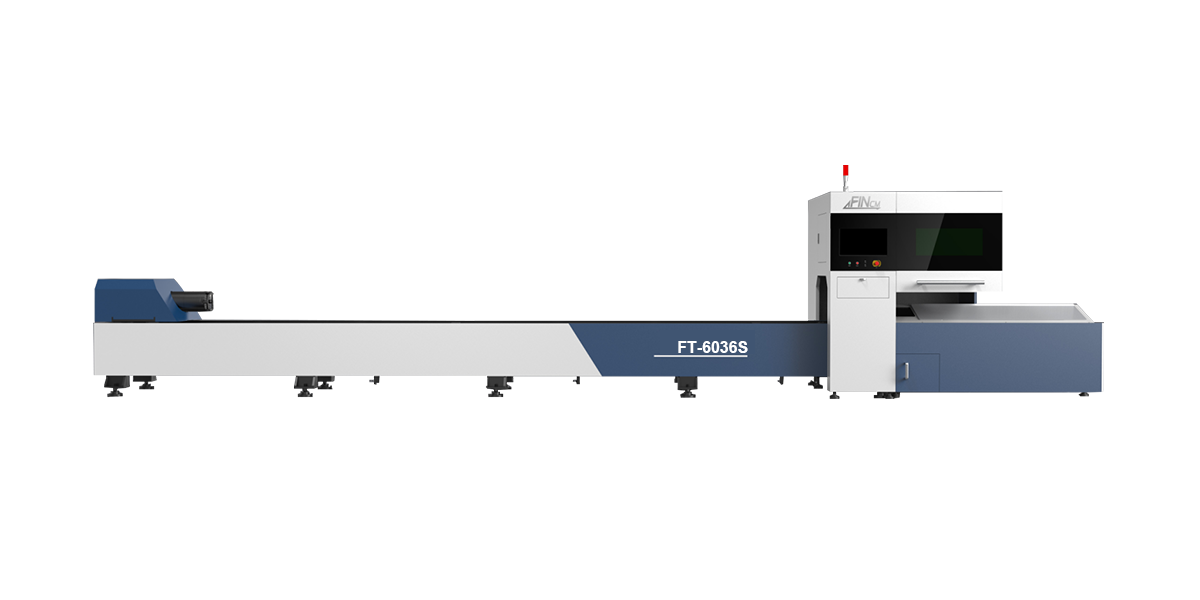

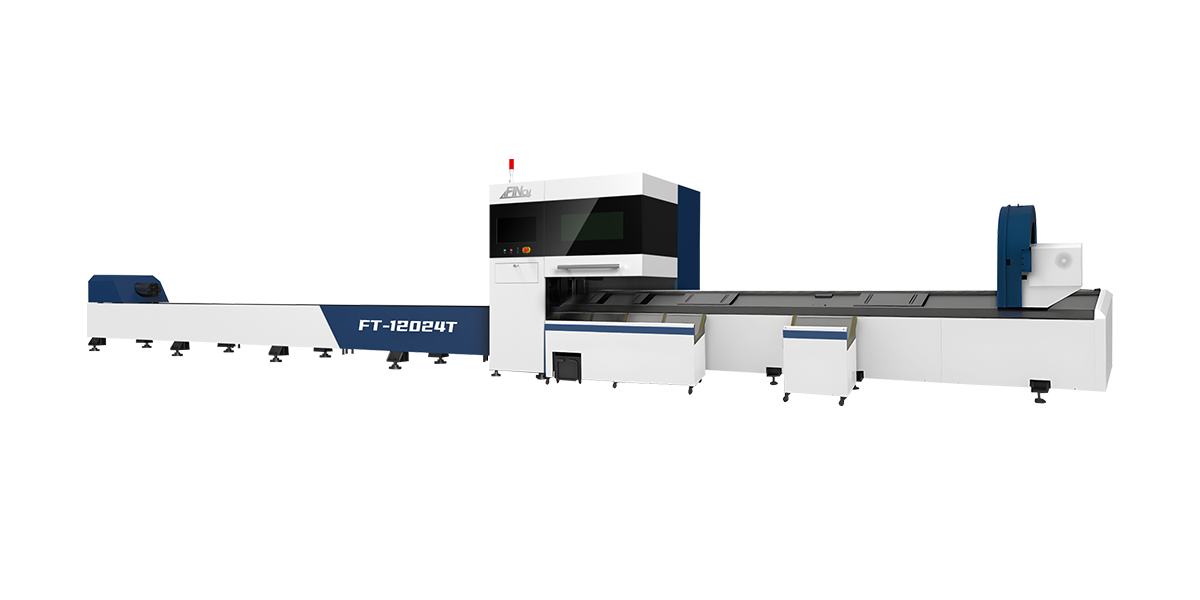

