Construction machinery industry

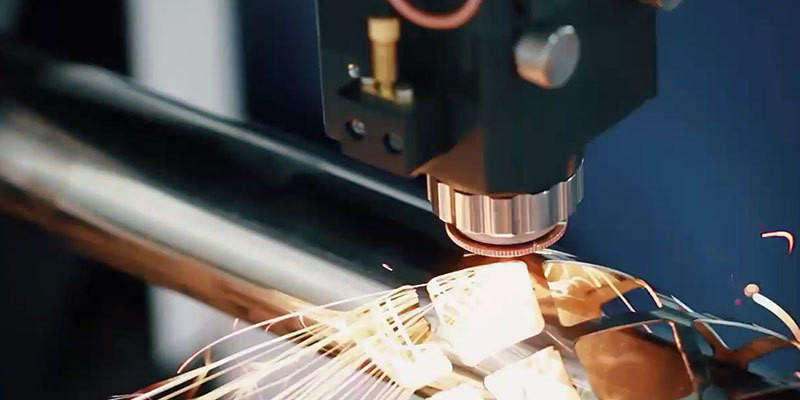

Laser cladding is currently mainly used in the manufacturing process to repair damaged products and modify the appearance of materials. The laser cladding method can also be used as a vehicle commutator, gear and other components processing. Mold and roll processing is also widely used in laser cladding method to improve the surface hardness, abrasion resistance, high temperature resistance and other properties, to extend the use of time. The laser cladding method has also been successfully used to repair components such as engine blades, vehicle crankshafts, molds, etc. The performance of the repaired components can reach or even exceed that of new products, while the cost is greatly reduced.

Automobile manufacturing industry

The importance of automobile manufacturing industry is self-evident. It not only provides convenience for people, but also contributes to social and economic development. Therefore, the development of the automobile manufacturing industry should be better improved and strengthened. Only through continuous technological innovation and efficient production methods can the automobile manufacturing industry have a longer-term and sustainable development prospects and make more contributions to the development of human society.