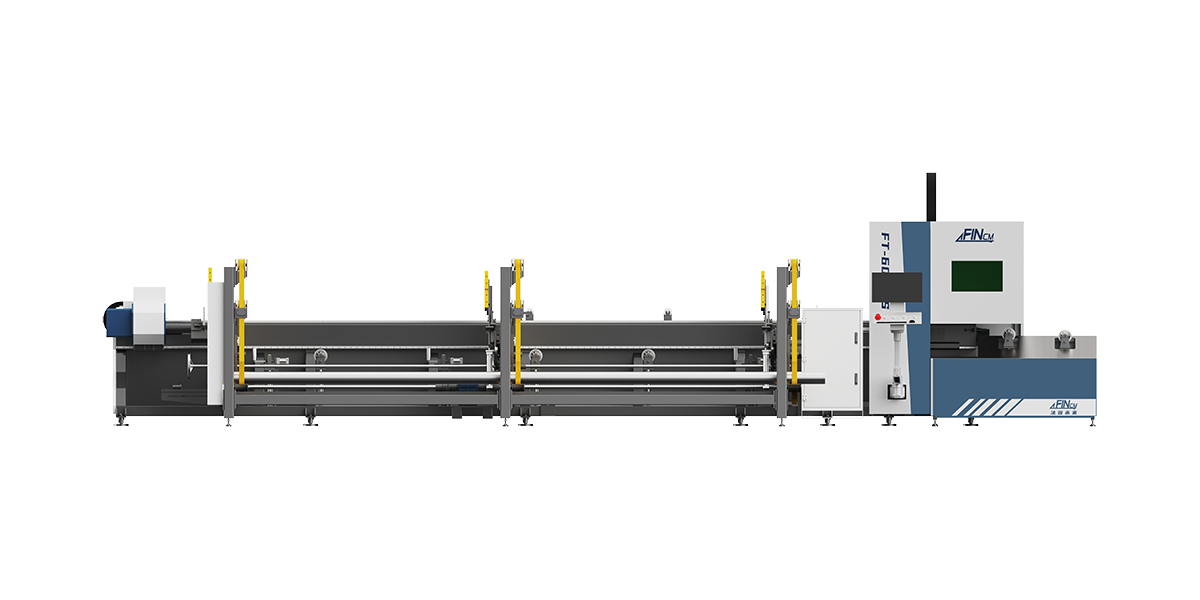

3. laser cutting machine in the tower industry application range:

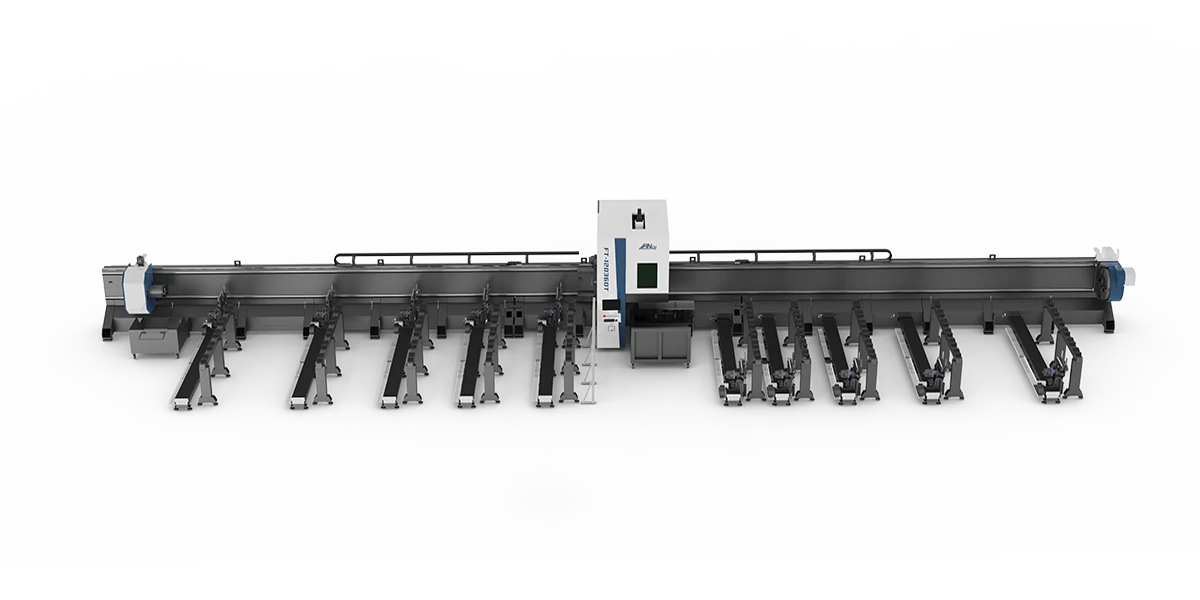

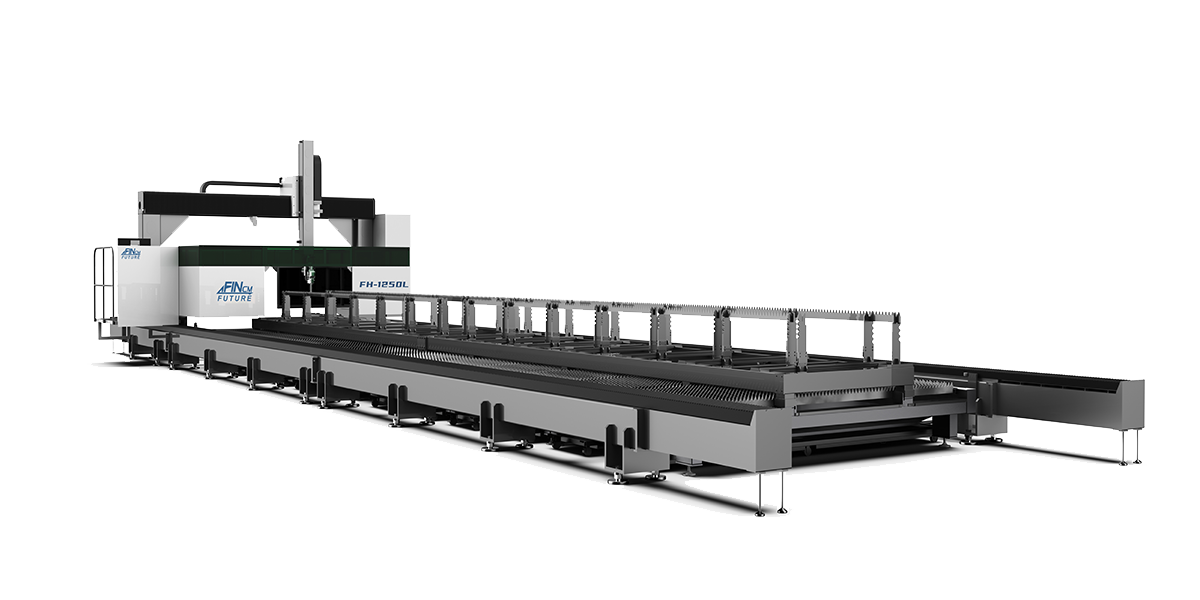

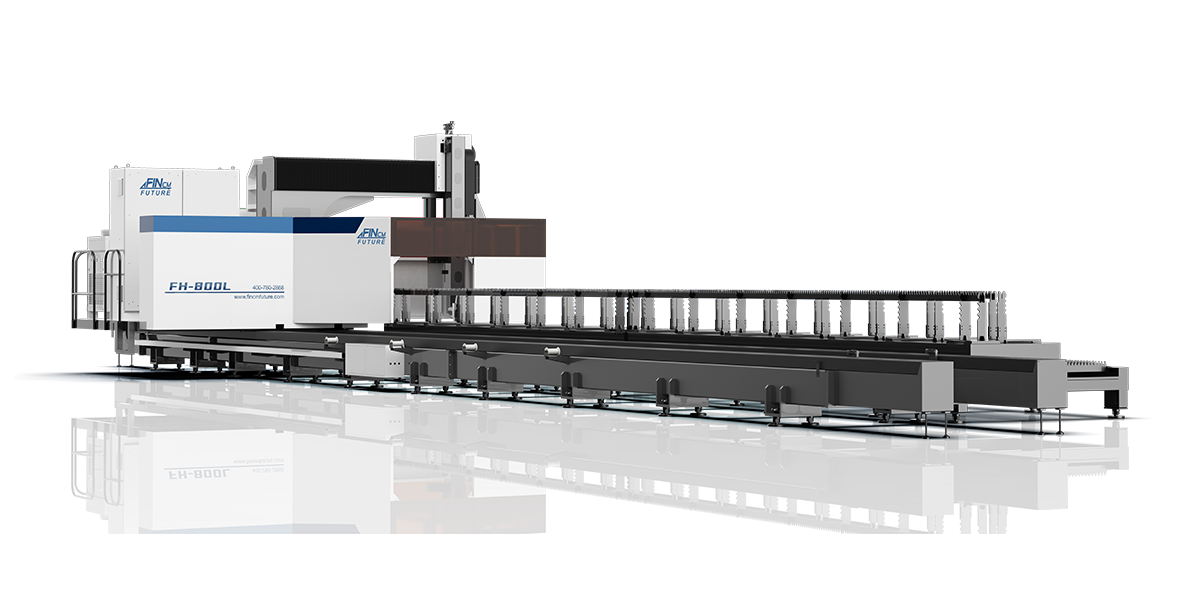

Common themes in the tower industry: China's transmission towers generally use angle steel towers (about 20-70 meters high), or transmission towers (generally more than 100 meters) use combined angle steel towers or steel pipe towers. With the continuous upgrading of modern power grid, the cross section of transmission tower has also evolved, especially with the construction of multi-loop engineering and large cross-section engineering on the same tower, the load of the tower is getting larger and larger, and the cross section of the rod has developed from single angle steel to double-spell angle steel, four-spell angle steel, lattice structure, steel pipe and other profiles.

Compared with flame cutting and plasma cutting, laser cutting has more obvious advantages. It can combine highly concentrated energy and pressure to cut smaller material areas, manufacture more parts through intensive cutting, and reduce material waste. The cutting accuracy is higher, the heat affected zone is small, and it is not easy to deform. The cutting seam shall be smooth and beautiful without subsequent grinding treatment. Laser cutting can do punch difficult to complete the complex process.

Support

FINCM FUTURE provides you with 24/7 professional services, as well as diversified support plans and expert services to meet your needs from product use, routine maintenance to optimization and upgrading of the whole cycle, so that you can use FINCM products in this process more efficient and economical!