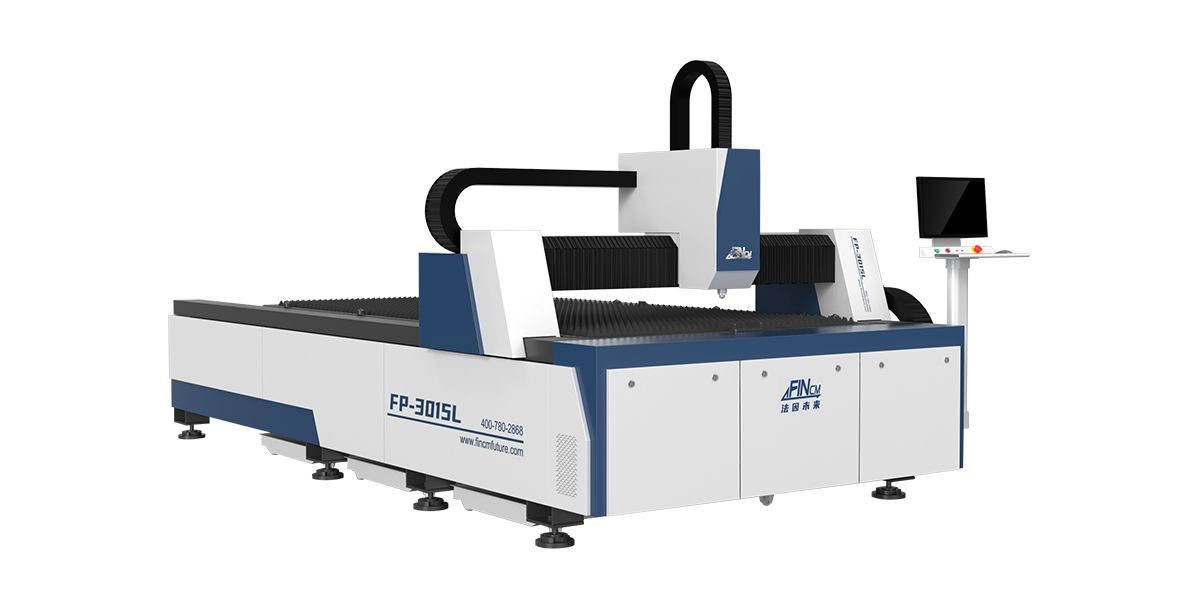

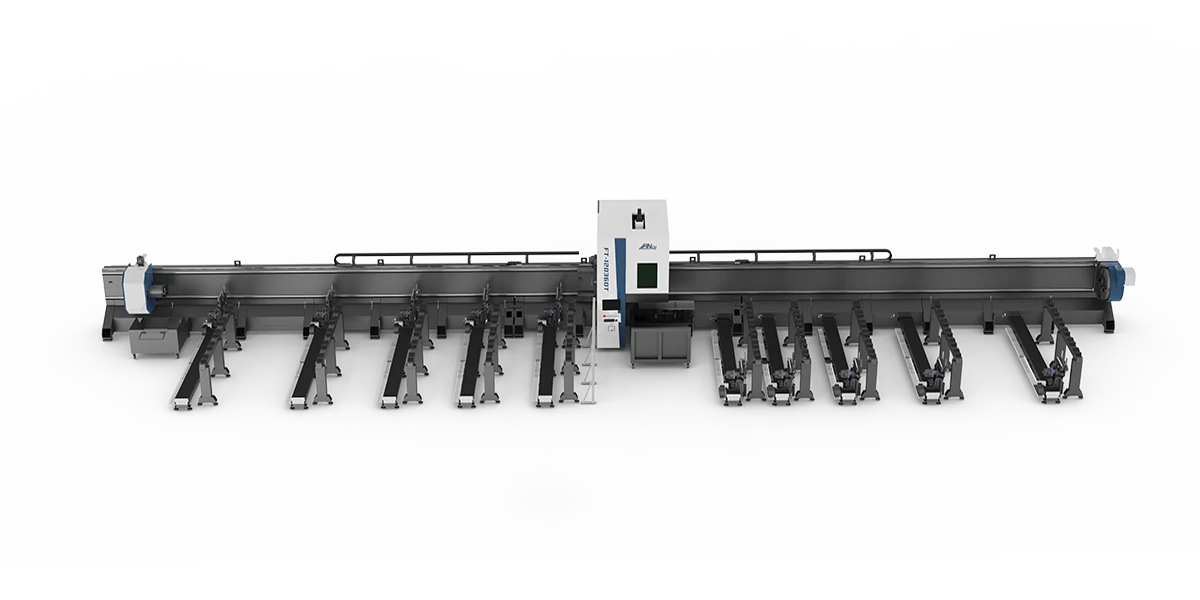

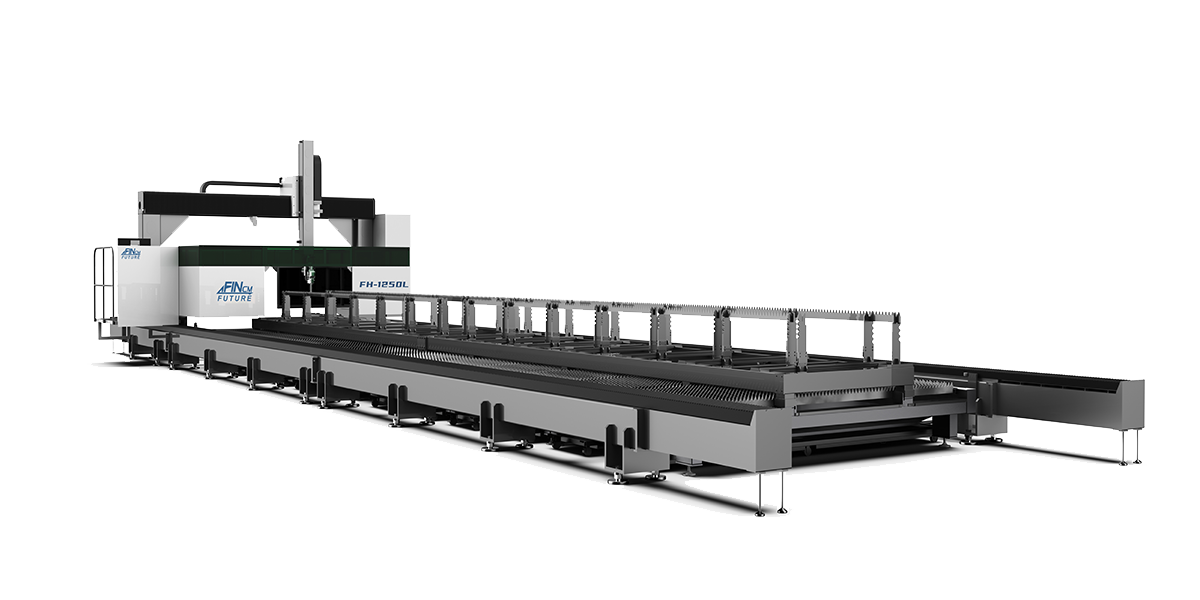

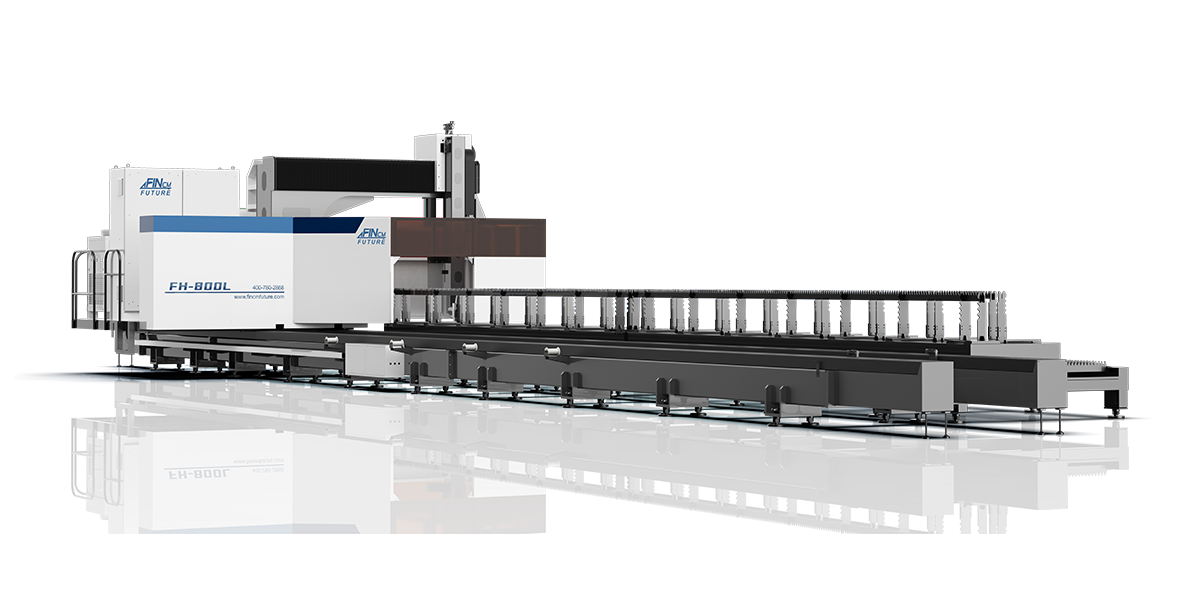

Steel prices have also developed rapidly in recent years. At present, many steel structure industries have used laser cutting machines to save a lot of raw materials. Many steel structure enterprises have abandoned flame cutting and turned to laser cutting. Laser cutting is clean and environmentally friendly, which is also in line with relevant national environmental protection policies. Laser cutting machines generally use air for thin plates, oxygen for thick plates, and acetylene for flame cutting, thus greatly reducing costs.

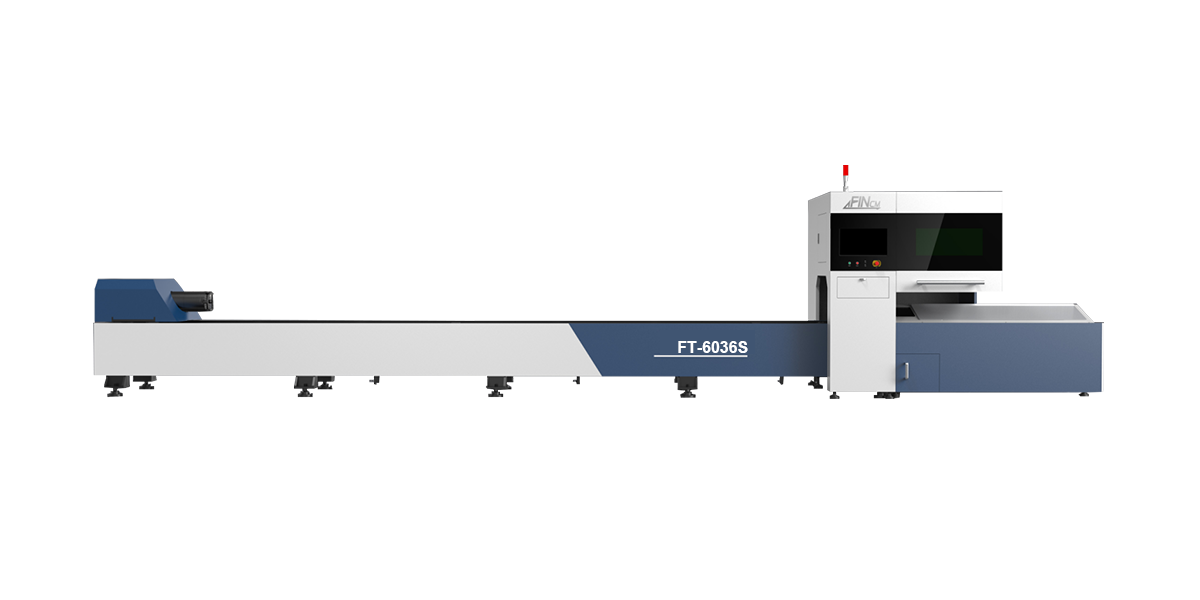

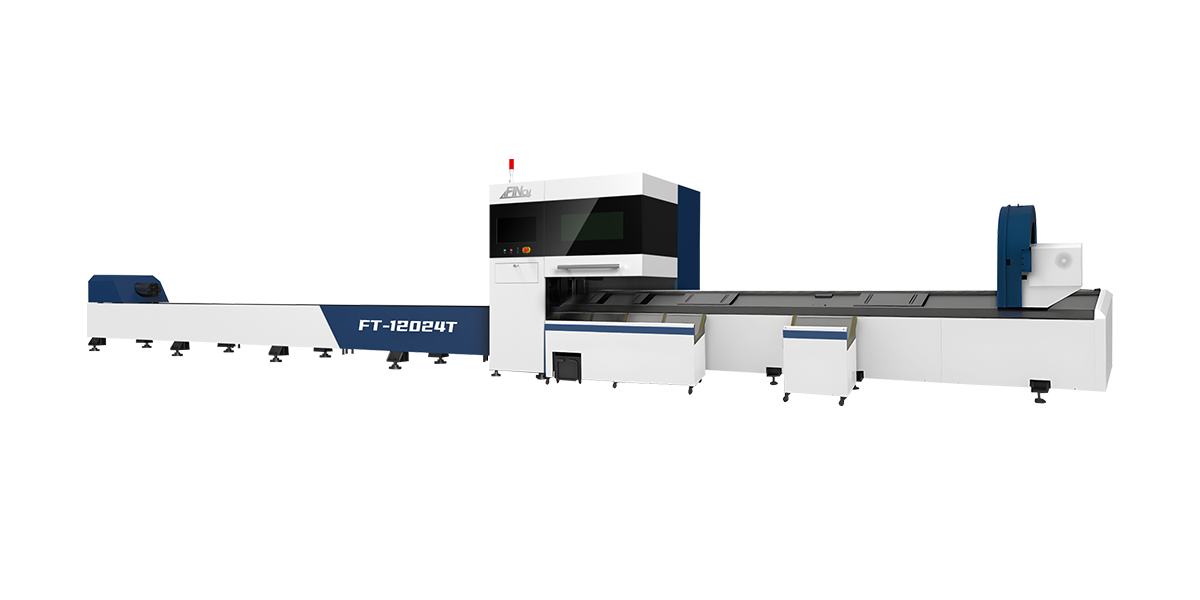

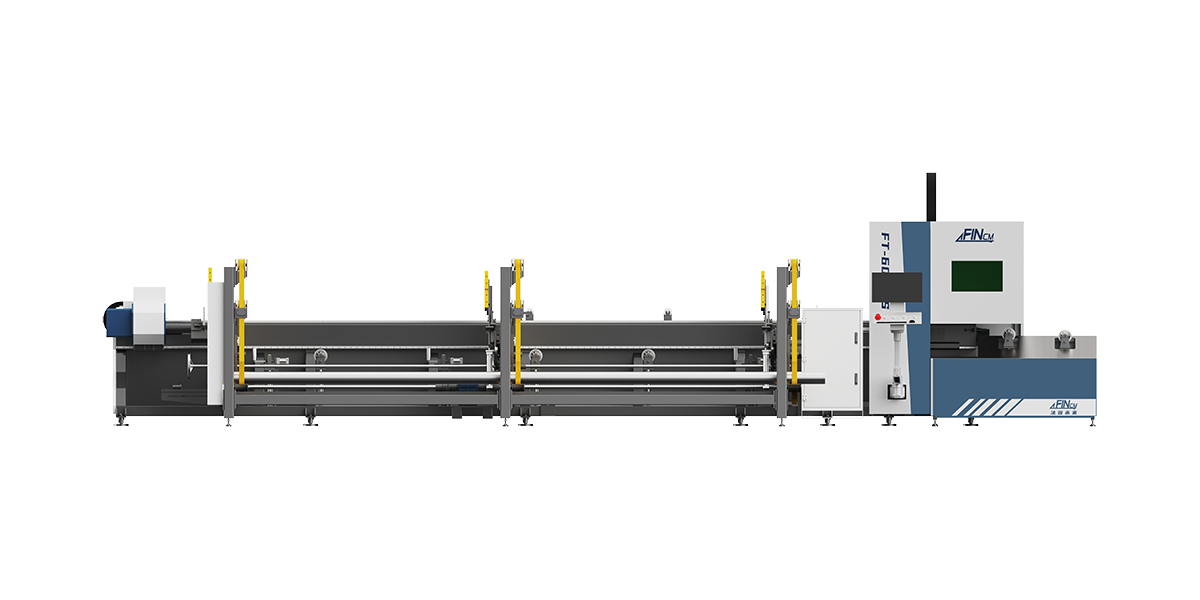

Common themes in the tower industry: China's transmission towers generally use angle steel towers (about 20-70 meters high), or transmission towers (generally more than 100 meters) use combined angle steel towers or steel pipe towers. With the continuous upgrading of modern power grid, the cross section of transmission tower has also evolved, especially with the construction of multi-loop engineering and large cross-section engineering on the same tower, the load of the tower is getting larger and larger, and the cross section of the rod has developed from single angle steel to double-spell angle steel, four-spell angle steel, lattice structure, steel pipe and other profiles.

Laser cutting is one of the main laser applications in the field of new energy vehicle manufacturing. Laser cutting technology includes a plane plate laser cutting and three-dimensional space laser cutting, covering China's auto parts, car body, car door frame, car trunk, car roof manufacturing and other management aspects. The application of three-dimensional laser cutting technology in the automobile manufacturing industry is mainly the design and manufacture of automobile bodies. It is widely used in the development of new models, the production of deformed vehicles, the cutting samples of automobile parts, the cutting holes and trimming of body panels, etc.

In the post-epidemic era, the non-epidemic medical device market recovered rapidly. Coupled with the structural changes in the population and the improvement of health awareness, China's medical device industry as a whole has entered a stage of rapid growth. From the perspective of the industrial chain, the upstream is dominated by various raw material suppliers and corresponding technology research and development enterprises. Midstream to all kinds of medical equipment, consumables related manufacturing enterprises. Downstream is dominated by various medical institutions, scientific research institutions, third-party inspection centers and C- end users. The construction of the domestic medical device industry chain is relatively perfect, and will gradually penetrate into the more high-end market in the future.

Support

FINCM FUTURE provides you with 24/7 professional services, as well as diversified support plans and expert services to meet your needs from product use, routine maintenance to optimization and upgrading of the whole cycle, so that you can use FINCM products in this process more efficient and economical!